Civil Service: Modernizing the Hydraulics in Dams and Locks

By Parveen Gupta, Director of Large Projects, and Milan Milunovic, Senior Application Development Engineer, Large Projects, Bosch Rexroth Corporation

Our current civil infrastructure is the product of decades of investment and management to serve the transportation and supply chain needs of communities and industries. While highways, roads, and bridges constitute a large proportion of infrastructure, other portions incorporate mechanical drive and control systems of substantial size and complexity.

Systems such as locks and dams for transportation, movable bridges, dams for hydroelectric power plants, and irrigation and flood control systems constitute the “moving parts” of our civil infrastructure. In the U.S., many of these systems were first engineered and built in the 1950s and 1960s.

There is now growing commitment to repairing and modernizing this infrastructure, backed by billions of dollars of federal investment approved in 2021. This investment includes expenditures allocated to these civil engineering “moving parts.”

Modernizing these systems will be a cross-discipline challenge of engineering, construction, and project management. A key part of the process will be selecting and integrating a new generation of drive and control systems that offer the performance, versatility, and smart Industry 4.0 capabilities needed to make this modernization productive and long lasting.

A key to modernization is integrating a new generation of drive and control systems into moving parts of the infrastructure.

Challenging infrastructure conditions

In a 2017 report from the American Society of Civil Engineers, U.S. inland waterways received a D grade. According to the report, 49% of vessels passing through 25,000 miles and 239 locks of U.S. inland waterways experienced delays as a result of poor age-related conditions, as most waterways have well exceeded their 50-year expected life spans.

When first constructed, these systems were state of the art, with large cylinders, pumps, piping, valves, and other components designed to move large, heavy structures with the most precise motion possible at the time. They had to be rugged and function partially or fully submerged in extreme outdoor temperatures, operating efficiently for 30 to 50 years with proper maintenance and management.

Failure to properly fund maintenance and equipment replacement has contributed to its degradation. However, one of the biggest issues is that much of this equipment is long past its intended life cycle; systems installed for 50-year life cycles are forced to operate for 70-80 years. This leads to costly make-do repairs and fabricating replacement parts for equipment that is no longer manufactured.

There are also environmental impacts. Breakdowns or outdated seals can result in hydraulic fluid leaks into sensitive waters, forcing locks and other equipment to be shut down until repairs can be made, which leads to backups in river traffic.

Older locks and gates on irrigation systems and canals lose excess amounts of water. Especially in regions like California with climate change-driven droughts, water conservation has become critical, and modernizing these systems is vital to help manage the impact of climate change.

The operating controls for many of these moving systems are also much more mechanical and manually controlled, often requiring more operators than would typically be used in industrial facilities using modern controls. The introduction of PLCs and digital drives, even for the largest moving systems, enables greater automation, increased backup systems, and easier operation with more efficiently sized staffs, especially since many operators who have worked these older systems are rapidly retiring.

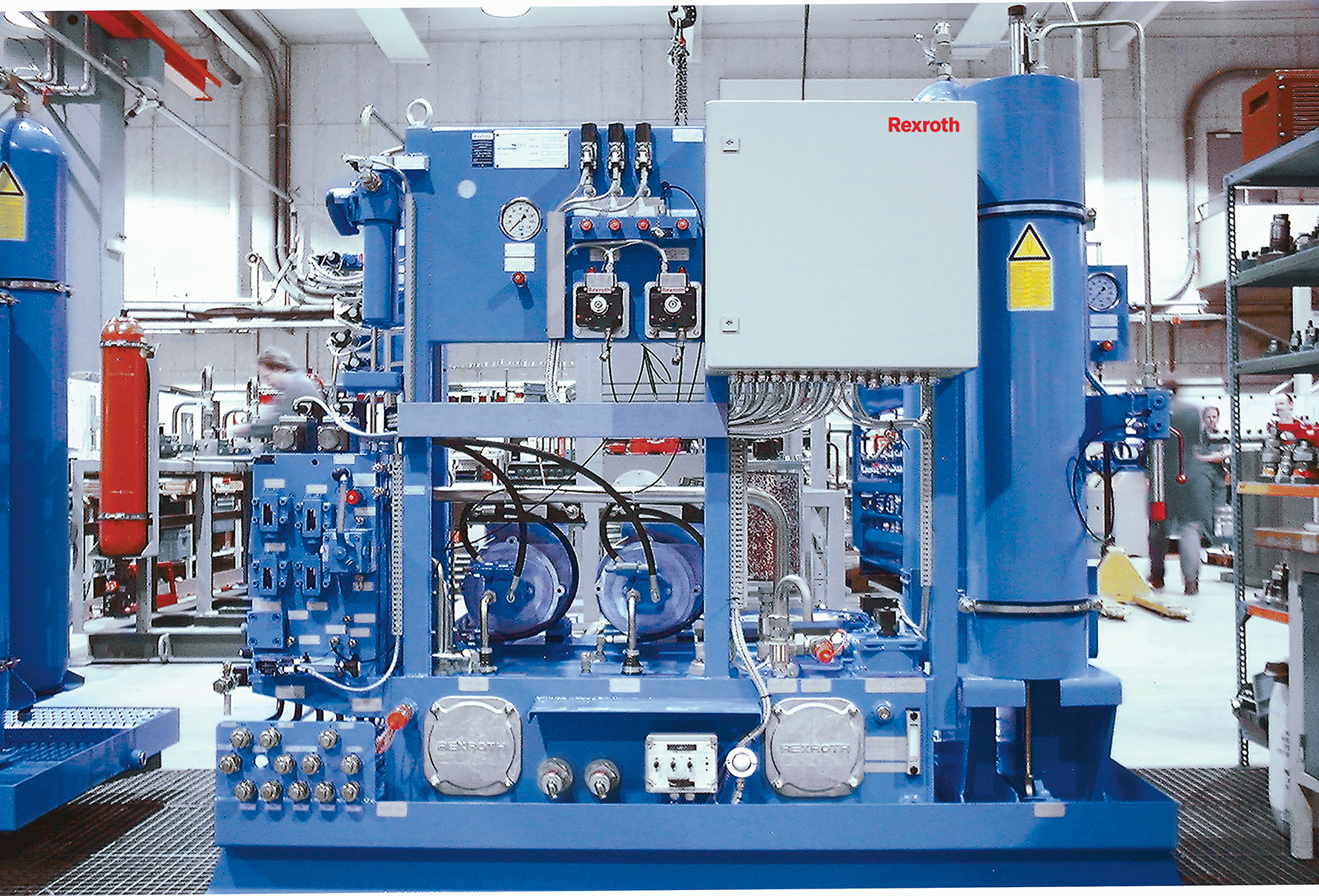

A hydraulic power unit on the Derinar Dam in Turkey.

New drive and control technologies

The goal of modernization should be to bring drive and control systems up to date so that infrastructure operators (and the customers who depend them) benefit from improved performance and reductions in delays for repairs, as well as full compliance with the latest safety and environmental regulations. Switching from older hydraulic systems to smarter, more efficient electrohydraulic technology can provide better performance in a smaller package, while reducing energy costs.

Locks on the La Yesca Dam in Mexico.

Hydraulic technology like large cylinders, pumps, and hydraulic direct drives and power units are now manufactured with greater precision and tolerances than the systems they are replacing. The older hydraulics systems typically operated within pressure ranges from 500 psi to peak rates of 1,000 psi.

Current hydraulic components are manufactured to tighter tolerances; 3,000 psi is the typical minimum, with higher pressure levels available, depending on the system. As a result, the hydraulic systems are much more compact while delivering significantly increased performance. A large hydraulic cylinder that needed to be 20 inches in diameter in the past can now be 10 inches, and the 6-inch pipe feeding it can be reduced to 2 inches.

This not only saves on space; since the system is more compact, it offers more precise motion control through the duty cycle, offering improved endpoint accuracy that can help make lock and dam operations more efficient and faster and help conserve water.

The latest drive technologies feature advances for improved life cycles. These include new, more durable piston-rod coating technology for hydraulic cylinders and the latest materials designed for optimal tribology with the goal of reducing wear and therefore maximizing lifetime.

The newest generation of hydraulic PLCs and smart drives gives infrastructure operators greater control and flexibility than existing controls platforms, some of which are decades out of date. They offer much more automation and remote-control capabilities, which is critical for installations that can spread out for acres.

As with other Industry 4.0 technologies, increased use of sensors, integrated with a new generation of electrohydraulic controls, supports advanced condition monitoring of all the drive and control equipment and enables predictive maintenance programs that identify potential problems early. This ensures that critical equipment shutdown and maintenance can be planned, and necessary repairs conducted well in advance, before serious damage and huge expense occurs.

The new technologies also give infrastructure operators greater freedom to staff repair and maintenance teams on a regional basis, rather than placing personnel at every location, since the modernized technology operates with much greater reliability. Predictive maintenance programs make scheduling work crews more efficient.

Systems engineering single-source approach

Selecting the new drive and control systems for a 70-year-old lock and dam system can be time consuming, particularly if it involves multiple suppliers. There are advantages to working with one provider who can supply all the latest hydraulics technology and digital controls, as well as support the integration of the complete solution.

For example, Bosch Rexroth provided a full suite of hydraulic drives and controls as well as complete integration services for constructing the Olmsted Locks on the Ohio River near Paducah, Kentucky, 10 miles upstream from the confluence of the Ohio and Mississippi Rivers.

For a five-year period, Bosch Rexroth was fully involved in providing hydraulic drives and controls for the five gates on the lock. The complete solution encompassed six hydraulic power units, ten Tainter-gate cylinders, multiple custom manifolds and control systems for the hydraulics, and the field piping. The company was also responsible for startup and commissioning, engineering and installing the piping, sensors, and wiring to make the gate drives fully operational, as well as training on the new systems.

This approach helped simplify the project for the Olmsted Locks general contractor, who was mainly responsible for the more massive concrete and steel construction of the project. Also, since Bosch Rexroth possessed in-depth expertise from similar projects in Europe and the Panama Canal, the Olmsted Locks team drew on their experience to keep the project on track.

With society’s renewed commitment to infrastructure modernization, the latest generation of drive and controls systems can be realized. The right technology, carefully selected to meet the unique demands of each installation, can help protect the environment, conserve water, reduce transportation delays, and ultimately provide a renewed and more productive transportation system.