Riding the Rails: Pneumatics Is Essential to Train Travel

By Frank Gevers, Director, Railway, Fluid Control and Pneumatics at Emerson

From air preparation to operation and passenger experience, pneumatic products are found throughout passenger and freight trains. Pneumatics is used for everything from brake control, suspension, and leveling, to air conditioning and toilet control.

Rail car manufacturers use pneumatic products for these applications because they’re reliable, durable, cost-effective, and provide benefits that go beyond their high performance. In addition to improving the operation and passenger experience, selecting the right pneumatic products can significantly extend maintenance intervals and minimize downtime while reducing maintenance costs and energy consumption.

Reliable air preparation

Whether freight or passenger, railway pneumatics begins with a reliable, dry air supply. Moisture can wash out grease and cause corrosion or lead to ice buildup at low temperatures. This can disable door systems or, even worse, freeze valves in the brake control circuit, all of which results in trains being taken out of service.

Most air dryers use a granular adsorption medium. Unfortunately, the shock and vibration from rail operations can cause channeling, air bypass, and dust generation or even lead to a breakdown of the granulate bed and a significant reduction in drying performance. This results in a shorter service life, requiring more frequent replacement of the adsorption medium.

The typical service interval for air dryers is less than two years. However, new developments in drying technology can extend that service life and reduce maintenance costs while increasing performance. For example, Emerson’s AVENTICS RDD air dryer series uses rolled-up desiccant drying technology that provides a consistent, highly open porous structure throughout the media, resulting in superior moisture uptake performance. Resistant to vibration and excessive water loading, the air dryer works in both horizontal and vertical orientations for more installation flexibility. Furthermore, it provides a service interval of at least eight years (or greater than 25,000 operating hours) instead of two years.

The design is based on two columns containing the drying medium inside easy-to-replace cartridges, where one column is always drying the air and the second one is being regenerated by purge air. Once one column is saturated and must be regenerated, control valves switch the air supply between the two columns automatically. The high moisture uptake and improved kinematics reduce the purge loss compared to conventional air dryer technology (less than 15%), leading to less air consumption and more energy savings.

Train operation

In both passenger and freight train operation, safety comes first. The technology used to control leveling and brake control, chassis suspension, and pantograph control needs to be extremely reliable and durable enough to withstand rugged environmental conditions and extreme temperature ranges. Components must be easy to maintain and need to have a long life cycle. Intelligent, durable, and low-maintenance pneumatic components are ideal here for fulfilling a wide range of applications on trains.

Brake control and actuation. The use of air for braking on trains originated in the mid-1800s. More than 150 years later, pneumatics is still the best technology to use for brake control; it’s easy to maintain, exceptionally reliable, and intrinsically safe.

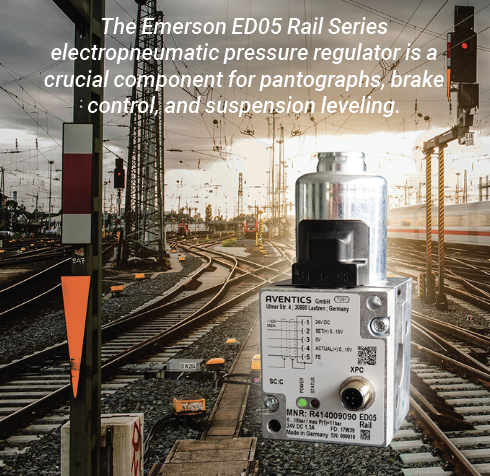

One of the latest key components in a railway brake system is the electropneumatic (EP) pressure regulator, which provides precise control of pressure and flow with dynamic regulation – especially important for brake control.

In Emerson’s ED05 Rail Series EP pressure regulator, the direct electromagnetic actuation of the integrated poppet valve allows for precise true proportional control with a high flow rate and combines dynamics, precision, and excellent repeatability with extreme durability. It provides robust poppet valve technology that does not require any special air quality. A large cross section and a soft-sealing proportional valve seat make the valve durable and resistant to contamination.

Some suppliers like Emerson also make it easy to order the complete pneumatic brake control unit. All the required components, including safety valves, pressure switches, ball valves, and pressure sensors, are preassembled and tested on a ready-to-install control manifold for the service, emergency, and spring-loaded brake functions on a train.

Chassis suspension and leveling. Besides braking systems, pneumatics plays a key role in chassis suspension systems, such as the pneumatic control of air springs. An electronic leveling valve provides significant benefits over conventional manual leveling valves. It primarily consists of one proportional valve, two switching valves, and control electronics with sensors. The bus interface makes controlling easy and allows for life-condition monitoring. Control electronics optimize the control and switching behavior of the integrated valves while minimizing air consumption.

It can be advantageous to partner with a supplier that can customize hardware and software to exact application requirements. These customized, ready-to-install assemblies deliver benefits over discrete components that must be assembled and adjusted separately. In one example, a manufacturer designing train cars for the bustling London passenger rail system needed a faster alternative to complex and often time-consuming mechanical air suspension. Emerson customized an electronic leveling valve that not only adjusts the train height to the platform level more quickly, it significantly decreases train air consumption and lowers operating costs.

Pantograph control and actuation. On electrically powered trains, when it comes to pantograph control and actuation, there’s absolutely no room for compromise. Pantographs must work in all conditions at any speed. The primary challenge is to constantly maintain the contact between the catenary cable and the pantograph’s carbon strip without pressing against overhead lines too forcefully, otherwise they will rapidly wear or even rip. Pneumatic control solutions provide the dynamic performance this precise application requires. Compared with electromechanical solutions, quality pneumatic solutions are virtually wear-free.

Emerson, for instance, supplies a preassembled pneumatic assembly for pantographs to a Swiss company that has made pantographs for over 100 years. The pneumatic control solution, which consists of a valve, precision pressure regulator, pneumatic bellow actuator, and air preparation, presses the pantograph’s carbon strip against the overhead line with just enough pneumatic force to maintain contact, even when tracks are uneven. These particular pantographs are approved for speeds up to approximately 143 mph (230 kph), proving just how effective the assemblies and pneumatic solutions truly are. In addition, further developments involving EP pressure regulators have proven their performance up to speeds of approximately 217 mph (350 kph).

Passenger experience

From the moment passengers enter the train to the moment they exit, a range of pneumatic components ensure their experience is as safe and comfortable as possible.

Starting at the train door, rodless pneumatic cylinders provide reliable actuation. And for those trains that need a step to board quickly and safely, sensor-controlled cylinders in the sliding step provide exact extension and retraction to ensure the step precisely lines up with the platform.

Once passengers are in their seats, pneumatic components actuate and control HVAC systems, keeping the ride comfortable. Pneumatic components that instantly close the fresh-air intake help protect passengers from pressure changes when high-speed trains encounter oncoming trains or enter and exit tunnels. If the fresh-air intake is not properly and quickly closed, pressure waves can enter passenger cabins.

If passengers must leave their seat during the journey for a restroom break, Emerson’s electromagnetic valves ensure a proper functioning toilet. The valves are used to control several different functions that help provide a comfortable experience every time.

Railway standards

No matter how well pneumatic components function, it is equally important that they meet current railway-specific standards and requirements. These include ratings for electromagnetic compatibility (EN 50121-3-2), corrosion resistance, fire protection (EN 45545), shock and vibration (EN 61373), temperature, and more. It’s crucial to work with an expert supplier who knows the industry and offers support and products that comply with the latest global standards – for individual components or complete plug-and-play subsystems.

From braking to actuators, airflow, and control, pneumatics can do it all. Whether a solution is needed for new trains or a refurbishment project, pneumatics designed specifically for the rail industry helps ensure all specifications can be met successfully.