Don’t Drain Your Profits: Remove Compressed Air Condensate Efficiently

Your air compressor makes more than compressed air. In the process of squeezing atmospheric air into compressed air, heat and water are produced. The compressed air coming out of the compression element is very hot and totally saturated with water vapor. If this water vapor is not removed, it will condense, causing water contamination as the air cools in the pipes and hoses in the plant.

On a hot summer day, say 90°F with 80% relative humidity, a 50-hp compressor delivering 200 cfm of compressed air at 100°F squeezes 2.1 gallons of water per hour from the atmospheric air, or more than enough to fill a 40-gallon drum per day. On a cooler day, say 70°F and 70% relative humidity, the compressor produces only 0.6 gallons of condensed water per hour due to drier conditions. On an even cooler day, perhaps 35°F, only about 0.2 gallons per hour of water will saturate out—or ten times less than the worst-case conditions. The system moisture loading is variable and depends on the ambient conditions.

If the ambient temperature of the plant is lower than the 100-degree discharge, let’s say 70°F, then another 0.36 gallons per hour of water will saturate out as the compressed air cools if the air is not dried somehow. This water will collect in low spots in the system and will pick up rust, dirt, and lubricant, forming an ugly brown mixture that will contaminate downstream processes and equipment. Worst-case scenario would be the contamination of a final product, such as a food source or moisture-sensitive chemical.

To prevent water from causing problems, some of the moisture is removed by air dryers that reduce the dew point of the pressurized air to levels much lower than the lowest ambient conditions. Typical general drying reduces the dew point to about 40°F using refrigerated air dryers. For a dryer sized for a 200-cfm compressor, this type of dryer would remove about 0.5 gallons of water per hour from a 100°F stream of saturated air. Desiccant dryers could be used if the compressed air pipes are exposed to very cold ambient conditions or if the process being supplied is very sensitive to moisture. To dry the air down to -40°F dew point from +40°F conditions, only 0.07 gallons of additional water per hour must be removed.

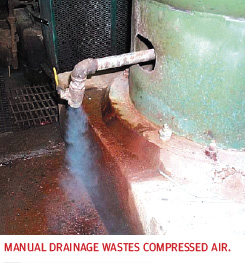

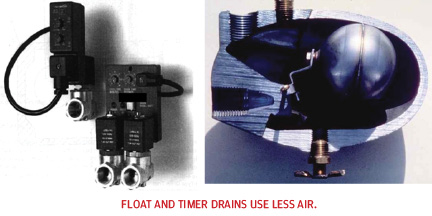

If all this condensed water were left to collect inside the system volume, the receivers and pipes would eventually fill up. There needs to be a way to drain away the condensate and because the flow of the drainage is variable, the drainage must be set to a rate high enough to cover the worst-case conditions, even though these conditions may only occur one or two times per year.

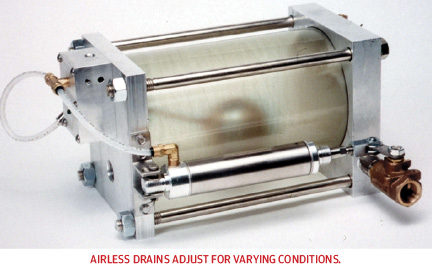

There are numerous ways to accomplish condensate drainage. The simplest, but most expensive, way is to simply crack open the drain at each condensate accumulation point. This leaks an expensive flow of compressed air in all conditions, as the flow doesn’t vary with moisture loading. Draining 10 cfm of air at a manual drain would cost about $2,200 per year at typical power costs of $0.10 per kWh. If this drain were fitted with a timer solenoid set at a fixed 20% duty cycle, the cost would reduce to $440 per year, but again the duty cycle does not vary with demand. Fitting the drain with an airless drain would reduce the annual electrical operating cost to near zero and provide automatic adjustment through varying ambient conditions.

All drains must be maintained to ensure proper operation, but which are the most important? In consulting with previously calculated water content, it can be seen that 80% of the water needs to be removed at the compressor separator, with the remaining amount being removed at the dryer. Thus, care should be taken to ensure adequate drainage at this important point. If the compressor drains fail, the condensate will make its way to the air dryer. Air dryers are not designed to handle free water, so therefore the dryer will be overwhelmed, causing moisture problems downstream.

It is very common to see additional drains installed to prevent moisture problems caused by a failed upstream drain. The more drains installed, the higher the system loading and the more condensate the compressor produces. Installing additional drainage can produce negative results and higher operating costs. Proper drain installation, maintenance, and testing are the keys to trouble-free operations.