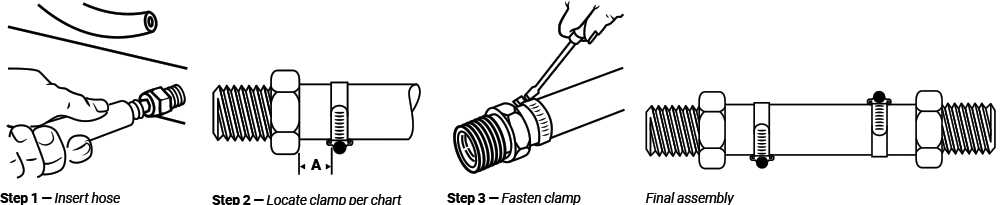

Attaching Clamps for Proper Assembly

Low-pressure hose assemblies require properly placing the clamps so that they will seal and retain the fitting. The clamp position “A” dimension is very important and is found in the manufacturers’ catalog charts.

Hose Clamp Style Recommendations

For low-pressure joints, up to 7 psi, a standard worm drive clamp is recommended. For joints with higher pressure that do not exceed 50 psi, a constant pressure clamp is recommended (T-Bolt, Belleville, and Wave Liner). For pressure lines exceeding 50 psi, a T-Bolt clamp or hose assembly with crimped fittings should be used.

Test Your Skills

1.What is the most important consideration when assembling clamp-type hose assemblies?

A. Hose and fitting from same manufacturer.

B. Length of assembly and the dimension of the clamp.

C. End fitting and hose compatibility.

D. Clamp location.

E. Length of hose and clamp.

See Solution