Addressing Component Interaction Complexity in Fluid Power Simulations

Elements of image furnished by Adobe Stock | NKmotion

By Michael Hoffman, Manager of Engineering Hydraulic Systems at Bailey International.

Fluid power simulations are becoming increasingly integral to modern engineering design. These days, accurate simulations can mean the difference between a functional prototype and months of iteration.

As both the pace and complexities of fluid system design continue to rise, engineers are looking to simulation and virtual testing more than they ever have.

The Growing Importance of Fluid Power Simulations

Fluid power technology encompasses the use of liquids (hydraulics) and gases (pneumatics) to transmit power. These systems have become ubiquitous in everyday life. From heavy machinery to the brakes on your car, fluid power is everywhere. With the ever-increasing pace of technology and innovation, simulations are also becoming increasingly critical to engineering success.

The most common way we think about simulations’ impact on product development is by reducing the need for physical prototypes and testing. While prototyping and physical testing are still key to the final validation of a design, an accurate simulation allows the engineers to virtually evaluate and validate a design and, when necessary, make improvements before a single part has even been made. This reduces total project time and costs. Whether optimizing for speed, size, efficiency, cost, or something else, simulation enables the engineers to push the boundaries and try new things rapidly. Different options can be evaluated quickly and easily so that companies can be sure the development path they choose is the right one.

The Challenge of Component Interaction Complexity

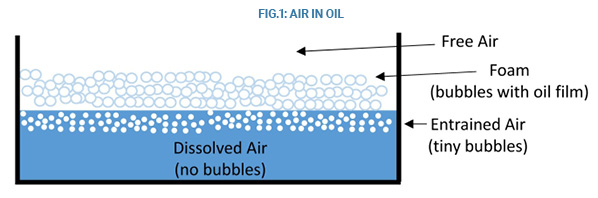

One of the biggest hurdles in modern simulation is accounting for the interactions between components. Component interactions can be highly dynamic, but even in cases when the interactions aren’t particularly significant individually, once you have many elements involved, the physics can get quite complex and must be accounted for. Component variables such as pressure drop, flow rate, and internal leakage can all impact system behavior in unexpected ways. This complexity requires a deep understanding of fluid dynamics, component design, and system integration to develop accurate simulations. You must also account for general factors of fluid compressibility, environmental factors, and temperature changes. It is critical to accurately model these factors to predict behavior.

Failing to account for these complexities can lead to inaccurate simulations, which can result in suboptimal or even dangerous designs. In the past, this has led some companies away from simulation-based design approaches and back to iterative build-and-test methodologies. As technology has improved though, simulation software has become better at accounting for these interplays and even multi-physics factors, which is continually making it easier and more efficient to simulate increasingly complex systems.

Approaches and Technologies

There are many different simulation technologies in use today. Let’s look at a few of the major ones and then discuss how they are being utilized in conjunction and, in some cases, integrated together into single packages to improve accuracy and repeatability.

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are related, but for simple classification purposes, FEA is for solids and CFD is for fluids. (I know the programmers out there are hating me right now, as FEA is great for heat transfer in fluids and even some fluid dynamics problems, and some mathematical approaches are technically both. But for clarity here, we will use them in this over-simplified manner.)

So then, why are we talking about FEA in an article about fluid power simulation? The simple answer is because it matters. The fluids act upon the solids and the ways in which the solids react, both to the fluid and with the environment around them. This all feeds back into the fluid, which impacts the system, and is where multibody dynamics (MBD) simulations and Hardware in Loop (HIL) testing/modeling come into play.

Multibody dynamics help to quantify the way the entire system reacts in various scenarios. This data can then feed back into the FEA and CFD analysis to quantify how they respond. This loop can be iterated until everything is accounted for. And while this is an iterative approach, it’s still faster than build-and-test approaches and provides a much better understanding of exactly what’s happening so that engineers can apply precise solutions in the right spots instead of broad catch-all solutions, which are common in build-and-test situations.

But what about the complex ways that the off-the-shelf components we’re using respond to the fluctuations in our system? This is where HIL comes in. While it makes sense to iteratively simulate things that don’t exist, when we have access to a physical part, it’s often best to just test it. Using a good test bench, we can take the system behavior data from our simulations, subject the physical component to those conditions, and measure the way the component responds and the effects of those responses downstream. This data inherently accounts for the multibody and structural interactions within the component. This data can then be fed back into our simulations to further iterate and improve the accuracy of the results.

Modern engineering software now offers integrated tools that combine FEA, CFD, MBD, and in some cases, even HIL data. That’s right – some simulation software companies are now taking the proactive approach of aggregating the response and performance data for a wide range of components from various manufacturers and generating component-specific simulation models for use in their software. These models are created from the data shared by the manufacturer from their own HIL testing. This cooperation is great for everybody. For manufacturers, having the virtual version of their product readily available in mainline simulation software gives their product greater visibility while simultaneously lowering the bar for validating their components’ compatibility by allowing the system designer to make use of the existing test data. This integration allows for seamless multi-physics simulations, ensuring all aspects of a system are accurately modeled, which accelerates the design process for everyone involved.

The ability to accurately simulate component interactions has a profound impact on product design and development cycles. With reliable simulations, the need for iterative prototyping is significantly reduced, allowing for faster progression from concept to production. Accurate simulations enable engineers to optimize every aspect of a design, leading to higher performing, more efficient products.

Also, simulating real-world conditions allows for thorough testing and validation, ensuring products meet rigorous safety and reliability standards.

The Future Outlook for Fluid Power Simulations

The future of fluid power simulations is bright, driven by continuous technological advancements and the increasing complexity of engineering challenges. As simulation tools become more powerful and accessible, and cooperation continues to improve between component manufacturers and the simulation software companies that support the industry, engineers are increasingly able to push the boundaries of what is possible. This will lead to further innovation in product design and development.

Emerging Trends

- Real-time simulations: Faster computational capabilities are enabling quicker results and real-time simulations are becoming more viable, allowing engineers to interactively explore design changes and their impacts efficiently.

- Cloud Computing: Leveraging cloud resources can dramatically increase simulation power and accessibility.

- Enhanced AI Integration: AI will continue to grow, providing even more accurate and efficient simulation tools.

The Evolving Role of Engineers

Engineers are poised to play a pivotal role in leveraging these up-and-coming technologies. Their expertise in physical systems, coupled with proficiency in advanced simulation tools, is critical to driving innovation.

Addressing the complexity of component interactions in fluid power simulations is a challenge, but advancements in computational methods, AI, and integrated simulation platforms are enabling highly accurate modeling of these interactions. This progress is revolutionizing product design and development cycles, leading to faster, safer, and more efficient engineering solutions.

To capitalize on these advancements, engineers must remain informed and continually hone their skills. By effectively learning new tools, they will be well-positioned to spearhead the next wave of innovation in fluid power technology.