Control and Prognostic of Electro-Hydraulic Machines

This column will bring you the progress of the pre-competitive research being conducted at member universities that are part of the CCEFP network. This research will help give insight into the future direction of fluid power.

The Center for Compact and Efficient Fluid Power (CCEFP) holds a monthly forum, highlighting research, workforce, and special topic presentations.

CCEFP is a network of fluid-power-research laboratories, academic faculty, graduate and undergraduate students at nine universities. It is also a National Science Foundation Research Center. For more information on CCEFP, visit www.ccefp.org.

Since 2014, the National Fluid Power Association (NFPA) Foundation has supported and is helping to expand the pre-competitive fluid-power-research activities of the CCEFP, dramatically increasing the number of institutions and students impacted by its research program. For more on NFPA, visit www.nfpa.com/aboutnfpa/missionfocus.aspx.

Project Leader: Andrea Vacca, Associate Professor, Agricultural and Biological Engineering Department, School of Mechanical Engineering

Institution: Maha Fluid Power Research Center, Purdue University

PURPOSE

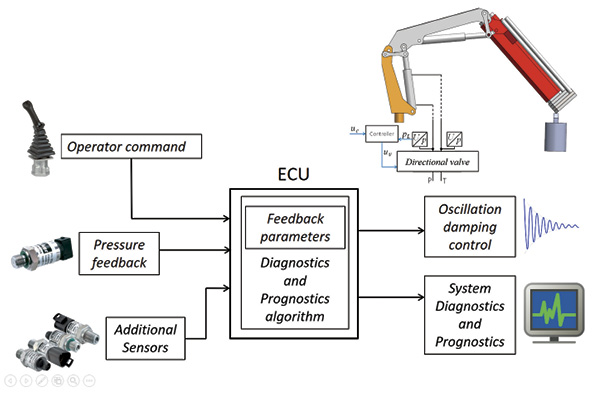

This study aims at combining advanced control techniques of hydraulic control systems, which are enabled by the use of modern electro-hydraulic (EH) components, along with system diagnostics and prognostics. Despite the generality of the proposed approach, for modeling and experimental validation purposes, the research takes as reference the case of a hydraulic crane for truck applications. For this reference case, the team at Purdue has already developed controllers for the EH valves which are able to reduce the oscillation at the booms up to 70%, as well as controllers suitable for the use of energy-efficient independent metering valves.

The research will demonstrate how the parameters calculated in real-time by these controllers can also be used for monitoring the health of the hydraulic components of the entire hydraulic system, for diagnostic and prognostic purposes. The combination of advanced control techniques and Prognostics and Health Management (PHM) algorithms proposed in this research will help to advance the field of EH machines. Future machines using combined EH control and PHM algorithms will leverage the known advantages of advanced EH control (increased safety, higher productivity, reduced energy consumption), but will also use condition-based maintenance, which is more cost-effective than current time-based (or failure-based) maintenance approaches.

PROGRESS

This project has focused on investigating advanced EH control techniques for oscillation damping and independent metering control, based on the real-time evaluation of cost functions from pressure sensors installed on the machines. The value of the cost function was proven to have additional significance with respect to faults occurring at the hydraulic components of the system. With heuristic data-driven methods, based on Neural Networks, the team has worked with the minimum number of additional temperature and pressure sensors in the system that allows for a complete identification of faults occurring at the supply pump, at the hydraulic control valves and at the linear actuators.

Recent results from a detailed simulation model of the hydraulic crane showed the effectiveness of the proposed PHM method with a limited number of pressure sensors (two for each hydraulic function) and temperature sensors.

NEXT STEPS

The current activities of the project focus on an extensive validation of the PHM algorithm on the instrumented hydraulic crane available at the Maha Fluid Power Research Center, in order to reproduce faults experimentally. Next steps also involve the formulation and implementation of stochastic approaches for the prediction of the remaining useful life of the hydraulic components.