World Premiere: ACE Presents Industrial Shock Absorbers as Digital Twins

Designers receive comprehensive data from ACE on all shock absorber types as digital twins so that they can test them virtually in the simulation model of their application

By Robert Timmerberg M. A., editor, plus2 GmbH, Düsseldorf, Germany

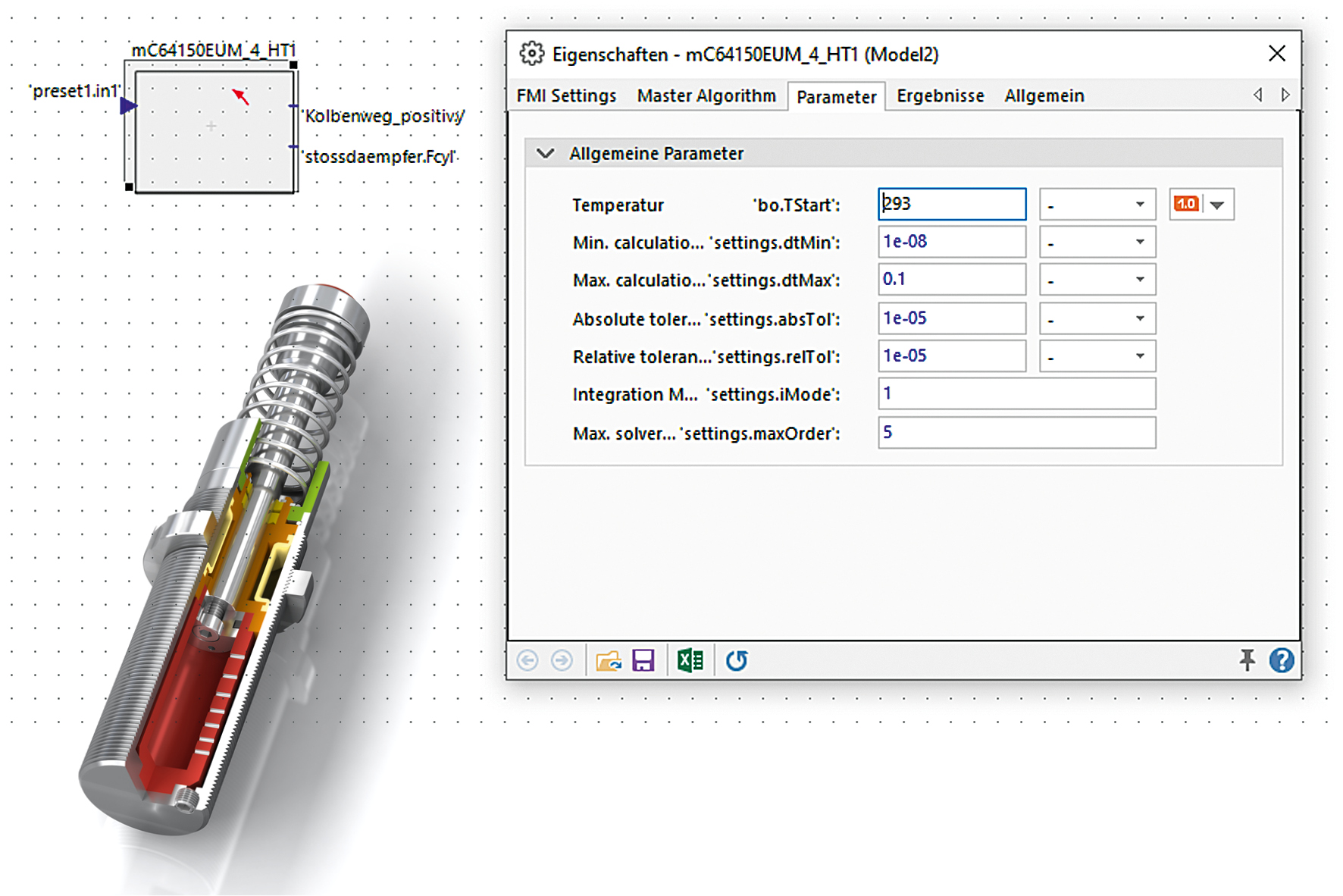

Langenfeld, Germany: Next to sizing software as well as CAD data and simulations, ACE Stoßdämpfer GmbH now offers engineers data from digital twins for easier integration into virtual models. ACE is the first supplier of industrial shock absorbers to provide customers with Functional Mockup Units (FMUs). It offers the possibility to integrate physical models of a supplier product, in this case industrial shock absorbers, into the customer’s own simulation models. This advantage is particularly evident with customized industrial dampers, as ACE is able to quickly provide prototypes as digital twins.

Industrial shock absorbers from ACE: Components of virtual prototyping

Upon request, ACE also offers to extract data for all standard industrial shock absorbers from its product catalog and hand them over to customers. The FMUs are equipped with the physical behavior of hydraulics, thermals and mechanics of ACE’s industrial shock absorbers. This makes it possible, for example, to calculate the exact influence of the input temperature on the damping behavior of the industrial shock absorber and to examine its effect on the overall design in advance. These and other properties make ACE’s digital twins an essential component for virtual prototyping and for dimensioning construction designs on the customer side. On the plus side, in addition to time and cost savings, there are also sustainability benefits, as fewer physical samples are needed to complete the development of a construction.

If customers want to use ACE’s FMUs, they need simulation software that includes an FMI (Functional Mockup Interface). Common programs that integrate ACE’s FMUs include Simulink and Adams.

Interested parties can find further information about ACE’s digital services via the links https://www.acecontrols.co.uk/uk/sizing.html and https://ace-cad.de/

For information about simulations and digital twins, please contact ACE’s engineer Christian Junghans at c-junghans@ace-int.eu directly.