A Rolling Steel Mill Had Trouble With the Roll Removal Circuit Trying To Eject a Roll

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training.

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training.

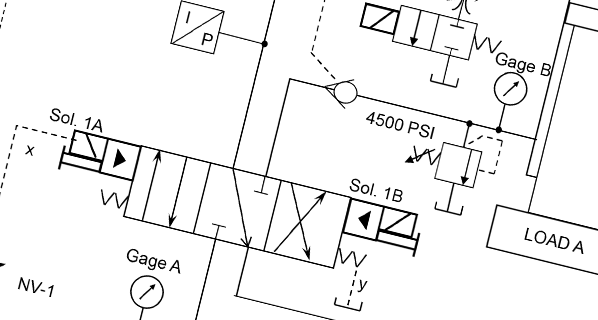

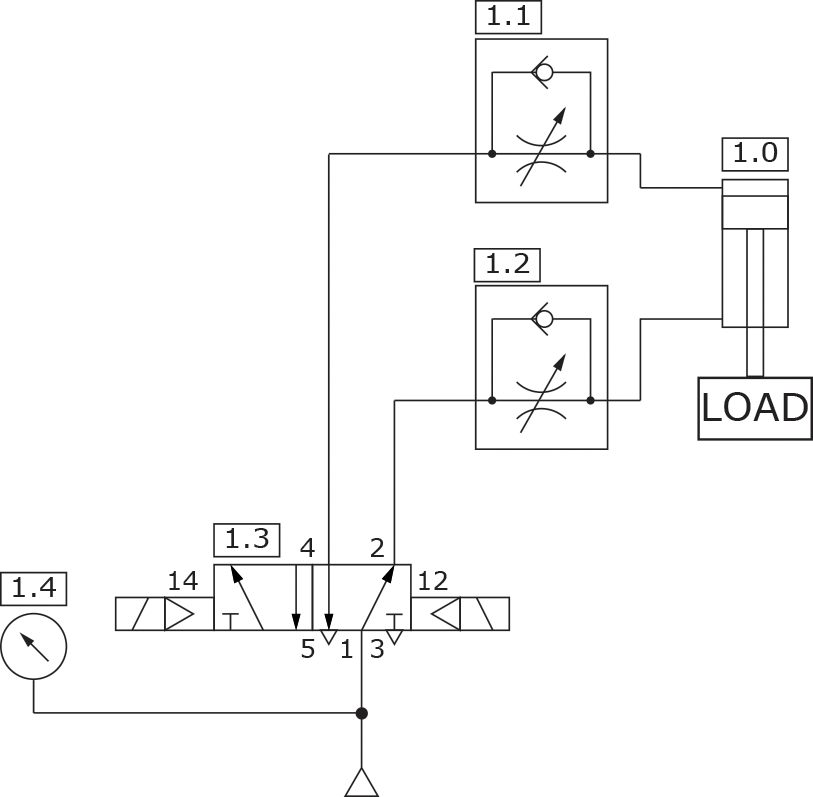

The circuit attached shows the hydraulic system used for roll removal at the end of the line. They could remove small rolls with no problems, but the larger rolls would move very slowly or not at all. This required the operator to use an overhead crane that slowed down the production cycle time.

The main system pressure was set at 13.8 MPa (2,000 psi) and the pressure reducing valve output was still reading 3.9 MPa (572 psi).

Any idea what could be causing the problem?

See Solution

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.