Tsunami Releases New Dust Collector Regenerative Dryer

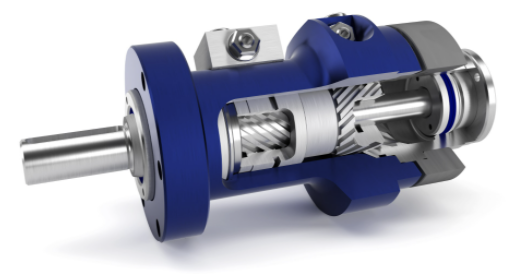

Tsunami Compressed Air Solutions has released a new dust collector regenerative dryer.

Tsunami Compressed Air Solutions has released a new dust collector regenerative dryer.

The robust drying system provides an all-in-one solution for dust collector systems designed to eliminate supercooling and supply ultra clean air to pulse valves. The dryers are proven to save plants up to 50% in air consumption and can increase bag (sock) life by up to three times.

Supercooling occurs during the rapid expansion of air that loses heat due to the immediate separation of molecules. For every 20°F that air cools, it loses approximately 50% of its ability to hold moisture in the form of vapor, or humidity. In collector applications, this cooling effect converts water vapor to liquid as air quickly expands out of each pulse valve. Damp air hits the bags or elements creating a wet cake substance that prematurely clogs the filter and inhibits air from passing through. Not only does this wet air reduce the life of each filter, it also wreaks havoc on collector systems in climates where freezing may occur.

By eliminating the moisture created during the supercooling process, bags on the dust collector regenerative dryer remain moisture free, allowing for proper vacuum and preventing premature reduction in differential pressure drop.

Tsunami dryers are built as complete packages and come ready to plumb directly in and out of the system.

For more information, visit www.gosuburban.com.