Problem: Cost of Air Leaks

We often hear that the cost of air in a manufacturing facility is approximately 40% of a utility bill. Obviously this will vary considerably for different companies. There are a couple of things that one could do to save thousands of dollars each year. First, many companies have their air compressor installed way off in a corner somewhere with too small of airline feeding the system. They then turn up the pressure on the air compressor to get the required results. Most air tools and pneumatic components are rated for 90 psi. Running a compressor anywhere from 125 to 165 psi is a total waste of energy. The airline should be sized much larger and be used as the receiver instead of an extra air tank at the far end of the line. A pressure drop of 10 psi per 100 feet instead of 1 psi per 100 feet is about a 10% additional cost of energy every day.

Secondly, the cost of air leaks goes up proportionally to the pressure. Sometimes companies will turn off the air over the weekend or during downtime because of all the air leaks. One of the problems in doing this is that it causes more air leaks. When the air regulators are turned to a fairly high setting and the air pressure is then turned off, there will be a high spring force that is pushing on the diaphragm with no counterforce from the air. This is very hard on the air regulators, and they will also start to leak. All the air regulators should be turned down before shutting off the air so the diaphragms don’t get damaged.

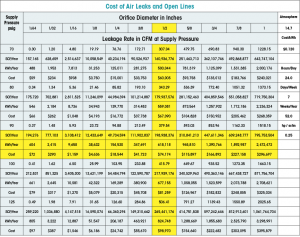

Question: Using the chart below, how much does it cost to have 1/8″ air leak for a year at 90 psi and at 125 psi? Also, how much would 31.54 scfm cost to run at 125 psi for a year? This chart is based on $0.12 / kilowatt.

(Click on image to enlarge)

Find Out The Solution

Cost of a 1/8″ diameter air leak for a year at 90 psi is $4.636.00.

Cost of a 1/8″ diameter air leak for a year at 125 psi is $6,186.00.

Cost of 31.54 scfm for a year:

31.54 x 60 minutes per hour = 1892.4 cubic feet per hour

1892.4 x 24 = 45,417.6 cubic feet per day

45,417.6 x 365.25 days per year =16,588,778.4 cubic feet per year

Looking on the chart under 1/8″ at 125 psi = approximately $6,186.00 per year.

Deadline past. Not available for submissions.

Winner:

Brandon Trahan, CFPMM, CFPMHT, Western Hydrostatics, Inc., Riverside, CA

By Ernie Parker, AI, AJPP, AJPPCC, S, MT, MM, MIH, MIP, MMH,

Fluid Power Instructor, Hennepin Technical College, EParker@Hennepintech.edu

This teaser is printed in the Fluid Power Journal. Those who submit the correct answer before the deadline will have their names printed in the Society Page newsletter and in Fluid Power Journal. The winners will also be entered into a drawing for a special gift.

Hello,

I’d like to ask what equations were used to calculate these values? I’m just having a hard time distinguishing between if these values are ACFM or SCFM.