Seal-Glide Reduces Friction with Nanoscale Surface Treatments

Trelleborg recently released Seal-Glide, a specially formulated surface treatment to improve assembly processes and application performance by virtually eliminating friction and sticking.

Trelleborg recently released Seal-Glide, a specially formulated surface treatment to improve assembly processes and application performance by virtually eliminating friction and sticking.

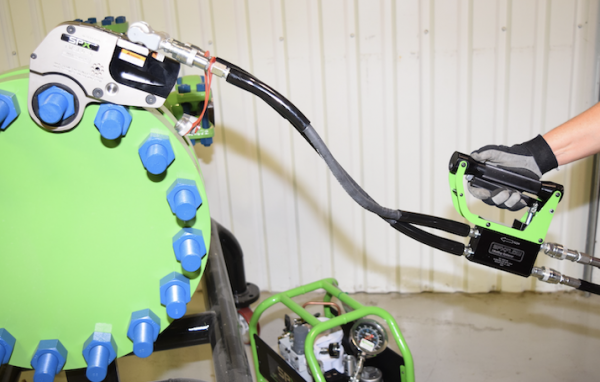

Now joining the ServicePLUS family, Seal-Glide is a nanoscale surface treatment that improves on the friction performance of conventional coatings. It is applied through an innovative process, leading to a finish up to 50 times thinner than many conventional coatings. This technique also enables treatment of components with complex geometries and features, such as undercuts, that would otherwise be impossible with lacquer-based coatings. Even after being stretched, Seal-Glide returns to a smooth finish with no breakouts, maintaining its improved sliding properties.

Testing has shown that the initial coefficient of friction on application start-up can be reduced by more than 80%, easing assembly and stick-slip effects during operation. During dynamic operation, Seal-Glide shows significant friction performance improvements. Due to its excellent adhesion and low abrasion, the friction is also lower for longer when compared with standard surface modifications.

Compatibility with a wide range of materials and flexibility with regards to part geometry means that Seal-Glide can be used in many different applications and industrial segments. To take advantage of its friction reducing potential for the health care and medical industries, Seal-Glide Medical offers the same benefits with additional approvals and adherence to regional and global regulations.

For more information, visit www.tss.trelleborg.com/en.