Vacuum Technology With Compact Terminals Offer Versatility in Automation Systems

High quality. Energy efficiency. Compact and lightweight. Networkability. In the fast-paced world of automation, operators demand vacuum generation technology that meets these criteria. They require technology that is intelligent, scalable, flexible, and easy to install. Flexible vacuum automation terminals that offer short cycle times and have low space requirements are installed easily. They can be used directly on a gripper or moving axis to meet these important challenges.

Operators use vacuum components to build individual vacuum gripping systems that fit their needs and environment. Individual vacuum automation components and ready-to-connect gripping systems from Schmalz are used in a variety of industries and applications. The product range includes suction cups in numerous shapes, sizes, and materials for almost any application. The vacuum is generated pneumatically with compact ejectors, or electrically with powerful pumps and blowers. Valves, vacuum switches, and other components for controlling and monitoring the vacuum system are also included in the product range.

Challenges Solved

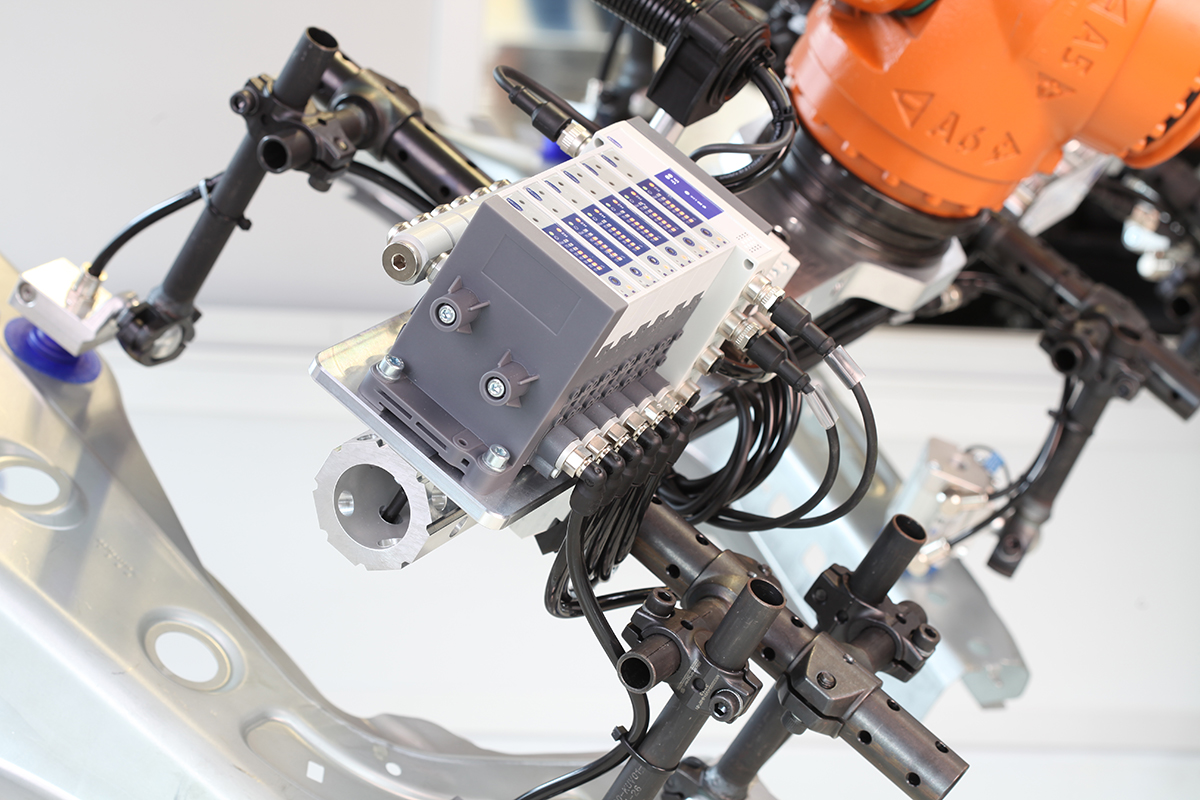

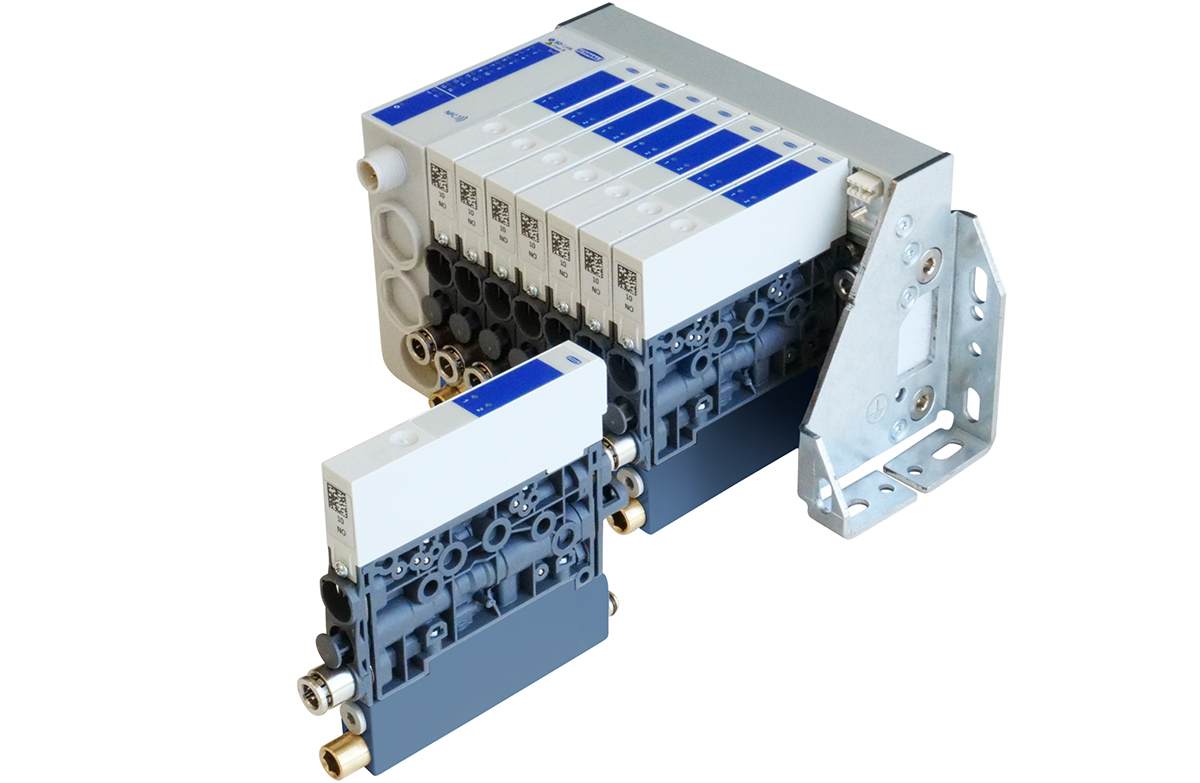

The SCTSi compact terminals and SCTMi mini compact terminals from Schmalz are powerful central units for vacuum generation, control, and monitoring. Particularly suitable for highly dynamic pick-and-place applications with extremely short cycle times, they fit on End-of-Arm tools while retaining payload capacity and not taking up too much space.

The terminals are ideal for metal and sheet metal fabrication, plastics, injection molding, and general industry where suction cup control is needed. They have multiple vacuum generators for the simultaneous and individual handling of different parts using only one vacuum system.

Terminals address the vacuum generation needs operators require in many ways:

- Payload capacity: The compact design allows for lightweight tooling.

- Flexibility of adding and subtracting compact generators: These units are very flexible and have just one cable. They can be added to end-of-arm tooling without taking up too much space or adding lots of weight to the tooling, all while maintaining the payload capacity.

- Connectivity: Via I/O-link, Ethernet IP, PROFINET, and EtherCat.

The compact terminals improve a variety of processes, including:

- Cutting evacuation times and lowering energy consumption, allowing for flexible use of different types of machines.

- Refining robotic arms operations, as terminals are Ideal for use on robotic arms.

- Building valves and vacuum switches into the unit, which reduces the number of parts to order or purchase.

- Reduced cabling, as there is just one cable for the unit versus for each vacuum generator.

- Controlling up to 16 separate vacuum circuits, allowing for full picking capacity

- Making it easier and faster to unscrew and remove from a robotic arm, therefore reducing the equipment downtime needed to clean with water or air

The SCTSi and SCTMi are used in laser and punching machines for feeding and precise removal of punched parts.

Networking in Industry 4.0 Systems

Variety, production optimization, and continuous energy and process control are the challenges of the future. To meet these demands, we need powerful, flexible, and energy-efficient vacuum systems. The Compact Terminal SCTSi Ethernet is a unit of several vacuum generators used to simultaneously and independently handle different parts within a single vacuum system.

The Ethernet connection means that recorded data can be viewed and used up to the control level, allowing for bidirectional parameterization and diagnostics in all conventional field-bus systems. Advantages include:

- Condition monitoring increases system availability by providing detailed analyses of the system’s condition and early detection of faults.

- Predictive maintenance improves the performance of gripping systems.

- Energy monitoring optimizes the vacuum system’s energy consumption.

Via an IO-Link master that can be integrated into the terminal, field devices can be connected via IO-Link and communicate directly with the PLC. Digital field devices such as sensors are integrated via digital input modules without separate I/O modules. The terminal is then the central control unit for vacuum gripping systems. The terminals also offer Near-Field Communication (NFC), with these advantages:

- Reliable communication via an energy-neutral point-to-point connection.

- Both statistical data, e.g. the serial number, and dynamic process data, e.g. switching points, can be read out and highly visible.

- Parameterization may happen to the SCTSi Ethernet directly using a smartphone app.

In addition, the SCTSi offers an integrated electronic sub-bus system. Electronic control can be implemented with just a single cable and comprehensive data communication via Ethernet and near-field communication. In addition, all ejectors can be separately programmed and controlled.

Air Consumption Savings

The SCTSi offers an automatic air-saving function. It switches off the suction function once a safe vacuum value has been reached until the next cycle, or until the vacuum falls below the safe vacuum value. Various configuration values and air-saving settings can be programmed separately for each ejector. As a result, the SCTSi reduces compressed air consumption by up to 80%.

Powerful central units for vacuum generation, control, and monitoring

Compact terminals control up to 16 separate vacuum circuits

Mini Compact Terminal Provides Space and Weight Savings

In 2023, Schmalz introduced the SCTMi mini compact terminal as an even smaller option for operators needing a compact solution. It can pick various parts using multiple zones and handle primarily airtight parts such as glass, metal, and plastic. It supports short cycle times, has low space requirements at 50% of the SCTSi footprint, weighs one-third the weight of the SCTSi, and offers simple installation. It also provides a high level of flexibility, thus meeting all the requirements for vacuum technology.

These mini compact terminals are ideal for use directly on the gripper or a moving axis. Short evacuation times and low energy consumption allow flexible use within different types of machines. They can be configured to contain up to 16 separate vacuum circuits, with each having a unique combination of suction rate and valve control. This scalability provides users with great flexibility as requirements change, as they can replace or supplement the ejector disks in minutes. The electrical and pneumatic control connections are on one level and ensure quick and easy mounting and uncomplicated expansion. This reduces the average integration time from two days to just four hours.

At the heart of the units are ejector slices based on the SCPM and SCPS compact ejectors, available with nozzle sizes from 0.3 to 1.2 mm (0.012” to 0.47”) in diameter and work very efficiently. They are particularly suitable for highly dynamic pick-and-place applications with extremely short cycle times.

The SCTMi mini compact terminals are available with an IO-Link communication interface. Also available are variants with a valve to meet design needs for vacuum circuits with a central, external vacuum generator.

Meeting Automation Needs of the Future

Flexibility, optimization of production processes, continuous energy and process control, and networkability are the challenges for future automation.

Vacuum systems must be powerful, flexible, lightweight, compact, and energy-efficient to meet these important needs. Compact terminals align with operators’ requirements specific to their automated gripping systems across key industries and applications.