The Do’s & Don’ts of High-Pressure Hose Care and Use

By Jerry Carter, Vice President of Sales and Chief Compliance Officer, Spir Star.

While this article is rooted in the use of ultra-high pressure thermoplastic hose, the overall concept of hose care and use can be applied to the use of hose in any industrial environment. Regardless of application, all hose is used to move material from one place to another in a contained manner, and usually under some form of internal pressure. The variables can be size, materials of construction, and working pressure. It may seem basic, but it is important to note that hose, unlike some other forms of materials transportation such as rigid pipe, is a flexible component by design, manufactured from materials to achieve flexibility and pressure containment. Hose takes more abuse than a more stationary product. Additionally, what separates low, medium, and high pressure is somewhat subjective depending on the industry in which you work. For example, a water blast contractor may consider a high-pressure hose to be somewhere between 10,000 and 60,000 psi whereas someone using standard rubber hydraulic hose may consider 3,000 psi to be high pressure. While there is an obvious difference in the two examples in regard to pressure capabilities, both can be dangerous if not selected, handled, and maintained properly.

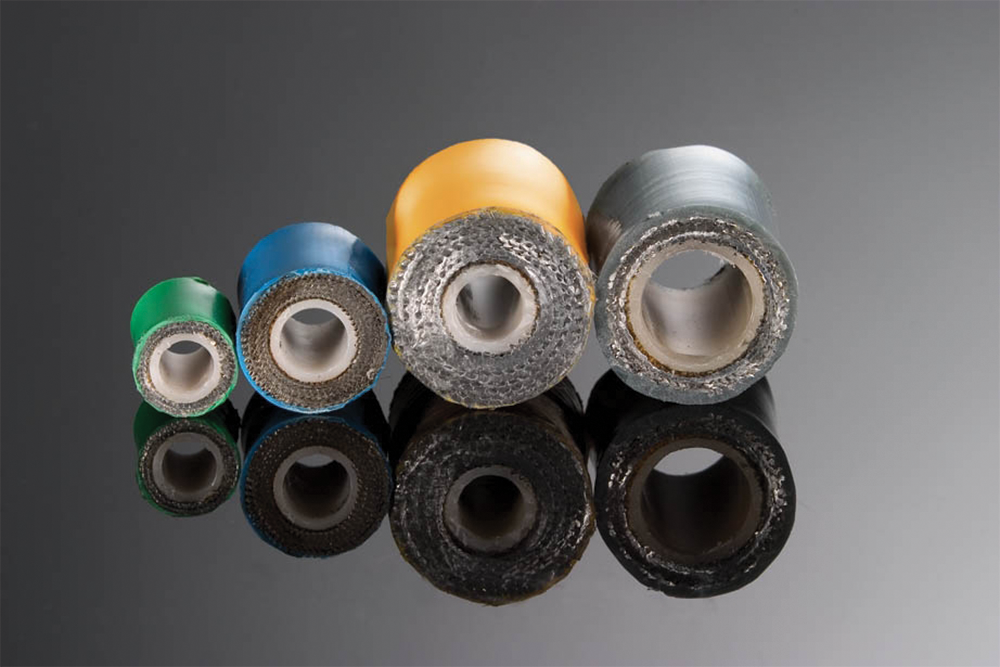

To understand how to work safely with hose, it is good to have a basic understanding of what makes up a hose assembly. The majority of hose assemblies will be made up of four components: an inner core, which is the internal portion of the hose that carries the media and contains pressure when applicable; an inner core reinforcement such as spiralized or braided wire, or textile materials that support the inner core; the outer cover of the hose which protects the inner core and support materials; and finally, the end fitting connections used on the hose which vary depending on the hose type and application. Materials and methods of construction can vary greatly depending on the design and use requirements of the hose including consideration of the medium flowing through it. However, the basic component concept of construction is generally the same and beneficial to understand when working with hose products.

In any industrial application where hose is being used, hose care and use safety should be a priority for those handling or working near the hose assemblies. It is important to remember that if a hose is being used, it is being used to transfer some form of media, which could be hazardous, it could be high temperature, and it could be under considerable internal pressure. High pressure hydraulic hoses in particular can offer extreme flexibility and low weight to withstand the demands of applications like autofrettage, hydroforming, hydraulic assembly presses, dismantling of ball bearings and torque and bolt-tensioning tools. You’ll find high pressure hydraulic hoses in factories, refineries, vehicle manufacturing, commercial farming, in construction and many other forms of manufacturing. When required, this is where using thermoplastic high-pressure hose can be preferable because they are extremely durable, lightweight, and very flexible. A small bend radius at maximum flow may be better achieved with a quality thermoplastic hose.

Carelessness or misuse can lead to serious injuries. It should be noted that the performance of the hose once in the field and the hose life is directly affected by the environment in which it is being used, the treatment of the hose while it’s being used, and the cleaning and storage (if applicable) of the hose after use. The Do’s and Don’ts of Hose Care and Use stated here are basic guidelines that can be incorporated to work in a safe manner, helping to protect property and personnel.

Do’s

- Always use extreme caution when working with hose. Remember, it is a pressure vessel and should be treated as such.

- Visually inspect hose assemblies prior to use and remove any hose assembly that could be a hazard. Visual inspection should include inspecting for damage to the hose outer cover as well as damage or corrosion to the assembly end fitting connections.

- Know the capabilities and specifications of the hose assembly you are using in terms of media compatibility.

- Always know the manufacturers recommended working pressure of the hose assembly.

- Know the type and maximum working pressure of the end fitting connections of the hose assembly as well as any accessories such as adapters, quick disconnects, etc.

- When possible, drain and flush hose assemblies after use.

- Always wear proper protective equipment when working with hose.

Don’ts

- Never handle a leaking hose assembly while under pressure.

- Don’t use a hose assembly with damaged and/or corroded end fitting connections.

- Hose assemblies with kinks, significant abrasions, and visible damage should not be used.

- Don’t put hose assemblies in the path of vehicles or equipment. If a hose assembly is run over, it should immediately be taken from service.

- Hose assemblies should not be hung from structures in a manner that the assembly end fitting is supporting the weight of the hose assembly.

- Don’t exceed the manufacturers recommended bend radius of a hose.

- Never exceed the manufacturers recommended working pressure of a hose assembly during use.

A key factor in hose safety is to not assume that hose of any type will last forever. A high-pressure hose, like a pressure vessel, holds high pressure; it is not a garden hose. By the nature of the application, hose assemblies can see considerable wear and abuse. But, perhaps the most common cause of hose failure is using any part of the assembly in an application for which it is not designed. Quality hose manufacturers recognize that testing and certifying at the time of hose assembly manufacture and periodically recertifying your hose assembly is the gold standard of hose safety and should be implemented in the internal asset management of an organization that uses hose products. These companies advocate for safe handling practices to prolong hose life and human life. By implementing guidelines, including those given here concerning hose care and use in applicable situations we can educate personnel on how to work safer, ultimately benefiting all involved.

Can I use a lance when the hose is fully wound around the reel or should unwind the full hose before using the lance?

Thank you