Replace or Restore? Why You Should Retrofit that Aging Press

By Mike Kramer, Press Application Engineer, Bosch Rexroth

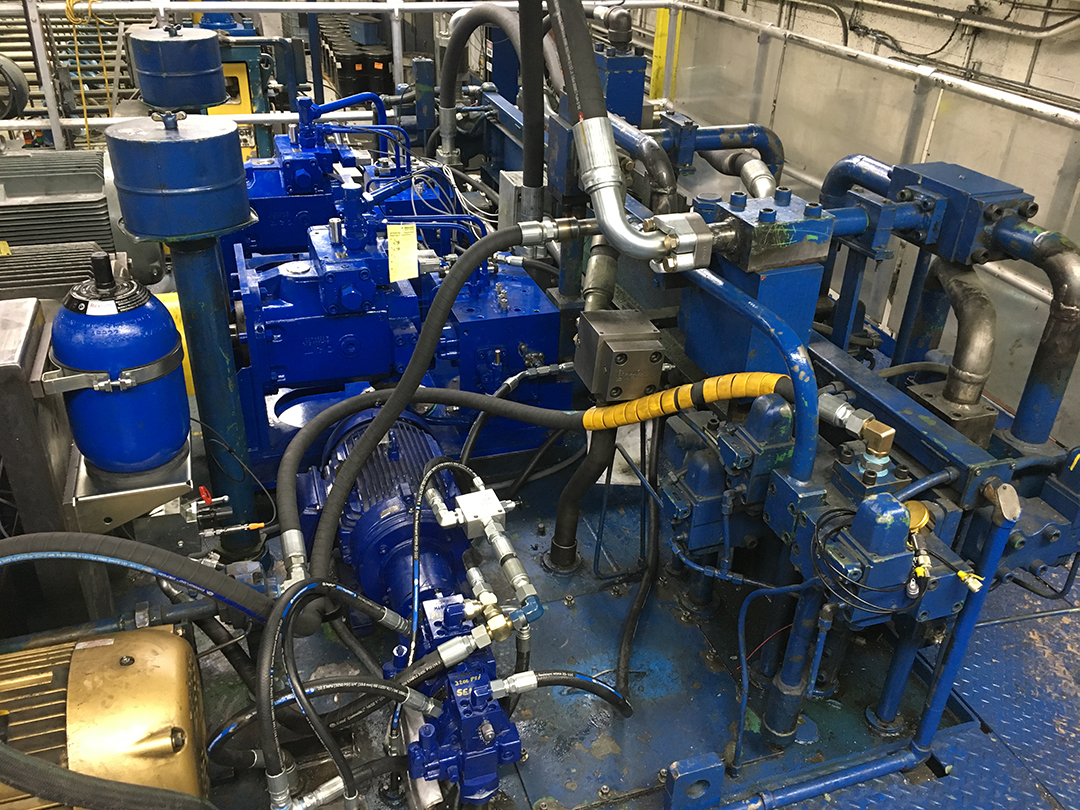

One of the most productive and hardworking machines in the industry today is the extrusion press. With proper maintenance and life-cycle management, many extrusion presses operate productively for decades, often with their original hydraulic pumps, control valves, and other components. However, this longevity leads to persistent complications; many extrusion presses are using outdated, inefficient, and unreliable hydraulic pumps.

Rather than replacing the entire press, there are strategic cost savings and performance advantages that can be realized by retrofitting legacy hydraulic systems on many of today’s presses. These include significant reductions in energy consumption and measurable improvements in press throughput. Replacing outdated working systems can dramatically reduce downtime, maintenance, and repair costs, especially when replacing hard-to-obtain components such as older hydraulic pumps and valves.

Equally important, the newest generation of high-pressure

variable displacement pumps and pump control systems incorporate smart technologies and connectivity that make it easier to implement

Industry 4.0 capabilities such as advanced diagnostics, predictive

maintenance, and real-time production data collection.

A retrofit increases performance and decreases maintenance frequency.

Risk factors of aging press hydraulics

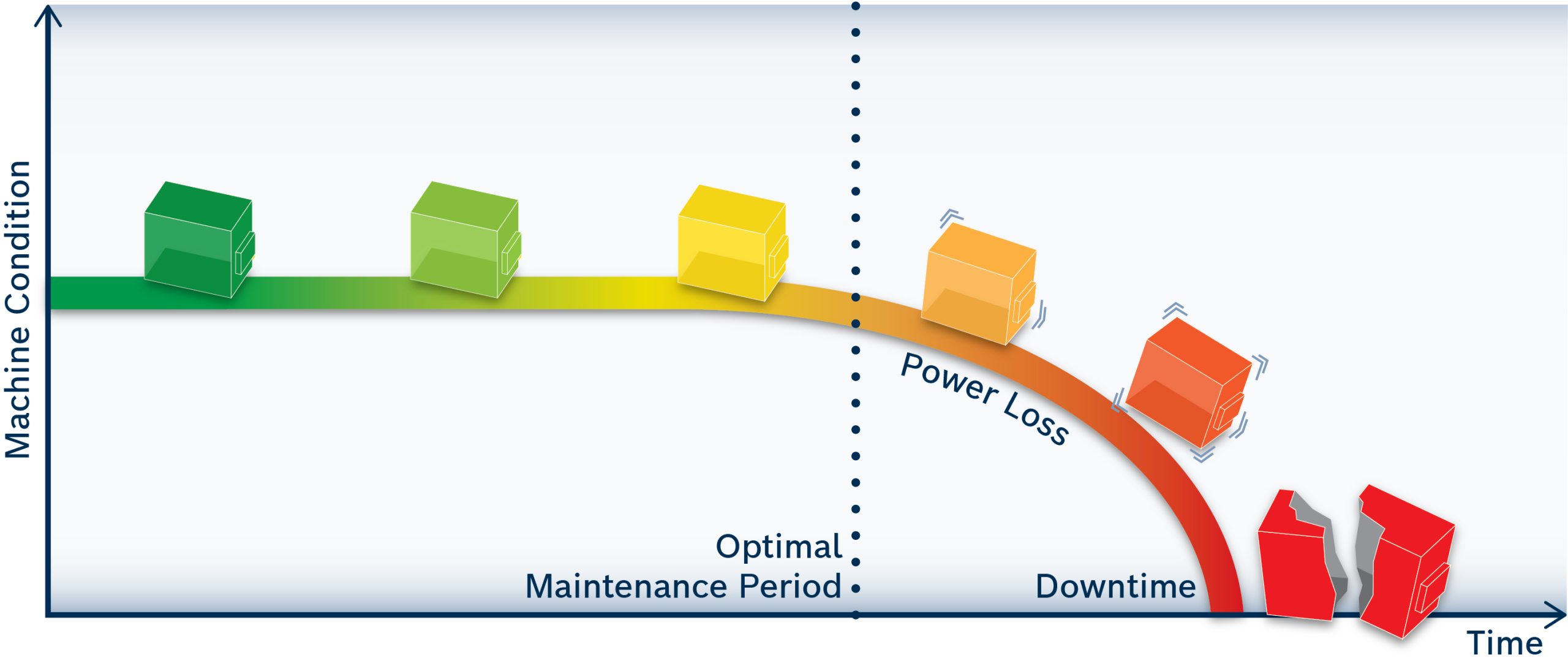

As they age, even the best-maintained presses hit a point where retrofitting or replacement of critical components starts to make both operational and economic sense. The initial symptoms may simply be more frequent downtimes to replace or service malfunctioning equipment.

There is also loss of press performance due to hydraulic fluid leaks, which lead to safety and environmental hazards that take time to remedy. At one Midwest extrusion press, hydraulic pump oil leaks caused an estimated 65 to 70 hours of downtime every year to repair. From constant welding to fabricating new pipes and connections for a fifty-year-old pump when parts were no longer available, the cost and downtime of trying to keep the legacy equipment alive became prohibitive.

As technology advances, a 1960s-era press may not be able to produce newer parts that meet current requirements. Modern automotive parts are an excellent example: metal used in today’s cars and trucks is significantly different from that used several decades ago, and it now includes a growing percentage of aluminum extrusions. These new alloys bring unique requirements for processing and forming to automotive standards that presses of an older era cannot accommodate, including accurate control of extrusion velocity and force.

Based on the current age and performance of presses with legacy hydraulics, manufacturers should analyze all available data to identify pain points and determine the value of a retrofit for their operations. Weighing these factors, here are key reasons why a retrofit may be the right path forward.

Upgrading technology can quickly improve performance. In certain cases, switching from older technology may be the best move for machine performance. For example, upgrading the hydraulics in an existing machine from traditional hydraulics to servo-hydraulics, or a “hybrid” system, can bring a substantial upgrade in machine capability. Speed control, force control, torque control, and other enhancements all come from upgrading to a servo system. Adding a servomotor to a pump to create a hybrid system can yield similar benefits.

The current generation of high-pressure variable displacement pumps from leading manufacturers provide critical performance advantages and can be easily configured to replace older press pumps. This generation of pumps has been proven to operate virtually trouble free for over 60,000 hours in extrusion applications. Productivity increases greater than 10% have been demonstrated under real production conditions, and they have been designed to operate with low noise to improve operating environment conditions.

In addition, high-speed variable displacement pumps, such as Bosch Rexroth’s AA4VSO system, provide short control response times and excellent suction characteristics, enabling increased parts production while reducing energy requirements.

Retrofitting an older machine can add a decade or more to its service life.

Real-time data and analytics can transform press control. A key factor in production efficiency is minimizing unnecessary downtime, thus increasing overall usage. Implementing analytics is vital to understanding what is going on with machines in production. Several leading press technology providers now offer online digital condition monitoring systems that more effectively support predictive maintenance on large industrial equipment.

Today’s electrohydraulic pump and control technologies now offer self-diagnostic and connectivity capabilities that can help manufacturers implement true Industry 4.0 capabilities in press operations. By adding sensors to key functional components and connecting back to simple hardware with a web-based interface, it’s possible to gain real value from data you didn’t think you could get.

With real-time data, operators have instant visibility to equipment problems or deviations. Sensors can be calibrated to monitor machine part wear or temperature and keep operators informed on individual press operations and other key production processes.

With increased transparency of the system’s status, there is more assurance that the machine is being properly maintained and operated. In the connected world of Industry 4.0, actionable data can drive lean manufacturing and continuous improvement efforts. Integrated sensors can even predict production issues before they occur and alert machine operators to take action before production is affected.

Modular ‘drop-in’ retrofit solutions deliver results fast. One concern that many press operators have about retrofits is the cost and disruption they assume automatically comes with retrofits. After all, when a press isn’t producing parts, no one is making money. It can take a week or more to remove old piping, valves, fluid reservoirs, and pumps, then integrate new pumps with digital controls into the press’s controls platform, then test and bring the press back online. Some press operators prefer to just keep doing the repairs and kick the retrofit plans down the road.

In the past, this concern might have been legitimate. However, leading electrohydraulic controls and pump providers like Bosch Rexroth have developed modular, turnkey replacement programs that can remove a legacy pump and control valves and complete the replacement in a weekend – in some cases, in just one shift. These drop-in solutions feature a unique system to directly replace the old, expensive, and inefficient pumps by designing and engineering a pump/manifold/controls solution.

With rapid advances in connectivity and performance in both electromechanical and hydraulic systems, press operators should consider upgrading presses via retrofit. Optimized machine functionality and additional safety features can increase throughput and press productivity. In fact, hydraulics upgrades using the modular drop-in solution often demonstrate productivity increases exceeding 10%.

Adding improved sensors and digital controls can quickly convert a decades-old workhorse press into a cutting-edge, Industry 4.0 system that is more energy-efficient and equipped to deliver many more years of high-quality parts production. •