Canfield Connector Develops Custom Design for Conveyance Technology

By Todd Harmon, Vice President, Canfield Industries.

Countless industries across the United States rely on conveyor belt systems.

Modern manufacturing and logistical operations depend upon efficient conveyance systems operating in the background both day and night. Conveyor systems are utilized to quickly transport goods of every sort, from raw materials in factories to finished goods on store shelves.

These vital components of modern industry are designed and built by conveyor system manufacturers who have the task of helping their customers move product in a way that is both quick and efficient. A large piece of this puzzle is using modern technology to ensure that products are not damaged or lost as they move down the line.

A lack of proper control for conveyance systems produces a cascading negative effect to the operations of the entire system involved. Without precise control, operators within a conveyance system may experience inconsistent spacing, misalignment, or even a product jam. This can result in damage to the product, costly downtime, and delays. Products traveling erratically may even result in safety issues for personnel or a missed deadline for customer deliveries.

All in all, proper automation for conveyor systems is vital in modern day industrial operations and requires careful harmony of sensor technology and valve integration for conveyance control.

This need for reliable automation led one manufacturer of conveyance systems to reach out to the experts at Canfield Connector for help in designing a system with the ability to effectively sense and control the flow of product for their end users.

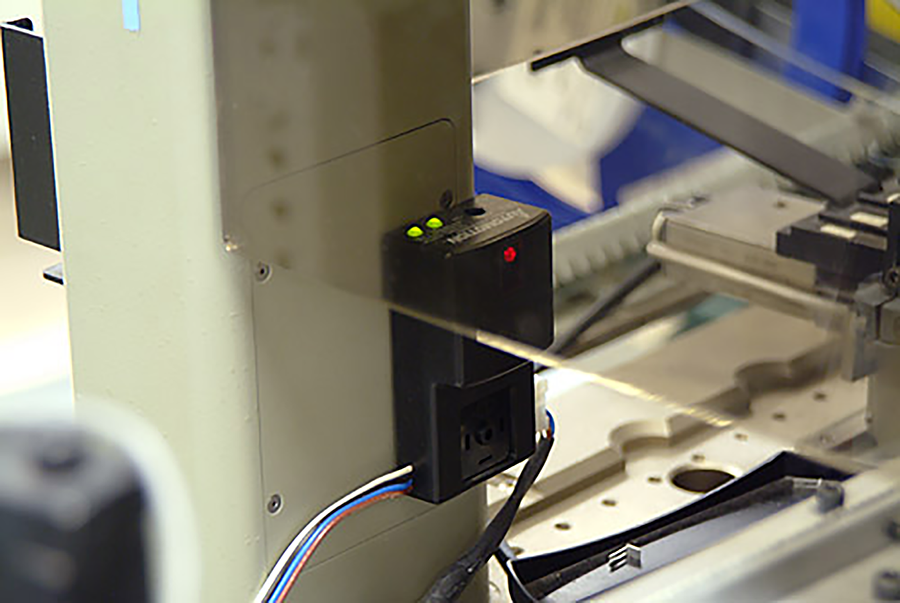

Canfield Connector was challenged with development of the optical portion of the design to supply an electrical output to trigger a pneumatic signal. Using the in-house capabilities of design, board manufacturing and injection molding, Canfield Connector developed a custom optical solution that adapts directly to the customer’s conveyor channel.

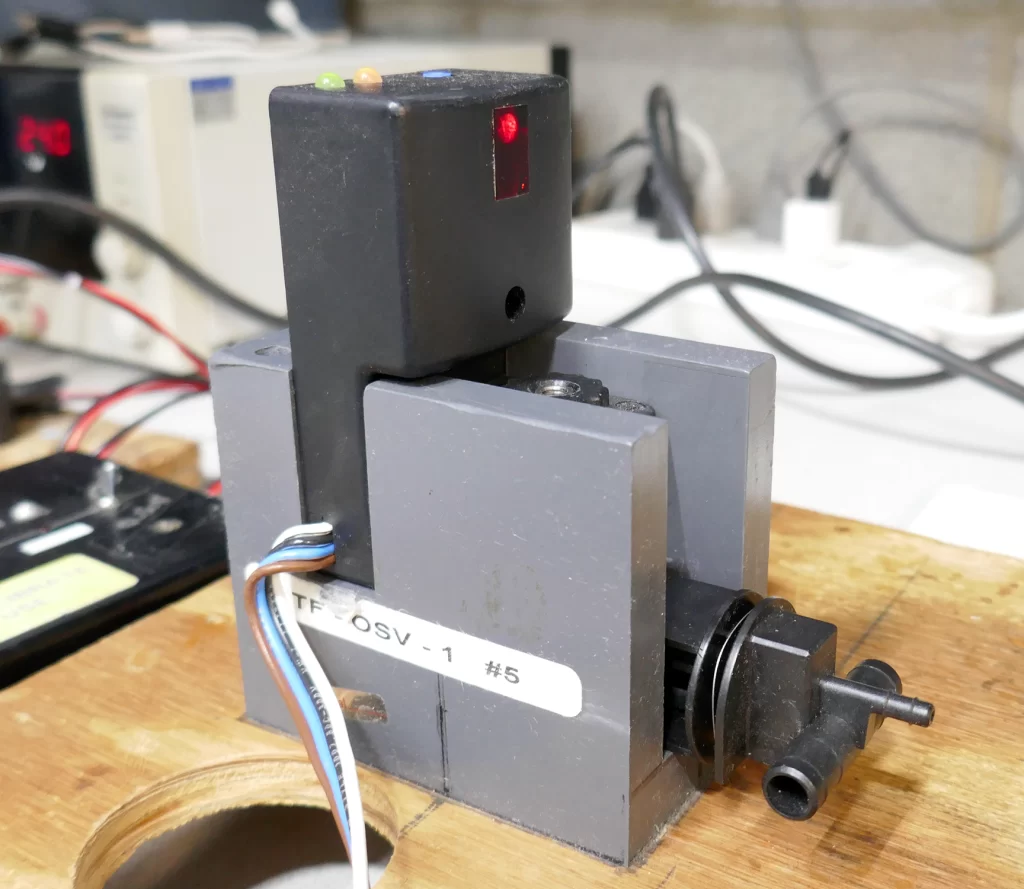

Canfield Connector then partnered with Spartan Scientific, a division of Canfield Industries, to produce this optical sensor and valve combination that would be named the OSV, Optical Sensor Valve.

Spartan Scientific used their design team to develop a custom valve body that allowed the entire device to mate with the electronics and again attach to the customers conveyer. The team at Spartan designed an innovative solution for the OSV that also allowed the valve to mate with additional units downstream in order to ensure proper product flow all throughout the system.

How the OSV Works

The concept behind the OSV is a simple use of optics that trigger pneumatics.

The optical sensor sends a beam of light to a reflector up to six feet across the conveyer bed. Within the electronic circuit there is an adjustable dwell setting that allows the user to make adjustments to their specific requirements. This adjustment controls the length of time a package is permitted to sit in front of the optical sensor. Once the beam in broken and the dwell time is exceeded, the electronics control the pneumatic valve which then sends an air signal to the previous bed of the conveyer. This signal pneumatically raises the roller system off the drive unit by using small puck like cylinders, stopping the movement of any product in the previous zone.

A valuable component of this design is a hallmark for many of Canfield’s projects for their customers worldwide: a retrofittable design.

Making the OSV retrofittable to the customer’s product brought immense value in both time and cost. The customer was able to use existing hardware and also service and upgrade existing installations. Creating an easy to install product is a consistent win for those who are looking for a solution that works well with systems already in place.

A Product of Communication

The OSV was a result of careful collaboration between Canfield Connector and the customer, as well as collaboration with Spartan Scientific. This process required a deep commitment to listening to the needs of the conveyor belt manufacturer and to understand the intricacies of the problem. By beginning with a thorough assessment of the manufacturer’s operational requirements, the engineers at Canfield Connector were able to begin designing a solution that would marry innovation and practicality.

The OSV came as a result of intentional partnership between the team at Canfield Connector and the experts at Spartan Scientific.

This customer-centric approach led to a custom-built product to help this customer guarantee precise control of product by means of modern electronics control and valve technology.

Cutting edge advancements are moving our world forward in every way, especially in areas that may be behind the scenes for most of the population. When moving forward requires electronic control and valve technology, Canfield Connector and Spartan Scientific will work to bring the innovative solutions that a changing world requires.