Displacement Cylinders vs. Regeneration Circuits

When a cylinder with a long stroke is required, there are additional design considerations. Long-stroke cylinders are subject to compression stresses like any other cylinder, but buckling is another factor. Buckling can occur when long, slender cylinders are exposed to forces well below compressive stress limits. The classic example is a yardstick. Stand a yardstick on end and push on the top. Only a small force is needed to make the yardstick bow to one side. A slender cylinder has the same tendency. To counteract buckling, cylinder components are made larger in diameter.

The disadvantage of larger cylinder components is that larger cylinders require more fluid to extend. More fluid could be provided by a larger displacement pump, but there are more efficient ways to achieve the same result. In this article, we investigate displacement cylinders and regenerative circuits as effective ways to provide buckling resistance without increasing the pump displacement.

DISPLACEMENT CYLINDERS

Displacement cylinders are single acting. That means pressurized fluid is needed to extend but not retract. Common applications include dump trucks, forklifts, and scissor lifts. In those types of equipment, pumps extend the cylinder and gravity retracts the cylinder. Conventional single-acting cylinders can be used for these applications, but in this example we have oversized the cylinder to improve buckling resistance.

A displacement cylinder has several advantages over a double-acting cylinder. The first advantage is the number of seals. A displacement cylinder does not have piston seals. Fewer components mean fewer things to fail. Without piston seals, the cylinder rod extends when fluid entering the cylinder expands the internal volume. The only way the internal volume can expand is by extending the rod.

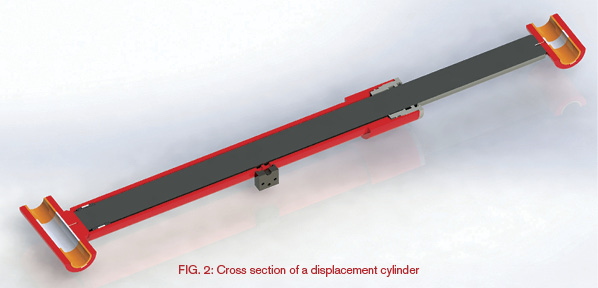

Because displacement cylinders are single acting, only one port is needed. That port can be located anywhere on the cylinder body. The cylinder in Fig. 1 has the port located near the middle for plumbing convenience. The section view in Fig. 2 shows the inside of the same cylinder.

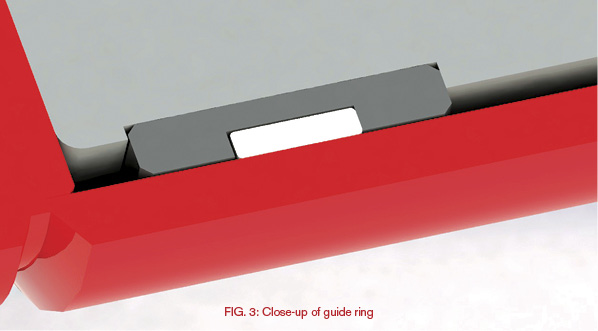

In Figs. 2 and 3, the wide, light gray rectangle near the base end of the cylinder is not a piston seal but a guide ring. Fluid passes from one side of the guide ring to the other through internal passages in the piston (not shown). Guide rings slide smoothly on the bore of the cylinder to align and center the piston while preventing scoring or galling.

Displacement cylinders have an advantage over conventional cylinders when it comes to the extend speed. Fluid entering the cylinder extends the rod as a function of the rod diameter, not the bore as in a conventional cylinder. That means a smaller pump can be used to produce the same rod extension velocity.

One final advantage is the reduced plumbing requirements. Displacement cylinders do not have a retract port, so there is no retract hose. Fewer hose connections mean fewer potential leak points.

As mentioned earlier, the rod diameter dictates the extend speed, but it also controls the extend force. Only the rod diameter area is used when calculating the extend force.

REGENERATIVE FLOW

A regenerative circuit (sometimes shortened to “regen”) provides many of the advantages of a displacement cylinder plus one additional benefit. Regen can be applied to double-acting cylinders. When extending, regen circuits redirect fluid that returns to the tank in a conventional double-acting cylinder. Regen cannot be applied to retract a cylinder due to the net area disadvantage.

Regen circuits are often used to reduce cycle times. In this example, the long stroke dictated a larger rod to resist buckling tendencies. In turn, the larger rod requires a larger piston, even though the larger bore may not be required to meet the extend force requirements. The result is a low-pressure requirement in an oversized piston with a large flow requirement. Regeneration overcomes that deficiency.

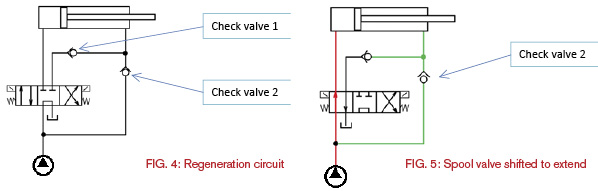

The key feature of regeneration is to take advantage of the fluid exhausted from the rod port. Consider the simplified schematic in Fig. 4. This is just one of many variations on full-time regen.

In Fig. 4, the directional control valve is in neutral and fluid is directed to the reservoir through a common tandem center valve. In the neutral position, check valve 2 prevents any pressure in the tank line from entering the rod port of the cylinder, possibly causing the rod to retract unintentionally. One way pressure might increase in the return line is if a return filter (not shown) was dirty. Fluid trapped in the base end of the cylinder by the directional control valve would prevent large unintended motion, but internal spool leakage may allow slow speed drift without check valve 2.

This is just one of several configurations. Regeneration circuits can also be used with variable-displacement pumps. Electrically operated valves (shown) can be replaced by manually operated valves as long as the tandem center is used.

In Fig. 5, the directional control valve is shifted so as to extend the cylinder. Fluid leaving the rod port passes through check valve 2 and combines with the fluid going to the valve. The fluid flows this way for a simple reason.

REGENERATION EXPLAINED IN TWO SENTENCES

Pressure is equal on both sides of the piston, but the larger area generates a larger force. The piston rod extends because there is greater force on the base side of the piston.

Significant increases in extend speed are possible. The flow rate and cycle times are calculated using the rod area, just like the displacement cylinder. The annular area times the pressure is the amount of force that is lost when extending. Just as in the displacement cylinder, the force available during regen is a product of pressure and the rod cross sectional area. Like most things in engineering, there is a compromise. The advantage of speed gained from a regen circuit comes at the price of force from a cylinder. That’s okay in this slender cylinder example because it had to be oversized to avoid problems with buckling.

Significant increases in extend speed are possible. The flow rate and cycle times are calculated using the rod area, just like the displacement cylinder. The annular area times the pressure is the amount of force that is lost when extending. Just as in the displacement cylinder, the force available during regen is a product of pressure and the rod cross sectional area. Like most things in engineering, there is a compromise. The advantage of speed gained from a regen circuit comes at the price of force from a cylinder. That’s okay in this slender cylinder example because it had to be oversized to avoid problems with buckling.

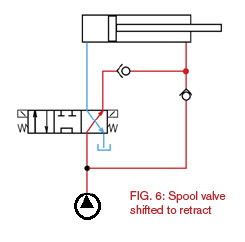

Regen does not influence cylinder speed when retracting the cylinder, as shown in Fig. 6.

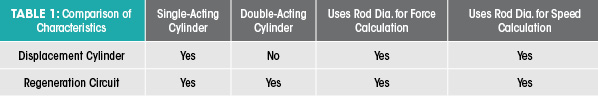

Displacement cylinders and regeneration circuits can be treated the same with regards to extend force and required pump flow. Understanding the differences will help you decide which to use and when. Refer to Table 1 for a comparison of characteristics.

There are many other versions of regenerative circuits. There are full-time and part-time regen circuits that disable regeneration automatically based on pressure. Each circuit offers an advantage in certain applications. We won’t go into them here, but for more information on these circuits, visit the Books and Publications page of the International Fluid Power Society website (www.ifps.org).

For more information: Robert Post, CFPHS, is an application engineer for Bailey Hydraulics, as well as a 2017 IFPS director-at-large. He can be reached at Robert.post@baileynet.com.