Schmalz Releases New Compact Ejectors

The new Schmalz SCPM mini compact ejectors are designed to handle airtight workpieces such as display glass, plastic parts, printed circuit boards, electronic parts, and batteries. They are ideal for applications with highly dynamic pick-and-place movements and extremely short cycle times, such as SMD machines with a small footprint.

The new Schmalz SCPM mini compact ejectors are designed to handle airtight workpieces such as display glass, plastic parts, printed circuit boards, electronic parts, and batteries. They are ideal for applications with highly dynamic pick-and-place movements and extremely short cycle times, such as SMD machines with a small footprint.

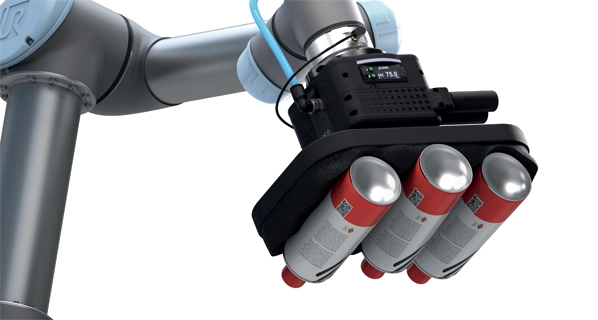

The ejectors also work on robotic handling applications and on linear axes positioned as close to the suction pads as possible. They are commonly used in fully automatic handling applications with downtime requirements, where downtime stats are obtained through intelligent condition monitoring.

SCPMb / SCPMc / SCPMi ejectors may be used in combination with an external vacuum supply, and they are also available in a terminal version for controlling up to 16 different vacuum circuits.

Other highlights of the ejectors include optimized power-to-size ratio, streamlined and robust system design, and an option for pneumatic block mounting with up to 16 ejectors.

The ejector promises maximum suction capacity in the smallest possible space, low interference contour when installed, central air supply, and various independent vacuum circuits.