Understanding Break-Away, Running, & Starting Torque

A motor has a certain amount of mass that must be accelerated to the speed required to do the work. The object being moved also has some mass. The force to accelerate this mass is referred to as starting torque. There also may be some other resistance that must be overcome. This combination of starting torque and any additional restriction is referred to as break-away torque. For example, an auger moving feed to cattle must overcome its own mass and also the natural stiction of the feed. Once the motor gets up to speed, the resistance drops, and a lower torque is required to keep the load moving. This is running torque.

The stall torque is the maximum motor force, based on the pressure available and the displacement of the motor. It is the resistive force that will cause the motor to stop turning. The stall torque must be higher than the break-away torque but must be limited for the safe operation of the equipment and/or the limitations of the motor.

The stall torque is the maximum motor force, based on the pressure available and the displacement of the motor. It is the resistive force that will cause the motor to stop turning. The stall torque must be higher than the break-away torque but must be limited for the safe operation of the equipment and/or the limitations of the motor.

The geometry of most hydraulic motors is such that there are variations in torque as the motor rotates. This is called torque ripple. A 9 piston, high speed/low torque, axial piston motor will have 9 pulses of energy for every revolution. At 1,550 rpm, the pulses would be at 232 Hz and may have very little impact. A 6 lobe, low speed/high torque motor at 50 rpm will have a torque ripple of 5 Hz. At this low rpm, this torque ripple sometimes referred to as cogging, may influence process control.

When specifying a motor, it is important to include the maximum necessary starting torque as well as the running torque. If only the running torque is calculated, the motor may stall or be very slow in reaching the proper working velocity. When specifying a motor, it is important to include the maximum necessary break away torque as well as the running torque. If only the running torque is calculated, the motor may stall or be very slow in reaching the proper working speed.

For example, given an auger with a running torque of 400 Nm (3,540 lb-in) at 1,200 rpm, and an available pressure of 21 MPa (3,045 psi), a hydraulic motor must be chosen that can accelerate its own mass as well as overcome the stiction of the of the product being transferred. The manufacturer’s specifications say the motor will require an additional 10% pressure for start-up. The product stiction will require an additional 15% torque.

The required breakaway torque for this application is arrived at by multiplying the running torque required by the manufacturer’s data stating that 10% additional torque is necessary to overcome the inertia and mechanical friction internal to the motor which is the starting torque. This starting torque value of the motor is then multiplied by the additional amount of torque that is required to overcome the feed auger at rest which was given at 15%.

400 Nm (3,540 lb-in) × 110% × 115% or 506 Nm (4,478 lb-in)

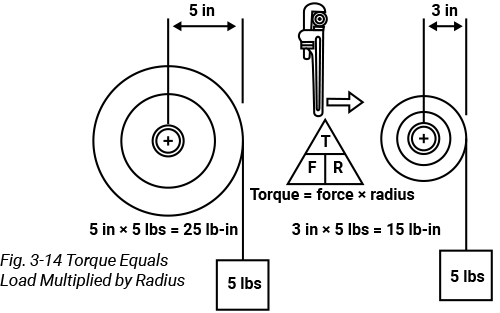

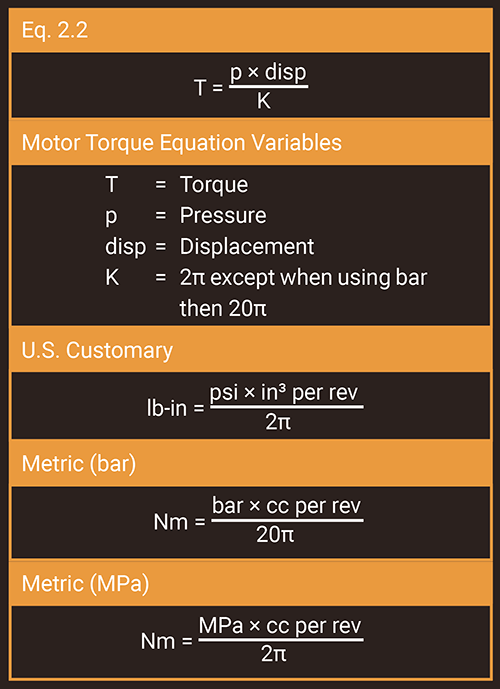

Using equation 2.2, the displacement of the motor required to perform the work at the given maximum pressure available can be calculated.

Test Your Skills

1. Comparing starting torque to running torque:

A. These are different terms for the same thing.

B. Starting torque is lower than running torque.

C. Starting torque is higher than running torque.

D. Starting torque does not need to be considered when sizing a hydraulic motor.

E. Stiction has no impact on the torque requirements.