What to Look for When Selecting Compact Air Cylinders

Exploring the configurations, sizes and internal components that can make or break cylinders in short-stroke applications

Exploring the configurations, sizes and internal components that can make or break cylinders in short-stroke applications

By Troy Sanders, National Sales Manager, Fabco-Air Inc

Compact air cylinders are critical to a wide range of applications, including printing, palletizing, robotics, automotive assembly, semiconductor processing, and more. This type of pneumatic actuator provides short strokes in a compact, low-profile design, enabling you to use it in very tight spaces. With bore sizes from 0.5 inches to 4 inches and a maximum standard stroke of 4 inches, these cylinders typically feature the longest possible stroke for the smallest package size.

In light of their value and widespread use, it’s important to remember that not all compact air cylinders are created equal. There are a number of products currently competing for your attention and a share of the actuator market. Many of these components have similar features. Some even look alike, featuring the exact same exterior dimensions. How, then, can you decide which cylinder to use?

This article provides a helpful overview of air cylinder design and also explores the key features you should look for when selecting a compact cylinder for your application.

Compact air cylinder styles and configurations

To specify the right air actuator, it’s helpful to ask yourself two main questions. The first is: What type of work does the cylinder have to perform? The second is: What types of cylinders do you have to choose from?

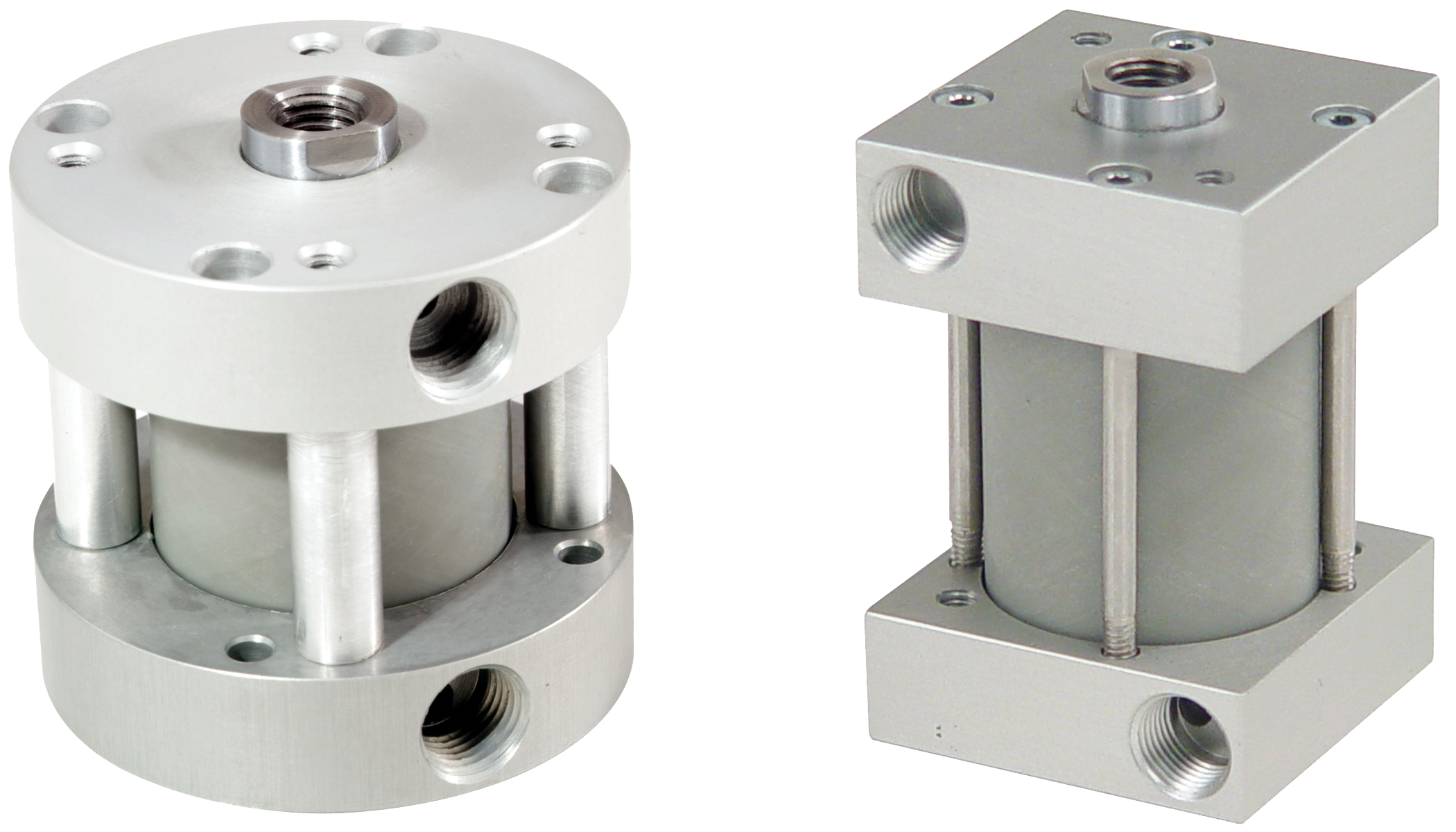

Compact air cylinders typically come in a wide range of styles, sizes, and mounting options (see sidebar). They can be double acting, which is ideal for pushing and pulling tasks like feeding, lifting, lowering, and sorting. They can also be single acting – an ideal configuration if your application requires force in only one direction or involves unloaded return strokes. For safety reasons, single acting cylinders are also popular if a defined position must be taken in the event of a power failure. Typical tasks for this style include clamping, ejecting, and actuating flaps and levers.

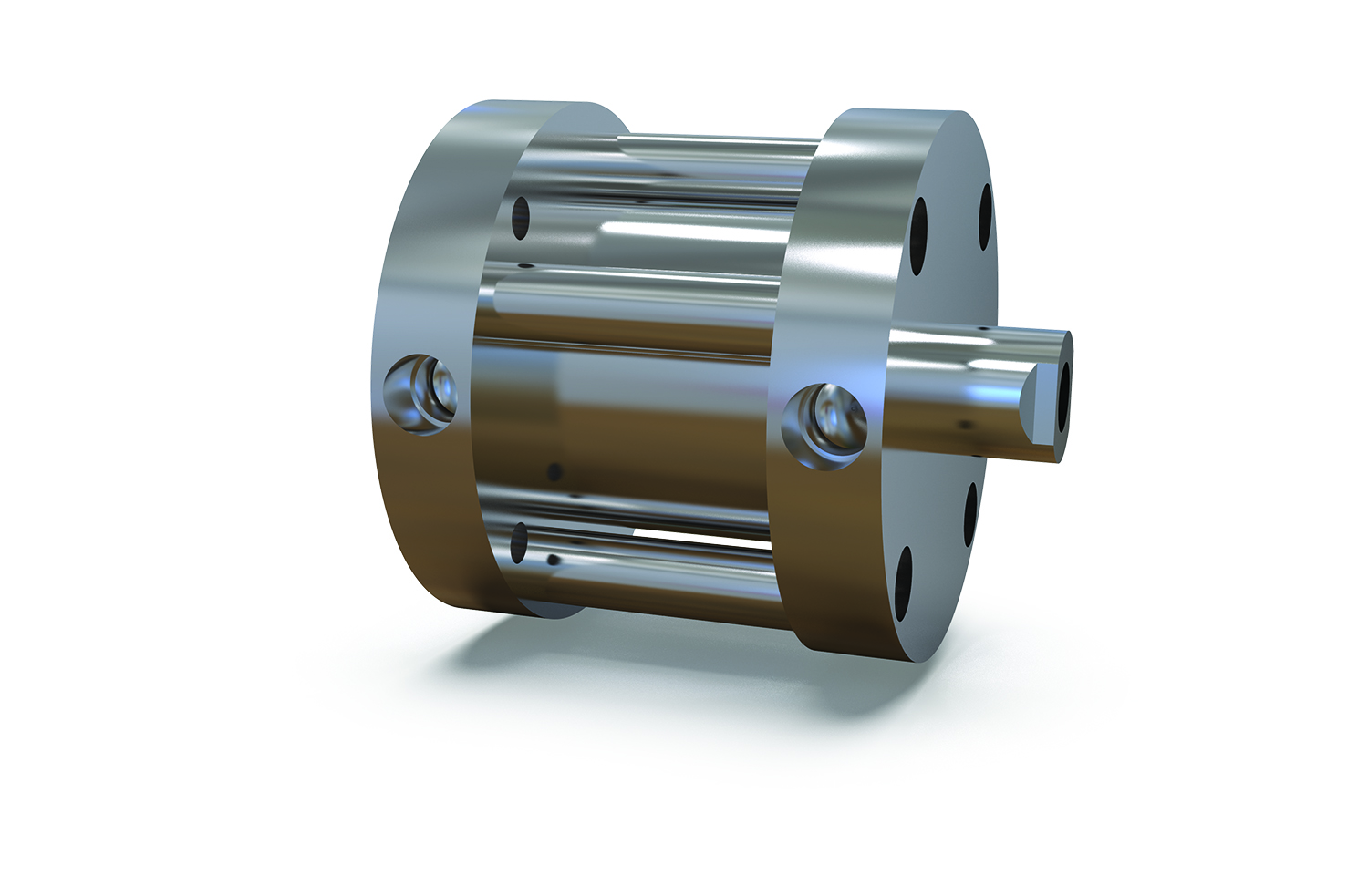

Compact air cylinders also come in single or double rod designs. A more common option, single rod designs often include a spring that extends or retracts the rod. Double rod cylinders, on the other hand, are useful whenever you need equal displacement on both sides of the piston. You can also use the extra end to mount cams for operating limit switches.

In addition to specifying the right configuration, it’s important to make sure your compact air cylinder meets the proper size requirements. Due to their use in tight or limited spaces, look for standard bore sizes between 0.5 inches and 4 inches, as well as standard strokes up to 4 inches.

In addition to a bored body design, Pancake cylinders are available with round and square designs (left and right) in a conventional tie-rod/spacer configuration.

Nonmetallic composite walls deliver strength

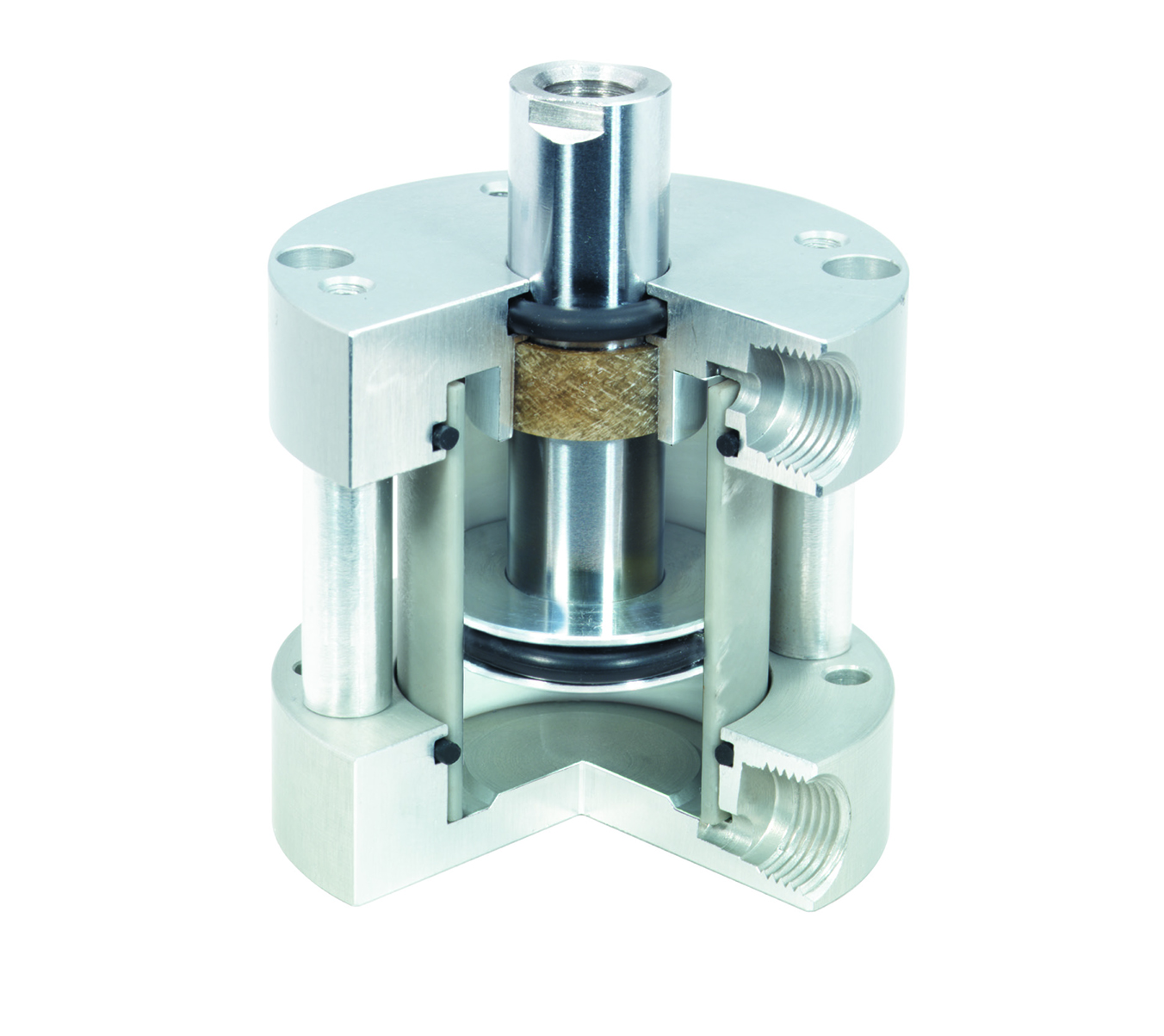

To truly evaluate a compact air cylinder, it’s helpful to take a look at what’s inside. High-performing cylinders will integrate top-of-the-line internal components. Fabco’s Pancake cylinders, for example, incorporate stainless steel tie bolts and aluminum spacers, which lock precision-machined heads tightly around a strong composite cylinder barrel. This type of nonmetallic barrel features a smooth, self-lubricating interior surface that ensures reliable, long-lasting performance. At the same time, its high impact resistance reduces the chances that the cylinder will fail due to damage. By contrast, many compact air cylinders currently on the market integrate stainless steel cylinder walls, which, unlike nonmetallic composites, are subject to dings, dents, and other damage. Many also include mirror-finished bores, which make lubrication difficult. Due to their zero slipstick design, Pancake cylinders also avoid the stiction problems metal cylinders encounter when they sit in a static position for too long. Combined with hard, chrome-plated stainless steel piston rods, as well as a nonmetallic rod bearing, Pancake cylinders achieve optimal operation and service life.

Durable rod bushings improve service life

The better the bearing, the more cycles you can expect from your air cylinder. Look for compact cylinders with superior rod-bearing materials. Pancake cylinders, for example, incorporate a fluoropolymer-based composite that is bonded to a supporting lament-wound fiberglass and epoxy resin shell. This material resists corrosion, moisture and temperatures up to 325°F (163°C), enhancing the bearing’s load capacity and reliability in harsh environments. Many cylinders on the market feature oil-impregnated bronze bushings, which tend to pull out under side loads. These models also have a lower load capacity than composite options: 4,500 psi (310 bar) versus 60,000 psi (4,137 bar). In addition to composite cylinder walls and rod bushings, other important internal design features to look for in compact air cylinders include:

- Internally lubricated captive rod seals

- Internally lubricated piston seals

- Aluminum alloy spacers

- Stainless steel tie bolts

- Thick rear covers that prevent impact blowout

- Hard, chrome-plated stainless steel piston rods (8-12 RMS finish)

Compact air cylinders like the Pancake series play a critical role in a variety of applications, from conveyor systems to custom-built machinery. These high-performing cylinders come in a variety of styles and configurations. They also meet the right size requirements for use in tight or limited spaces. But most importantly, these cylinders incorporate high-quality internal components, enhancing your cylinder’s durability, reliability, and lifespan in short-stroke applications.

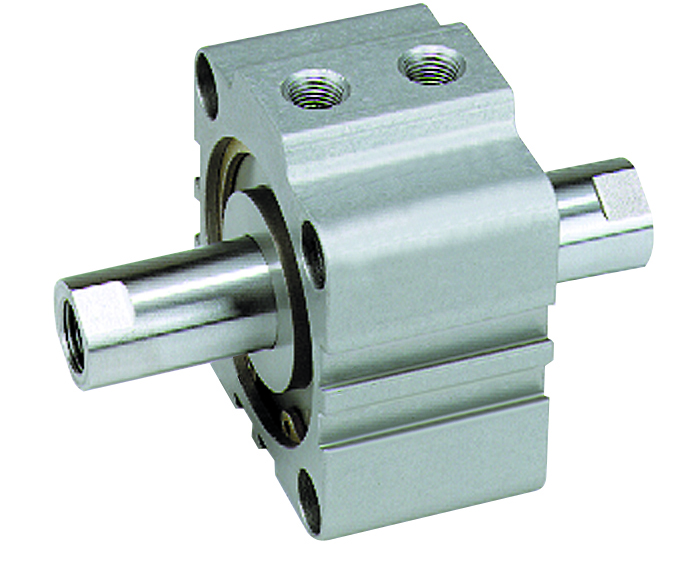

An overview of the key design features of a high-quality Pancake II cylinder.

Common Ways to Mount Your Air Cylinder Compact air cylinders come in a variety of mounting options: A double rod cylinder is useful whenever you need equal displacement on both sides of the piston.

Additional Options for Your Air Cylinder Cylinder bodies often include mounting grooves to mount and adjust electronic sensors.