Basic Vacuum Schematics

In vacuum material handling, there usually are only a handful of separate components, such as a vacuum pump, inlet filter, control valves, and cups. This article explains the basic schematics and how they should be used to illustrate to the installer or end user how his new system works.

Schematic circuits should always be supplied with custom-made machinery, such as vacuum end-of-arm tooling, to aid the maintenance engineers in problem solving and the production engineers when they are looking for ways of improving efficiency after the installation or for adding components if the application changes years later. The body of a component should always have a schematic symbol on it, but when this is an adhesive label for instance, it could be illegible. Therefore, a master schematic will have the same schematic symbol for this component and how it is connected to associated devices.

A vacuum schematic symbol, just like in pneumatics or electrical schematics, does not indicate what the component looks like, but only how it functions. Therefore, the same schematic can be used for many different manufacturers of similar functional devices.

A vacuum schematic symbol, just like in pneumatics or electrical schematics, does not indicate what the component looks like, but only how it functions. Therefore, the same schematic can be used for many different manufacturers of similar functional devices.

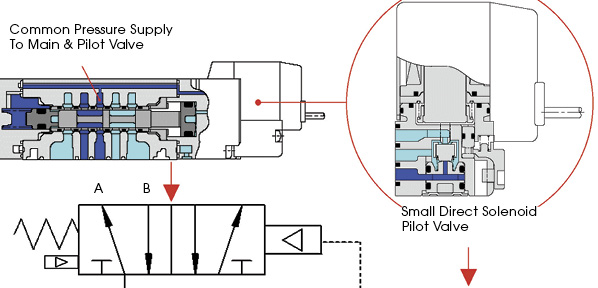

Fig. 1 shows a very simple circuit: (1) compressed air supply, (2) single-stage vacuum venturi, and (3) vacuum cup. Compressed air is continuously supplied to the vacuum venturi, and once the cup (3) grips the part, the compressed air has to be turned off to release it. Therefore, a compressed air valve needs to be added, as shown in Fig. 2, to achieve this. Note that a two-position valve SHOWS the two positions. In this example, each position is relevant to its two actuators, one being a spring (rest position) and one being solenoid (actuated position). Fig. 3 shows the valve in each position.

The left side shows the pressure port (P) CLOSED, and the supply port (A) is connected to exhaust port (R). The right side shows the valve actuated by the solenoid where (P) is now connected to the supply port (A) and the exhaust is closed. This is a normally CLOSED valve. The term “normally” means as it suggests: the valve, without any external power attached to it, has its pressure port CLOSED. The port indicators of P, A, and R are shown in both positions. This is unnecessary, of course, which is why the valve only has the ports highlighted on one side in schematic symbols. Remember, the valve schematic in Fig. 2 shows BOTH separate valve conditions.

The left side shows the pressure port (P) CLOSED, and the supply port (A) is connected to exhaust port (R). The right side shows the valve actuated by the solenoid where (P) is now connected to the supply port (A) and the exhaust is closed. This is a normally CLOSED valve. The term “normally” means as it suggests: the valve, without any external power attached to it, has its pressure port CLOSED. The port indicators of P, A, and R are shown in both positions. This is unnecessary, of course, which is why the valve only has the ports highlighted on one side in schematic symbols. Remember, the valve schematic in Fig. 2 shows BOTH separate valve conditions.

Fig. 4 shows more options that can be added to this circuit. A venturi external silencer (4) is now included, and a vacuum switch (5) indicates to the machine control that a specific vacuum level has been reached to enable the production cycle to continue. Also, between the vacuum cup (3) and venturi (2) inlet, a vacuum filter (6) has been installed to protect the venturi from dust or debris from the product being handled.

Fig. 4 shows more options that can be added to this circuit. A venturi external silencer (4) is now included, and a vacuum switch (5) indicates to the machine control that a specific vacuum level has been reached to enable the production cycle to continue. Also, between the vacuum cup (3) and venturi (2) inlet, a vacuum filter (6) has been installed to protect the venturi from dust or debris from the product being handled.

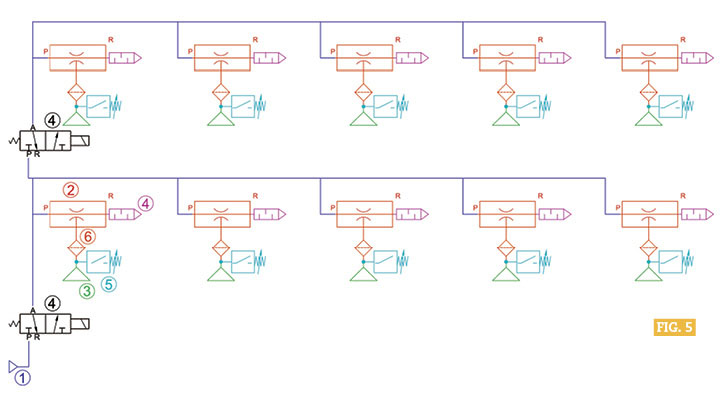

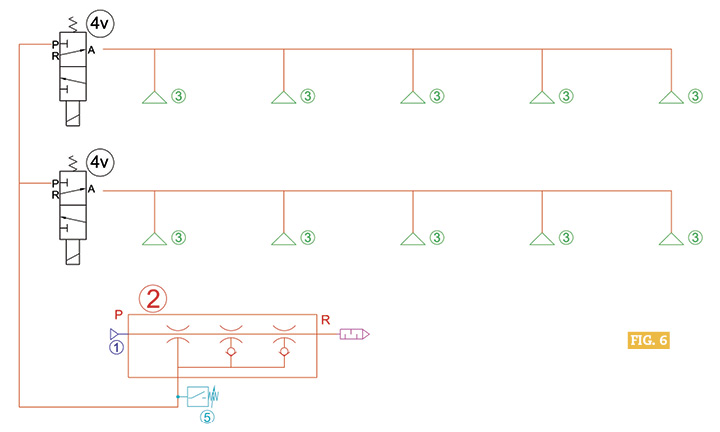

Fig. 5 shows a much larger circuit, but it uses the same components as shown in Fig. 4 with dual circuits utilizing two separate pneumatic valves. An alternative to this circuit is shown in Fig. 6, but instead of using compressed air valves to turn multiple venturi on and off, it uses one large multi-stage venturi and two vacuum valves to turn the vacuum on and off. Notice the direction of the arrows on the vacuum valve compared to the compressed air valve. The arrows indicate direction of air flow. The vacuum air flow direction is, of course, opposite to a compressed air supply.

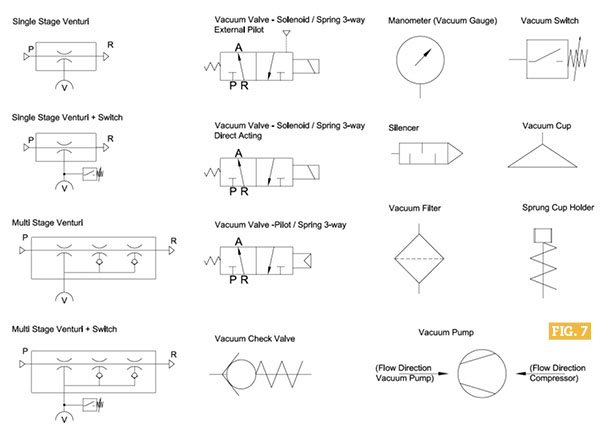

Fig. 7 lists an assortment of commonly used schematic symbols in a vacuum circuit. Different manufacturers use different forms of these symbols, but they fundamentally look the same.

This article is intended as a general guide and as with any industrial application involving machinery choice, independent professional advice should be sought to ensure correct selection and installation.

Great article. I needed a little refresher! Is there a good article to reference, similar to this, explaining the types of designs methods used to prevent suction loss in the event of a power outtage?

Great article. thanks.