Developing a Liquid Piston Gas Compressor/Expander for CAES and CO2 Sequestration

This column will bring you the progress of the pre-competitive research being conducted at member universities that are part of the CCEFP network. This research will help give insight into the future direction of fluid power.

The Center for Compact and Efficient Fluid Power (CCEFP) holds a monthly forum, highlighting research, workforce, and special topic presentations.

CCEFP is a network of fluid-power-research laboratories, academic faculty, graduate and undergraduate students at nine universities. It is also a National Science Foundation Research Center. For more information on CCEFP, visit www.ccefp.org.

Since 2014, the National Fluid Power Association (NFPA) Foundation has supported and is helping to expand the pre-competitive fluid-power-research activities of the CCEFP, dramatically increasing the number of institutions and students impacted by its research program. For more on NFPA, visit www.nfpa.com/aboutnfpa/missionfocus.aspx.

[hr-strip]

PURPOSE

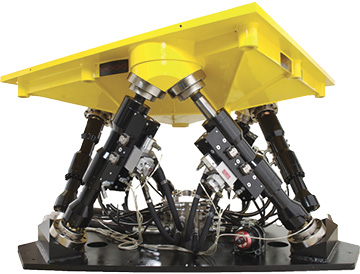

The goal of Perry Li’s project is to develop a prototype of a reciprocating high pressure (~200bar), high efficiency, liquid piston gas compressor within 18 months of the September 2018 start date. The prototype could be used for projects related to industrial gas preparation, grid scale Compressed Air Energy Storage (CAES), and carbon dioxide for sequestration or reuse.

Due to global climate change, there’s been a significant shift toward renewable energy. However, not all renewable energy is consistent, creating a dilemma for energy suppliers. To address the abundant, but intermittent challenges of renewable sources, companies often rely on “non-renewable” plants that supplement the energy supply from renewable sources during peak demand. The team is aiming to develop a grid scale energy storage device to replace peaker plants that will increase revenue and stabilize electrical grid frequency.

PROGRESS

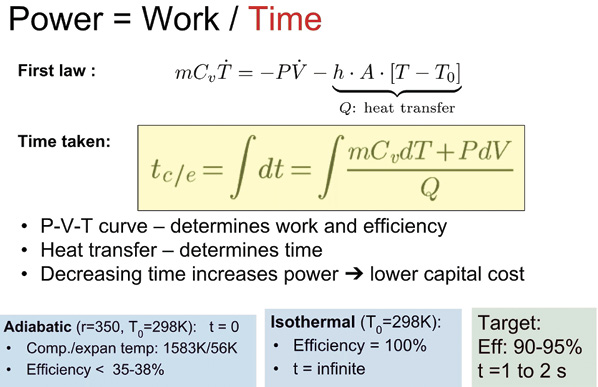

The process of creating an air compression/expansion component is met with the challenge of how to address energy loss. The team tackled the isothermal emissions as an attempt to reduce energy loss and were met with positive results. To increase this power expansion significantly the team learned that they needed to increase the heat transfer, using a modified version of the first law of thermodynamics.

Li and his team discovered that with the use of liquid piston compressor/expander with porous media, you can increase the heat transfer rate. This liquid piston compressor/expander allows the device to make heat transfer more efficient and piston trajectory more controllable.

When comparing the effect of porous media, the team reviewed the system with various sizes of the liquid piston compressor/expander chamber. During the tests, adjustments to the distribution of heat transfer in porous media, the shape of the chamber, and the flow trajectories dramatically affected the performance and efficiency, supporting the team’s original strategy.

In a realistic heat transfer model, the optimal flow can be adjusted over time, leaving an improvement in power density three times more efficient than before. Several tests demonstrated a consistent increase of 92% efficiency across multiple cases adjusting porosity, flow rate, and chamber design.

NEXT STEPS

The plan moving forward is to make the liquid piston gas compressor/expander more operable by developing a prototype that can be reusable. The team’s target is a 5kW prototype design with a compression time of 1-2 seconds. To do this, Li and his team will focus on valve design, liquid piston sensing and control, and dead-volume management.