piSAFE® – Now Even Safer

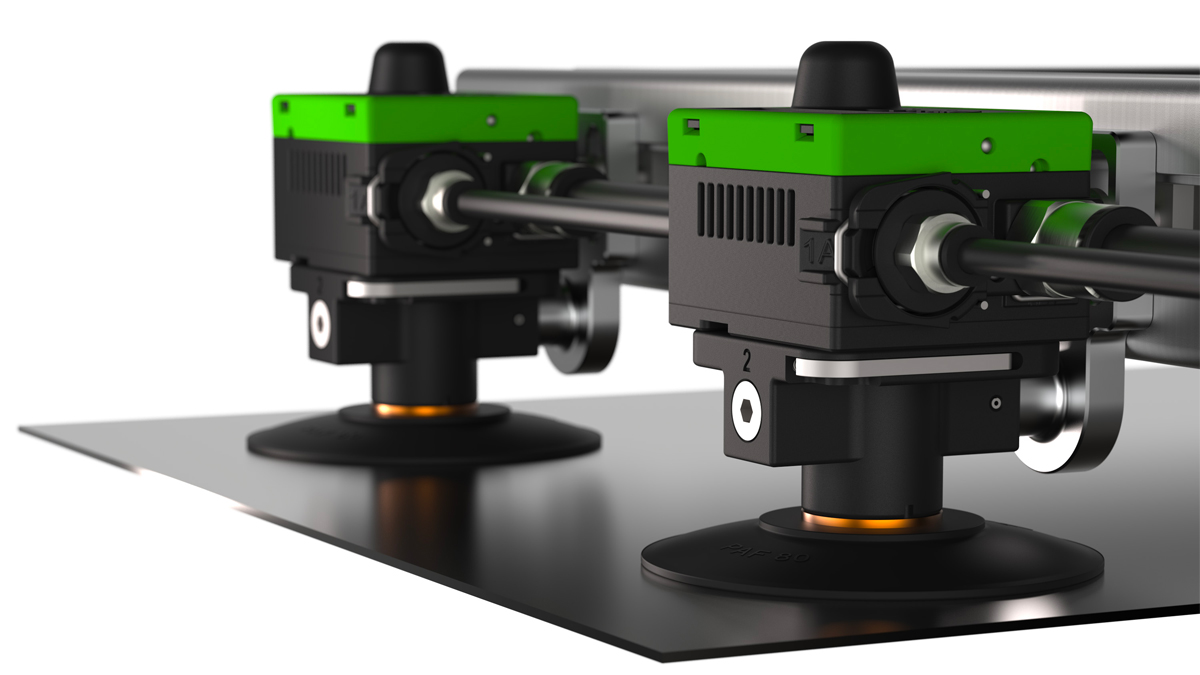

piSAFE® has for some years been a highly appreciated member of Piab’s assortment of products with elevated safety functions. As the reliable vacuum pump is now upgraded, the safety focus remains. However, versatility and sustainability have been added to the mix as new healthy prerequisites.

Since its introduction in 2021, piSAFE® has clearly been the vacuum ejector of choice where an exceptionally high level of gripping safety is necessary for a stable manufacturing process. The key feature being the vacuum safety valve which maintains the vacuum level in the COAX® based pump at all times.

This quality has made piSAFE® especially appreciated in demanding automotive applications such as glass and body assembly, where a dropped part would have severe consequences.

As the offered safety level was already satisfactory, other prerequisites were added to the list when piSAFE® went for its recent 2.0 tour through Piab’s R&D department.

The piSAFE® concept is now divided into four fully configurable products, to enable the customer to freely choose a suitable level of functionality:

- piSAFE® – fully equipped pump unit with safety functions.

- piSAFE® Vacuum Safety Valve (VSV) – same safety functionality, to be used with external vacuum pump.

- piSAFE® Vacuum Safety Valve MINI (VSV MINI) – safety functions in a minimized format

- piSAFE® Mounting bracket – Versatile bracket to be used with piSAFE® products, other systems like our piSTAMP®, or just to be used as suction cup holder for external vaccum sources.

Consequently, the configurator has been updated accordingly with one product card for each of the four products. Apart from the product split, the new version of piSAFE® has undergone the following improvements:

VSV – Common feed using atmospheric quick release (AQR NC) which means one hose for both feed and release, instead of one for each. Supports increased compatibility, easier installation and less maintenance.

Silencer now optional for a healthier work environment. Protects the hearing of staff involved in the every-day process.

New attachments available – 32 mm ball joint, 16 mm lock pin and a special level compensator. The latter possible to configure as fit-to-purpose.