Zero-Max Offers Overload Safety Devices

Zero-Max overload safety devices protect motor and drive systems from overload while offering options to withstand corrosive environments and necessary washdowns. These options provide protection from direct water spray, washdown chemicals, detergents, chemical exposure, and debris.

Zero-Max overload safety devices protect motor and drive systems from overload while offering options to withstand corrosive environments and necessary washdowns. These options provide protection from direct water spray, washdown chemicals, detergents, chemical exposure, and debris.

These unique overload safety devices are ideal for applications ranging from food processing, packaging, commercial dishwashers, industrial parts washers, and any applications with similar challenging operating conditions.

Providing both torque limiting and coupling functions in a compact design, Zero-Max overload safety devices can operate as a coupling and an overload safety device connecting two inline shafts in a power transmission system. Power take-off models are also available for use with chain or belt drives. The overload safety devices protect motor and drive systems from excessive overloading and potentially expensive system jam ups, especially after factoring in for equipment repairs, product loss, and any downtime incurred resulting from a jam up. They also offer easy re-engagement, allowing the system to be running again as quickly as possible.

Standard Torq-Tender overload safety devices have precision-machined steel bodies with standard black oxide exteriors. Enhancement options for washdown and corrosion protection include:

- Nickel-plated exterior with stainless steel hardware for a moderate level of protection. High-phosphorous nickel plating can withstand washdown chemical exposure without staining or discoloration.

- Stainless steel exterior and hardware components for a higher level of protection. The grade of stainless can be selected based on the protection level needed. Stainless steel springs can be substituted internally where needed.

- O-ring seals added to seal between the driver and driven halves of the Torq-Tender provide added protection from exposure to water, chemicals, or debris.

- Lubrication options include food-grade grease and dry lube coating where needed. Special greases are available for specific application requirements.

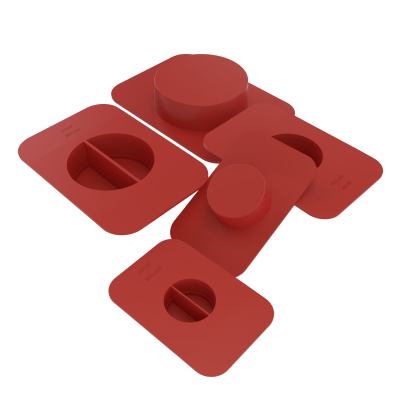

Standard H-TLC overload safety devices have a robust composite body with plated hardware components that provide satisfactory protection for most applications. Enhancement options for washdown and corrosion protection include:

- Stainless steel exterior hardware components for a higher level of protection

- Stainless steel springs can be substituted internally where needed

- Food-grade grease available where needed. The H-TLC can also operate without grease in certain applications due to its robust composite construction.

Both Torq-Tender and H-TLC models are available in a variety of mounting configurations, including use as a coupling model or as a power take-off model for use with chain or belt drives.

Actuating pin or actuating disc options are available for interfacing with a limit switch, proximity switch, or other sensing device to signal that an overload is occurring, or to shut down the drive motor when an overload occurs. This automated shut-down prevents excess wear on the machine’s driveline components.

For more information, call (800) 533-1731, email sales@zero-max.com, or visit www.zero-max.com.