Concrete Truck Hydrostatic System Overheats When Carrying a Full Load

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

When I had my hydraulic repair shop several years ago, we would rebuild hydrostatic pumps and motors for a local concrete company. They had a fleet of 15 or so concrete trucks that supplied the local contractors with their ready-mix concrete needs.

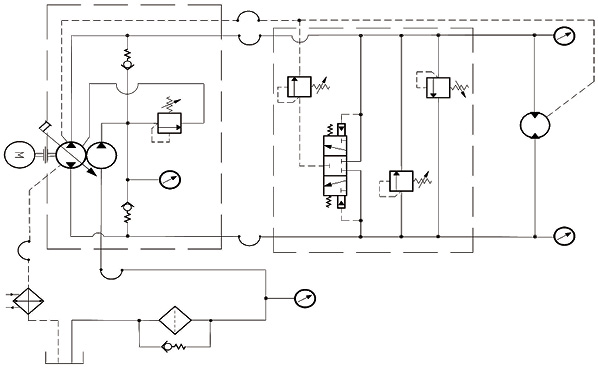

From time to time they would order just the gear type charge pumps for the main pump, but with a larger displacement. I inquired as to why they just needed these charge pumps and not the complete hydrostatic pump. They would tell me that the pump was slow to respond from a drop in the charge pressure. The attached circuit is the original used on the trucks.

One of the truck drivers complained to the owner that some of the trucks hydraulic systems were overly hot when they carried a full load. For some reason, he felt that the larger displacement gear pumps we were supplying must be causing the problem. He insisted that we should look at supplying them with a different brand of pump that would not cause the overheating problem.

The gear pumps were the same brand as the original unit and we were supplying new pumps except with a larger displacement.

Any idea what was causing the overheating problem?

See the Solution

The reason the larger charge pumps were needed on the concrete trucks was due to increased leakage in the warn pumps and motors. Adding a larger charge pump resolved the low charge pump pressure, but increased the leakage amount as well as the excess GPM dumping over the charge relief valve. Putting larger charge pumps just covered up the real problem of the pumps and motors having excessive leakage to their case.