Utility Expo Opens Today in Louisville

The Utility Expo, the largest event for utility professionals and construction contractors to glimpse the latest industry technologies, innovations, and trends, opens today at the Kentucky Exposition Center in Louisville.

The Utility Expo, the largest event for utility professionals and construction contractors to glimpse the latest industry technologies, innovations, and trends, opens today at the Kentucky Exposition Center in Louisville.

Covering more than 30 acres, the show has a number of educational sessions planned, including field classrooms on the show floor. The interactive, walking classrooms are 90-minute sessions led by industry experts. Attendees can choose from 28 sessions on topic such as fleet management, fleet accessories, safety, vegetation management, and aerial devices.

Attendees can also purchase on-demand materials, choosing from more than 60 sessions that they can access starting Oct. 1 and are available for a year. Topics include safety, business best practices, pipeline solutions, equipment technology, workforce development, underground solutions, drones, DOT updates, and aerial solutions.

A water pavilion education program organized by Storm Water Solutions and Water & Wastes Digest includes live demonstrations led by industry experts. Topics include asset management, best management practices, digitization and automation, energy efficiency, erosion and sediment control, and funding.

For more information, visit www.theutilityexpo.com/.

Among the more than 900 exhibitors, Parker Hannifin is highlighting several products with hydraulic applications.

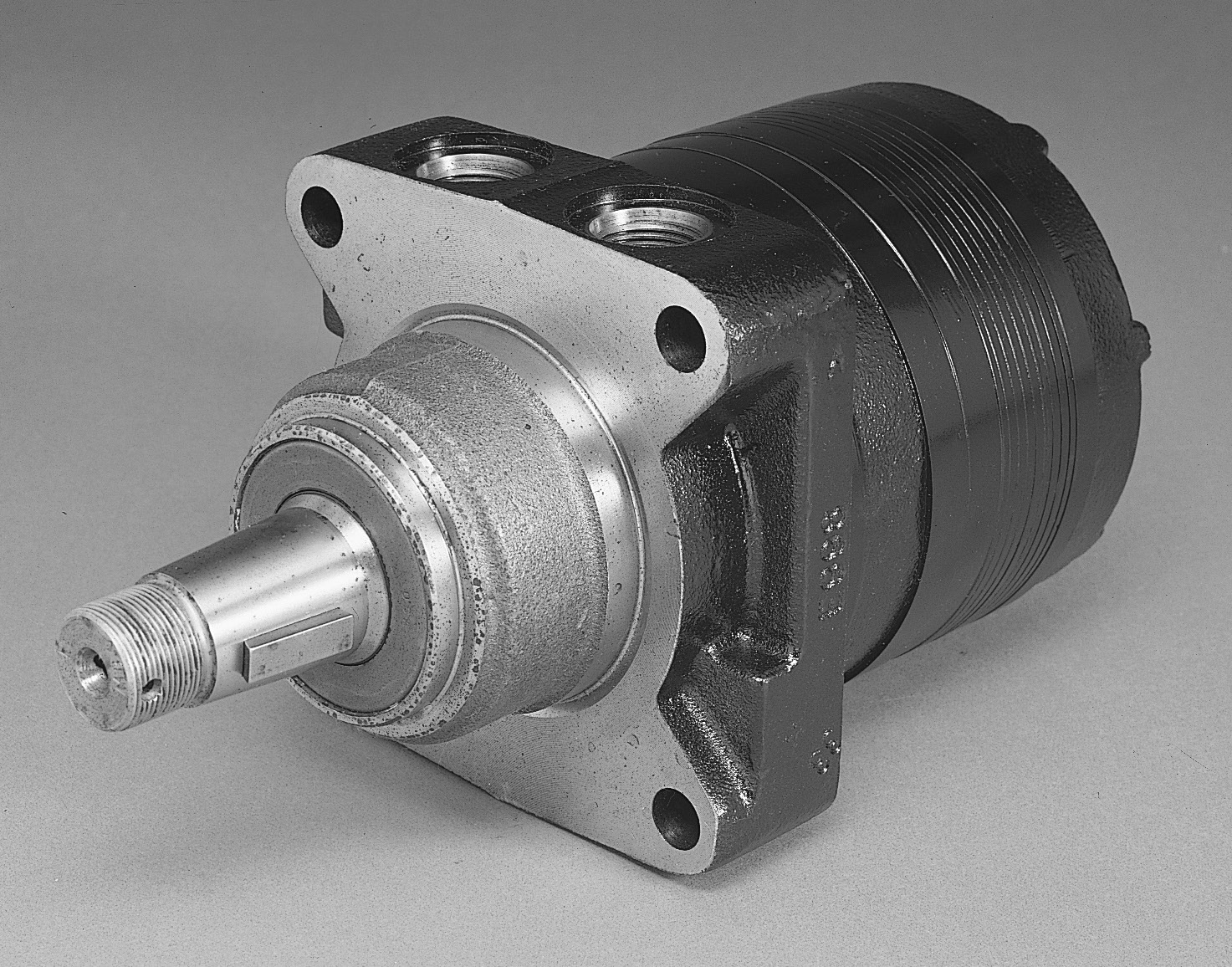

Torqmotor TGK Series

Parker’s Torqmotor TGK Series is a heavy-duty hydraulic motor that uses an extra heavy drive train in a standard size motor to deliver up to 19,000 lb-in torque, with intermittent pressure ratings to 4,000 psi. Maximum dynamic side load capability is 3,600 lbs. at the key. It is a durable orbital hydraulic motor with superior side load capacity, high pressure shaft seal and smooth low speed operation. Its high-power density allows for higher HP applications in a smaller space. Ideal for heavy duty applications such as vehicle propulsion, augers, chain drives, winches, and boom rotate. It features continuous oil flow across the splines for longer life, superior side load capacity, and smooth extra low speed operation. A high-pressure shaft seal is standard. Its innovative design eliminates the need for a case drain.

Parker’s Torqmotor TGK Series is a heavy-duty hydraulic motor that uses an extra heavy drive train in a standard size motor to deliver up to 19,000 lb-in torque, with intermittent pressure ratings to 4,000 psi. Maximum dynamic side load capability is 3,600 lbs. at the key. It is a durable orbital hydraulic motor with superior side load capacity, high pressure shaft seal and smooth low speed operation. Its high-power density allows for higher HP applications in a smaller space. Ideal for heavy duty applications such as vehicle propulsion, augers, chain drives, winches, and boom rotate. It features continuous oil flow across the splines for longer life, superior side load capacity, and smooth extra low speed operation. A high-pressure shaft seal is standard. Its innovative design eliminates the need for a case drain.

For more information, visit https://ph.parker.com/us/en/hydraulic-motor-with-exceptional-strength-and-durabilty-for-up-to-18630-lb-in-torque-torqmotor-tgk-series.

Chelsea 272 Series PTO

The Chelsea 272 Series Hot Shift 6-Bolt power take-off is Parker’s versatile medium-duty hot shift PTO. It is available in hydraulic or pneumatic/air shift with continuous torque capabilities up to 300 lbs ft. The 272 Series PTO is a reinvention that consolidates the 230, 231, 236, 238, 270, and 271 medium-duty hot shift PTOs into one series. The moving parts have been upgraded to withstand 300 lbs ft intermittently or continuously. The 272 has nine speed ratios, 18 shift options, and direct mount and driveshaft outputs. The direct mount options include Wet Spline technology (optional) for longer PTO and pump-shaft life, while the driveshaft outputs include Smart Start for high torque start-up conditions. It comes with integral air control valve.

The Chelsea 272 Series Hot Shift 6-Bolt power take-off is Parker’s versatile medium-duty hot shift PTO. It is available in hydraulic or pneumatic/air shift with continuous torque capabilities up to 300 lbs ft. The 272 Series PTO is a reinvention that consolidates the 230, 231, 236, 238, 270, and 271 medium-duty hot shift PTOs into one series. The moving parts have been upgraded to withstand 300 lbs ft intermittently or continuously. The 272 has nine speed ratios, 18 shift options, and direct mount and driveshaft outputs. The direct mount options include Wet Spline technology (optional) for longer PTO and pump-shaft life, while the driveshaft outputs include Smart Start for high torque start-up conditions. It comes with integral air control valve.

For more information, visit https://ph.parker.com/us/17553/en/272-series-powershift-pneumatic-hydraulic-6-bolt-power-take-off-pto.

Hydraulic Hose

Parker’s TOUGHJACKET hydraulic hoses feature special Parker-formulated polyurethane jackets and exceed industry requirements for abrasion resistance and durability of rubber hose by 650 times. The 563TJ hydraulic hose series offers the best change in length characteristics at +/-1%. This makes it an ideal solution for boom or cable track applications where long lengths are required. The SAE acceptable change in length specification is +2% to -4%. Most hoses shrink at least 2% in a constrained environment which can be disastrous for the hose and cable tracks. If 100 feet of hose is run in a boom, it must accommodate for the extra four feet of hose that will be required due to shrink or run the risk of the hose pulling the fitting off the hose or destroying the cable track. Constant and variable pressure TOUGHJACKET thermoplastic hydraulic hoses operate at 2,000-5,000 psi, while ultra-high-pressure. The Series 594TJ is an SAE 100R19-compliant 4,000 psi hydraulic hose with four-wire strength and two-wire construction. The Series 590TJ has four-wire strength in a two-wire construction and delivers a tighter bend radius than traditional rubber hydraulic hoses.

Parker’s TOUGHJACKET hydraulic hoses feature special Parker-formulated polyurethane jackets and exceed industry requirements for abrasion resistance and durability of rubber hose by 650 times. The 563TJ hydraulic hose series offers the best change in length characteristics at +/-1%. This makes it an ideal solution for boom or cable track applications where long lengths are required. The SAE acceptable change in length specification is +2% to -4%. Most hoses shrink at least 2% in a constrained environment which can be disastrous for the hose and cable tracks. If 100 feet of hose is run in a boom, it must accommodate for the extra four feet of hose that will be required due to shrink or run the risk of the hose pulling the fitting off the hose or destroying the cable track. Constant and variable pressure TOUGHJACKET thermoplastic hydraulic hoses operate at 2,000-5,000 psi, while ultra-high-pressure. The Series 594TJ is an SAE 100R19-compliant 4,000 psi hydraulic hose with four-wire strength and two-wire construction. The Series 590TJ has four-wire strength in a two-wire construction and delivers a tighter bend radius than traditional rubber hydraulic hoses.

For more information, visit https://promo.parker.com/promotionsite/toughjacket/us/en/home.

Parker’s low temperature thermoplastic hydraulic hoses feature optimum performance in cold temperatures, especially for applications requiring flexibility in cold climates with temperatures as low as -70°F (-57°C). The hoses are ideal for applications that involve hydraulic forklifts in cold or refrigerated areas, aerial lift construction trucks, agriculture equipment in cold climates, or material handling equipment in commercial freezers. Parflex low temperature hoses also feature a 10%-30% smaller O.D. than rubber and are up to 70% lighter and similar to 3TR18/30CT hose but with a lower operating temperature.

For more information, visit https://ph.parker.com/us/17573/en/low-temp-hose.