The Wow Factor: Hydraulic Cylinders in Entertainment

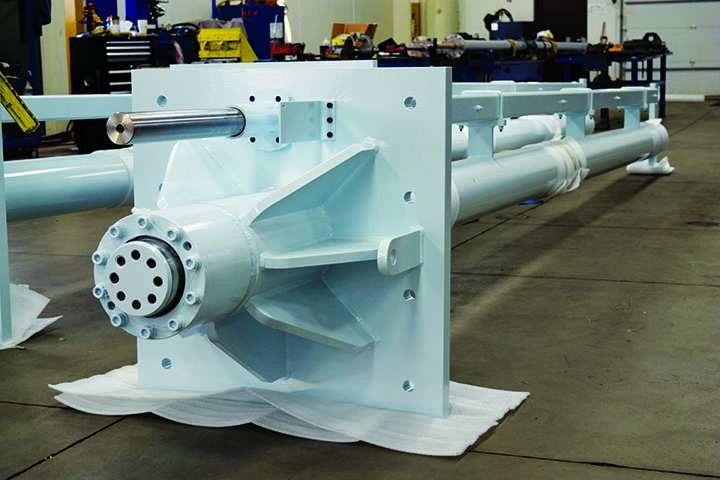

Hydraulic cylinder for an underwater stage.

By Tony Casassa, Engineering Manager, Aggressive Hydraulics

When thinking about hydraulic cylinders, typically the first applications that come to mind are construction equipment like excavators and dump trucks or industrial applications like presses. However, a relatively unknown hydraulic application is entertainment. Except for fluid power enthusiasts, most people would not buy a ticket simply to watch a hydraulic cylinder extend and retract. However, hydraulic cylinders work behind the scenes to provide linear motion for amusement parks, animatronics, live shows, and other entertainment venues. These cylinders have much in common with their more utilitarian cousins, but they often have unique features to meet the requirements of the entertainment industry.

One common requirement is the need for reliability. If the hydraulic cylinder on a dump truck fails, the owner of the dump truck loses revenue during the time the truck is inoperable and not hauling loads. In the same way, if an entertainment venue must cancel a show because of cylinder failure, there is a loss of revenue from ticket sales. So cylinders for entertainment must be designed for a high level of reliability because, as the old saying goes, “the show must go on!” Welded-type cylinders provide a high level of integrity through numerous pressure cycles, even in high-vibration environments. They can also be easily disassembled to replace the seals or perform other service work, a task that is even simpler with bolted head glands.

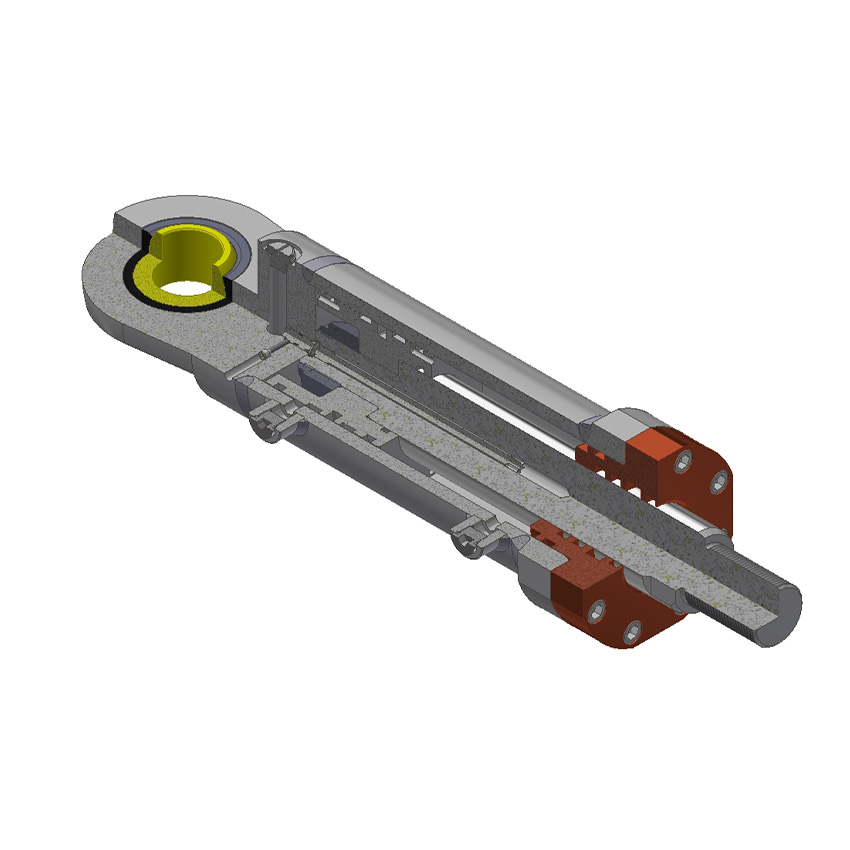

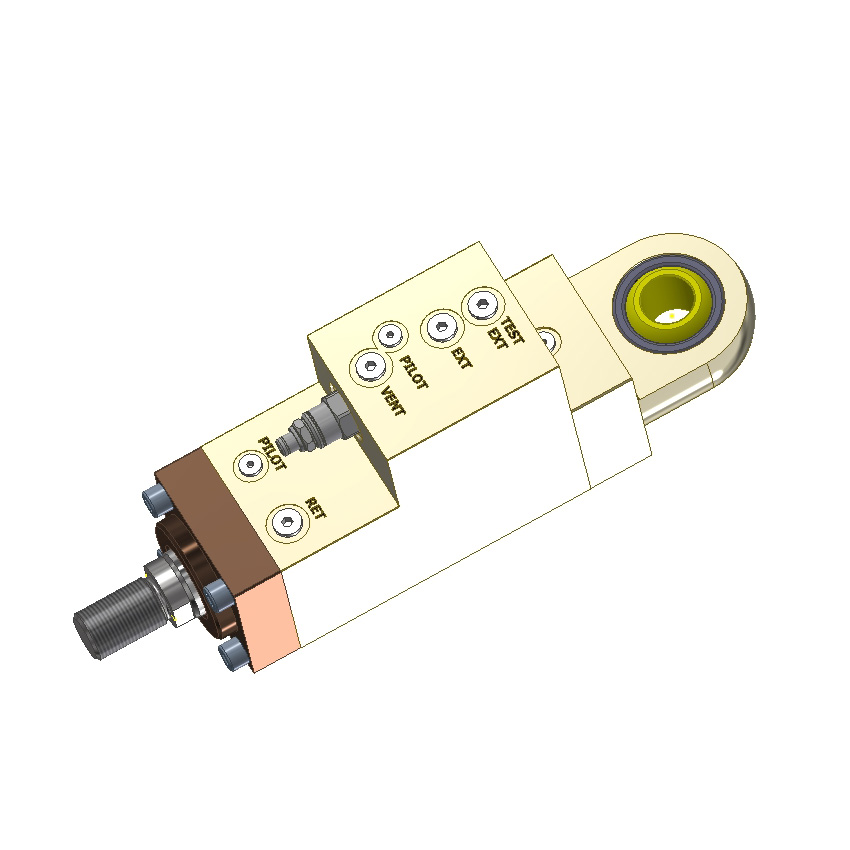

Animatronics cylinder engineered by Aggressive Hydraulics.

One specific area of reliability is the rod sealing system. Although rod-seal leaks are never desirable, some users of mobile and industrial equipment tolerate a certain amount of leakage on a machine that may already be greasy or dirty. At an entertainment venue, cleanliness has a high level of importance to the patrons and, by extension, the owner. So there is little tolerance for unsightly leaks that may form a puddle on the ground, create an oil slick on the water, or become a collection point for dust and debris. The cylinder must be designed with highly efficient seals that endure many cycles and wipe the rod clean before it extends. The rod wiper must keep out contamination that may damage the rod seal. In some cases, a buffer seal may be added to dampen any pressure spikes from reaching the main rod seal, extending seal life. A leak detection port may be added to indicate if the rod seal has been compromised. This port could be used for a visual sight gauge, electrical pressure switch, or drain tube to a holding reservoir. Any of these methods can be used to alert maintenance personnel when it is necessary to schedule repair downtime. The leak detection port is especially valuable when the cylinder is used in or around water.

Challenges presented by water

Seventy-two percent of the earth is covered by water, and water is also a common feature in the entertainment world. From fountains to water features on rides to wave pools, H2O is ubiquitous because people find water fascinating. Water poses two primary threats to hydraulic cylinders: corrosion and water ingression. Carbon steel or ductile iron, common raw materials for cylinder components, are prone to rust in the presence of water. This rust is not only unsightly, over time it weakens the material and can result in failure. Fortunately, there are solutions to combat this problem. For the barrel or body of the cylinder, corrosion can be slowed by special paint finishes, for example, inorganic zinc primers or two-part marine-grade epoxy. If that is not adequate, nickel plating the exterior components provides an even more robust barrier than paint. Although typically not viable on large cylinders due to cost and material availability, smaller cylinders can be manufactured from stainless steel and bronze to inhibit corrosion.

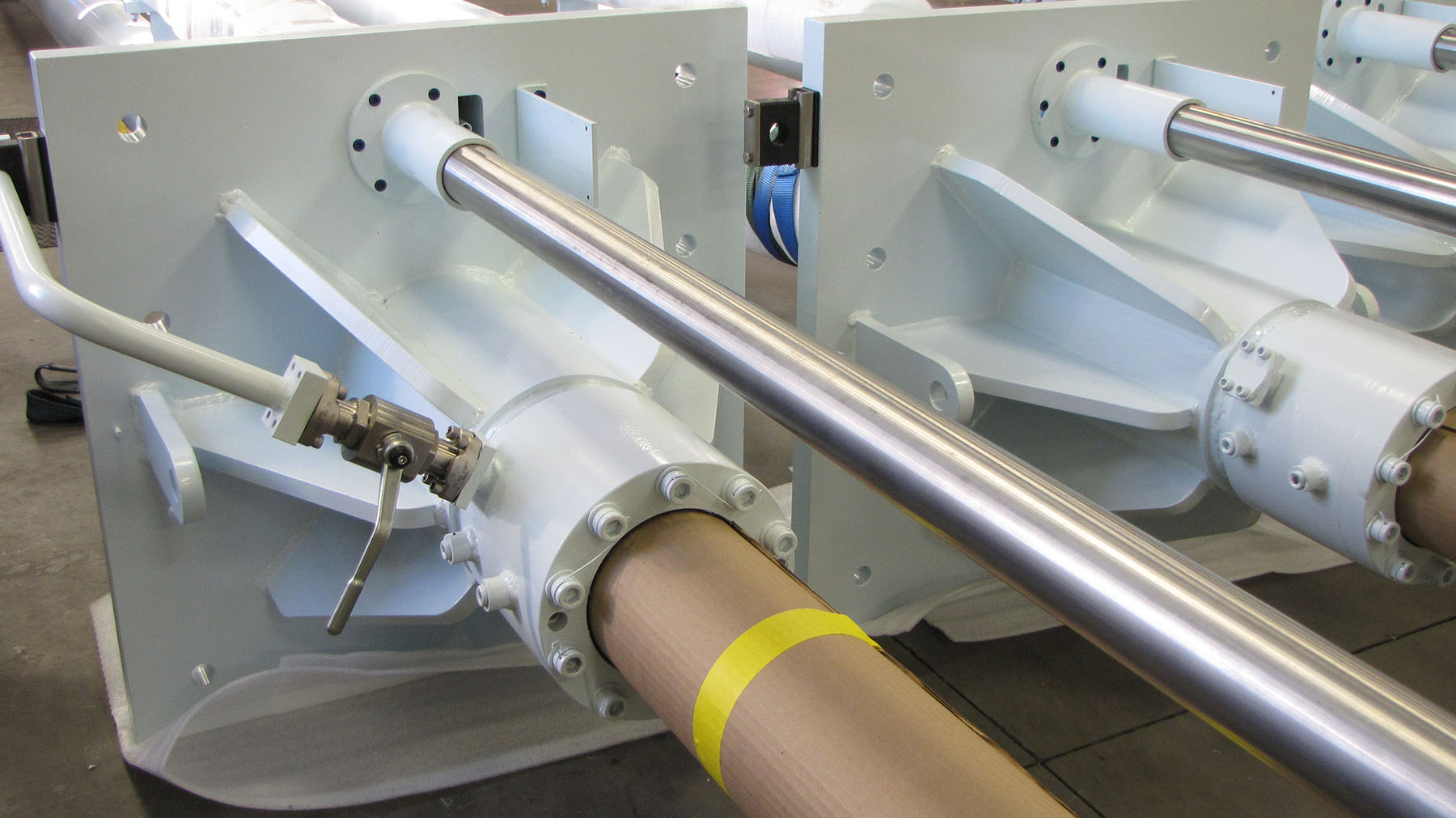

Closeup of the hydraulic cylinder developed for an underwater stage.

The cylinder rod, which is typically chrome-plated carbon steel, presents a unique challenge for corrosion protection. Chrome is a hard surface that is compatible with the rod seals, and chrome also provides a limited amount of corrosion protection. Chrome itself is resistant to rust, but it has microscopic cracks that let moisture penetrate to the base material, allowing it to rust and lift off the chrome plating. The options for the cylinder case are not viable for the rod; paint would strip off when the rod cycles, and nickel plating is too soft. There are viable solutions, including chrome application methods that significantly reduce the microcracks and form a stronger barrier to protect the base material. A different option is to plate the rod with a layer of nickel plating below the chrome, as the nickel provides corrosion resistance, and the chrome provides a smooth, hard surface for the seals. Instead of trying to protect the base material, yet another strategy is chrome-plated stainless steel, in which the chrome only provides the surface for the seals and the base material is resistant to corrosion. Although 300-series stainless steel provides more corrosion resistance, 17-4 stainless is typically used for the combination of good corrosion resistance and high tensile strength. The drawback of stainless steel, whether for the barrel or the rod, is higher cost and lower material availability, especially in larger diameters.

Corrosion is not water’s only threat to hydraulic cylinders, which are typically designed only with seals to keep in the high-pressure fluid. If the cylinder is submerged or splashed, water can find a way inside the cylinder and mix with the hydraulic fluid. This contamination can result in fluid breakdown and internal rust of the cylinder and other hydraulic system components. Special seal configurations prevent this water ingression. An additional rod seal turned outboard to seal against the rod can prevent water from entering the rod gland. Because the seal material typically used for hydraulic fluid often swells or softens when exposed to water, the outboard seal should be a compound compatible with water.

Protecting electrical sensors

Rendering of an animatronics cylinder.

Watery environments can also pose a threat to the linear position sensors that are often integrated in cylinders. There has been a significant trend in all types of machines and equipment to add electrical sensors and controllers, and hydraulic cylinders for entertainment reflect the same trend. One application is multiple cylinders working together to raise and lower an underwater stage. An integral linear position sensor can enable synchronization of the cylinders and provide an alarm notification if the stage is out of position. Although current standard sensor offerings have reasonable water ingression protection for most environments, severe or submerged applications require nonstandard configurations. In the example of the underwater stage, the sensor is protected by a custom-designed sealed enclosure with a cord grip for the terminating cable. In another example, that of animatronics cylinders that bring full-sized characters to life, specialized connectors designed for subsea environments are used to maintain electrical reliability. The job of these connectors is to transmit the output signal from the sensor integrated in the cylinder. Sometimes these outputs are common analog or digital outputs, but other cases require unique outputs. Often the controllers are highly specialized, as they go beyond typical motion control and also manage lighting and sound for the ride or show. They may require special sensor outputs like PWM – pulse width modulated. In other cases, the system may have been designed years ago with a specific type of resistive sensor that is no longer available. Because of the cost and the high level of integration, changing the electronic controller is not a viable solution. So a replacement cylinder must be designed with a sensor to provide the same feedback. This level of customization is not limited to the sensor.

Hydraulic cylinders range from standard off-the-shelf products to catalog options and highly customized types. In the case of an off-the-shelf cylinder, the customer must design the machine around the standard product or modify as needed. Catalog cylinders provide more options but are still limited to the predetermined configurations offered by the manufacturer. Custom-welded cylinders provide a high level of design flexibility, which is very important in many entertainment applications that require unique solutions. One example is a cylinder to generate waves in a pool at a water park. The duty cycle demand is high, as the cylinder operates continuously every day from open to close, and the tolerance for leakage of oil into the pool water is low. Therefore, the cylinder is designed to prevent fatigue failure and includes a dual seal and leak-detection port configuration. Although not submerged, the proximity to water requires corrosion protection features, including chrome-plated stainless steel rod, epoxy paint, and salt bath nitride head gland.

The next time you visit an amusement park, live show, or even a sports event, keep your eye out for hydraulic cylinders at work behind the scenes to entertain the audience. •