Unlocking Versatility: Pneumatic Grippers Revolutionize Electric Robots With Cost-Effective Precision

By John Proegler, PHD, Inc.

Combining a pneumatic power source for grippers on the end of electric robots provides the best of both technologies. In many cases, using the pneumatic end effector is the most cost-effective solution for grasping the parts the robot is handling.

Gripper Defined

A gripper is a device that grasps a part or object to be moved by the robot or other automation device. The gripper is like a human hand but, in most cases, less intricate and complex, although recently, more technologically sophisticated grippers have been designed that more closely mimic the human hand and fingers. Like your hand, a gripper provides the ability to grasp an object, hold it while it is being moved or manipulated, and then release it once the operation is completed. The gripper is just one type of end effector on a robot or automation device. Grippers come in a wide range of styles and sizes to handle an almost infinite range of objects. Grippers can be powered pneumatically or electrically, and they can include vacuum cups and bellows that expand to grasp an object.

Pneumatic Gripper Basics

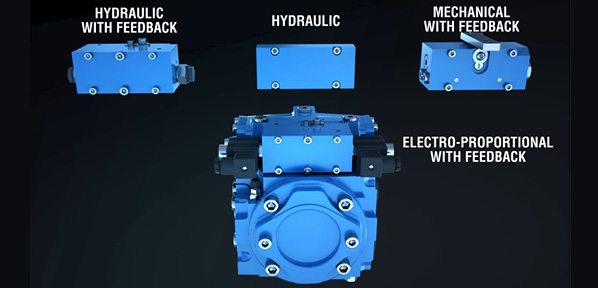

A pneumatic gripper operates by providing compressed air to the cylinder contained in the body of the gripper. A directional control valve controls the compressed air, which forces the cylinder’s piston up and down. The movement of the piston drives various types of mechanical linkage, causing the gripper’s jaws to open and close. The kinds of linkage and the jaw configuration allow for different types of jaw movement. These are typically either angular with pivoting jaws or parallel with linear jaw movement.

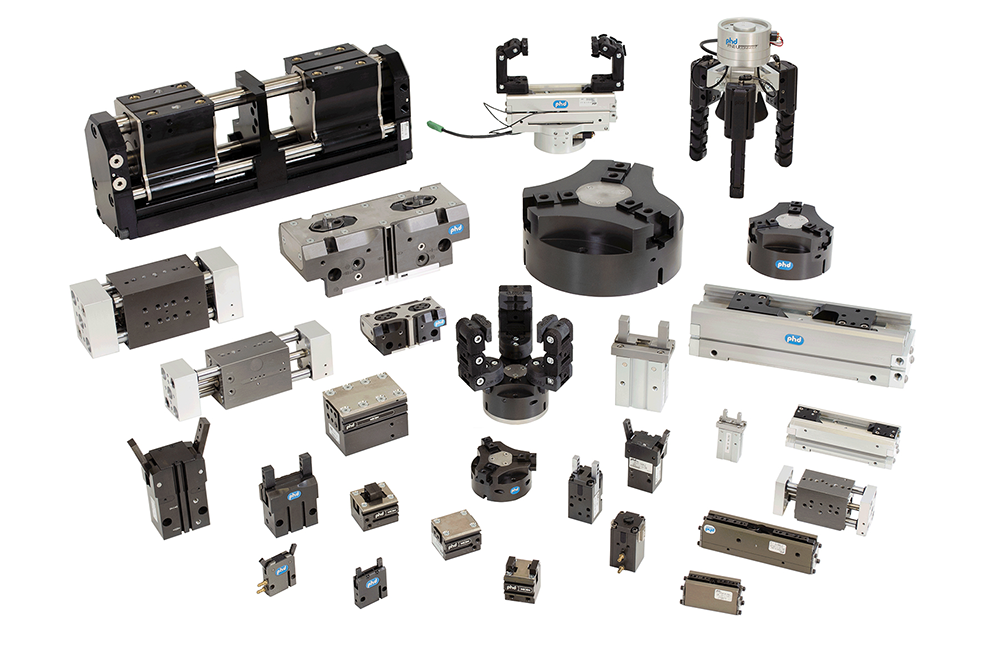

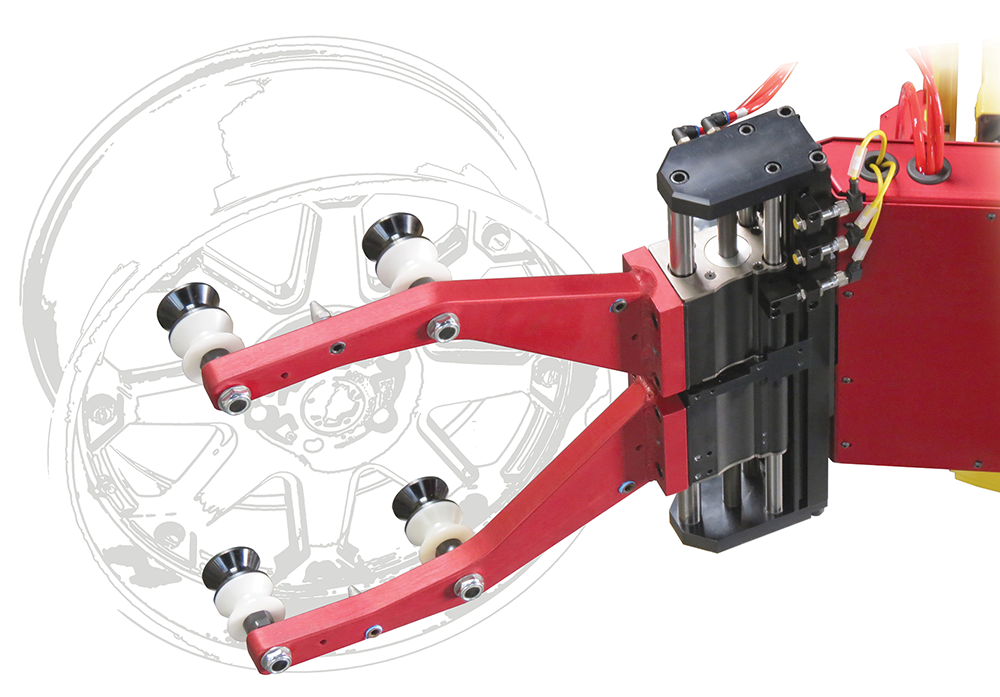

Standard pneumatic grippers come in a vast range of sizes and styles. These grippers can be very small and precise for grasping miniature parts such as electronic components and intricate medical devices. Pneumatic grippers are also available in very large configurations for gripping objects such as engine blocks and automotive wheels.

Jaw configurations vary widely, allowing the grippers to adapt easily to the grasped objects. Two-jaw and three-jaw units are common, and the grippers can be designed with multiple jaws for specific applications.

Various types of sensors on the pneumatic grippers provide inputs to the robot’s controller, indicating the position of the jaws. Some sensors are digital and provide an input at a specific point in the jaw’s travel. These indicate when the jaw is open or closed and can be adjusted to show the jaw position when a part is grasped. Analog sensors are also available on some grippers, providing constant jaw position feedback to the controller.

Customization

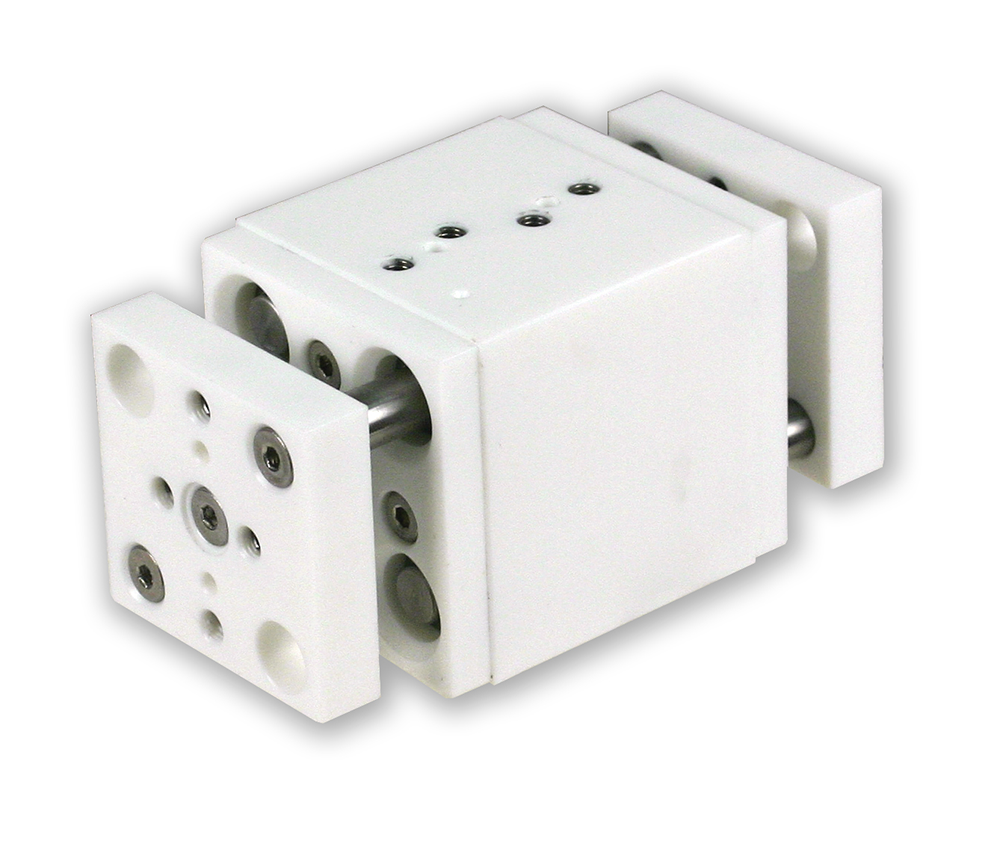

The mechanical characteristics of a pneumatic gripper allow for easy customization of the units for specific applications and environments. Units can be designed with multiple jaws for installing o-rings, for example. The grippers can be modified to function in harsh environments such as high temperatures or areas where a high degree of dirt or contamination exists. The material that makes up the pneumatic gripper can also be customized. For example, grippers can be constructed from plastic composites or food-grade materials for specific applications.

Pneumatic Gripper Advantages

There are many unique advantages of using a pneumatic gripper as an end effector on an electric robot. First, pneumatic actuators are known for having high force-to-weight ratios. This factor especially applies to a pneumatic gripper. Because of this efficiency, the gripper size and weight can be minimized, allowing for higher overall payloads carried by the robot. Second, pneumatic grippers have a rapid response time for opening and closing the jaws, thereby reducing dwell times for pick up and release, providing fast cycle times. Another advantage is that the cost of a pneumatic gripper is typically much less than that of an electric gripper.

Finally, there is a wide variety of standard pneumatic gripper configurations in the marketplace. The varied selection makes it easy to select a gripper that best fits an application, saving design time and providing shorter lead times. One particular feature of some pneumatic grippers is the ability to make the gripper ‘single acting,’ typically through the use of internal springs that provide retention of the part even if power is lost. This feature can be important for safety and to protect highly valuable parts that would be costly to drop.

Pneumatic Gripper Disadvantages

There are a few drawbacks to pneumatic grippers as compared to electric grippers. First, the pneumatic version requires a pneumatic power source and a control valve for opening and closing the gripper. However, most automation systems already use other pneumatic actuators, in which case the power source would be readily available. Another possible disadvantage is that the jaw travels and the jaw forces of a pneumatic gripper cannot easily be changed once the gripper is installed. A third drawback is that jaw positions are typically open or closed with no positions in between.

Ideal Applications

Despite the few disadvantages, many applications are ideal for pneumatic grippers as end effectors on electric robots. Pneumatic grippers are ideal for applications where the robot is handling parts that are a consistent size. When more flexibility is required, two or more pneumatic grippers may be employed on a single robot, made possible because of the lighter weight characteristics of these grippers. The lighter weight is also advantageous when the robot’s payload is critical. The lightweight gripper may allow for higher total payloads without increasing the robot’s size. Pneumatic grippers are also ideal for applications requiring high grip forces for handling larger loads due to their high force-to-weight ratio.

Application Considerations

There are some application considerations for using a pneumatic gripper on an electric robot. As stated earlier, a compressed air supply is required to operate the pneumatic gripper. The available consistent air pressure is an important application consideration. Typically, a minimum of 60 PSI should be used. It is important to ensure that the minimum air pressure used to select the gripper for the application can always be maintained. The grip force created by the gripper is in direct relationship to the input air pressure to the unit. Using the correct directional control valve is part of the air supply equation. The valve must have enough flow capacity to properly open and close the pneumatic gripper. The valve should also be capable of maintaining air pressure to the gripper throughout the grip cycle.

Proper sizing of the pneumatic gripper includes several factors in addition to the input air pressure. Jaw motion (angular or parallel), length of the tooling attached to the jaw, and the moment loads the jaws will encounter are all factors to consider. Calculations can be made using the published technical data provided by the gripper manufacturer. Often, software is available to help in the gripper selection process.

The design of the finger tooling that contacts the part is an important consideration. The tooling must be as light as possible yet able to handle the grip force and moment loads. Whenever possible, the finger tooling should be designed to conform to the part shape and encapsulate the part being gripped. The tooling also should allow the gripped part to be as close as possible to the gripper body, minimizing moment loads and helping with the grip force provided.

A pneumatic gripper with internal springs maintains grip force even if air pressure is lost. These grippers can be used as a single-acting unit with the internal springs providing the grip force or a double-acting gripper using both the springs and the air pressure to grip the part. In either case, the gripper should be sized so that the internal springs alone can maintain a hold on the part.

Pneumatic Grippers on ‘Cobots’

In recent years, there has been a trend toward the increased use of ‘collaborative’ robots, also known as ‘cobots.’ Cobots are typically power- and force-limiting. The robot can feel abnormal forces in its path and may be programmed to stop when it reads an overload in terms of force. The cobots are designed to dissipate forces in case of impact on a wide surface. As a result, the cobot may be used for direct collaboration with humans for various tasks without additional safety devices.

Cobots are typically highly adaptable and virtually plug-and-play, so a user does not need a great deal of experience to effectively program and apply the device. Some companies use cobots because they can be placed alongside humans. Others utilize them because of their extreme ease of programming, quick uptime, and great flexibility.

Since cobots used in human collaborative environments need to operate at lower air pressures to reduce the chance of injury, the tooling on the pneumatic grippers in this environment should be designed to encapsulate the part. If the cobot is being used for its ease of use rather than in a human collaborative environment, the pneumatic gripper can be run at high pressures, producing higher grip force and allowing for a smaller, lighter gripper, resulting in a positive effect on the total payload of the cobot.

Adapters are available that make it easy to attach pneumatic grippers to cobots manufactured by Universal Robots. These adaptors have embedded directional control valves to control an end-effector through the robot’s tool port. The system easily attaches to the cobot arm and is intuitively operated from the Universal Robot interface.

Summary

Pneumatic grippers on electric robots are a good combination of varying technologies. The electric robots provide a great deal of flexibility and accuracy. Pneumatic grippers offer a cost-effective, high force-to-weight ratio end effector on these robots. The wide variety of standard grippers, along with the ability to easily customize the units, makes them adaptable to a vast range of applications. The pneumatic gripper’s use on the popular robots provides even more application capabilities for these grippers.