Zero-Max Introduces Overhung Load Adaptors

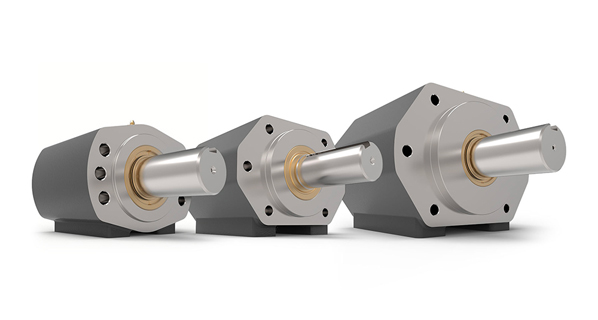

Zero-Max recently released three extra-duty overhung load adaptor models.

The OHLA designs feature a number of upgrades, including spherical bearings, enhanced sealing technology, stronger shafts, and a longer profile delivering increased operating life, heavier load capacities, and higher speed ratings.

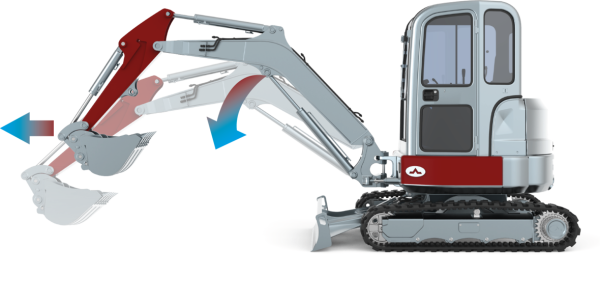

While the standard OHLA product line is designed to handle high loads at high operating speeds, these new extra-duty models are designed to maximize performance in the most demanding applications. They provide a solid, permanent mounting surface, eliminating premature motor or pump failure due to axial and radial overhung loads on a motor or pump shaft. They feature these design enhancements:

- Extended housing length for improved load distribution on the bearings, increasing load capacity and operating lifetime.

- Spherical roller bearings as standard for the best combination of high-load and high-speed capacity.

- Dual grease zerks with one grease fitting located above each spherical bearing to apply grease directly into both bearing assemblies.

- Heat-treated shafts with splined input bores as standard for handling higher torque and higher shock load applications.

- An O-ring seal at input for a consistent, positive seal between the hydraulic pump or motor and the OHLA.

- Special bidirectional dual-lip seals at the output shaft with two primary seal lips keep lubricant in the OHLA bearings and keep out dirt and debris. Typical dual lip seals have a primary lip seal for fluid separation on one side and a secondary lip for excluding contaminants on the other side. This new specially designed extra-duty seal has two opposing primary lip sealing surfaces to provide fluid separation and contaminant exclusion from both directions – inside and outside the OHLA. Additionally, this newly designed seal is rubber coated with stainless steel garter springs for added corrosion protection from the external environment, with enhanced protection from debris and other contaminants.

For more information, call (800) 533-1731 or visit www.zero-max.com.