Tube Processing Machine Upgrades with Kyntronics Actuators

By Kyntronics

By Kyntronics

As modern automotive engineering for chassis systems evolves, manufacturers must retool to accommodate new model designs. The manufacturers are challenged to support existing parts while upgrading to produce new products.

A tier-1 automotive chassis-system manufacturer had to retool a hydroforming line to accommodate a new model design. The new line required the flexibility to produce both the current OEM product and the new product at higher volumes.

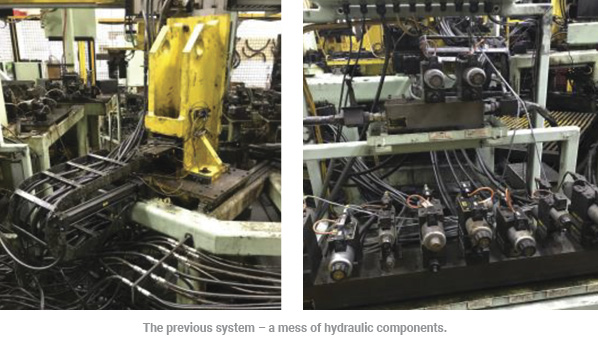

The manufacturer wanted to eliminate the messy and inefficient hydraulic system used in the old machine and implement new technology that provided better process control, was cleaner and quieter, saved energy, and had the flexibility to handle the part variability. The manufacturer’s hydroforming line had the additional challenges of eliminating a messy and inefficient hydraulic system while seamlessly integrating with Rockwell Automation controls and drives.

The manufacturer considered using electromechanical actuators but found that the large size and high cost of the technology would not meet project requirements.

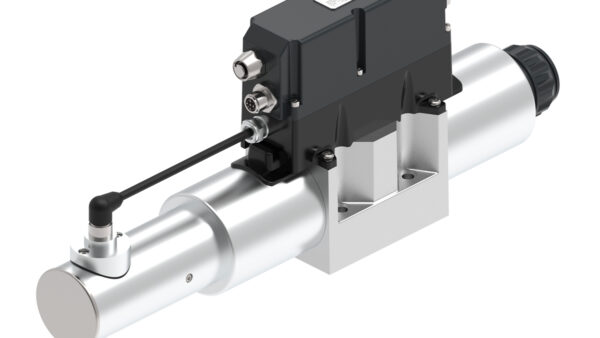

Working with a Kyntronics team, the manufacturer reviewed smart hydraulic actuators (SHAs). The SHAs were rated from 6,000 lbf (27kN) to 23,000 lbf (103kN) of force and provided both inline and right-angle configurations to optimally fit the available space envelope. The SHAs also incorporated Rockwell Automation Allen-Bradley servo motors and drives that met the customer’s control specifications.

The manufacturer selected 16 Kyntronics SHAs for the new hydroform tube processing machine. The SHAs exceeded the requirements of the machine builder and end customer in several ways.

The SHAs eliminated the space-consuming hydraulic power unit, manifolds, valves, and hoses, which resulted in a machine footprint 50% smaller than the previous production line. The ability of the SHAs to operate independently with cycle overlap allowed the new machine to produce 25% more parts per shift than the previous machine.

The programmability of the SHAs provided flexibility to handle multiple part variations with improved process control. Position and force control ensured optimal cycle times. Elimination of hydraulics on the new machine resulted in a cleaner, less noisy, and more energy-efficient environment.

The Kyntronics SHA combined the power of hydraulics with the precision of servo control and resulted in an ideal solution for the hydroform tube processing machine.

For more information, visit www.kyntronics.com/.