Improving Energy Efficiency In Industrial Applications

The high cost of energy has placed a premium on finding ways to reduce the energy consumption by equipment and systems in industrial applications. In any industrial facility, there are multiple places to look for energy-saving opportunities.

Electric Motors

Electric motor-driven systems are estimated to consume more than one half of all electricity in the U.S. and more than 70% of all electricity in manufacturing applications. If you are looking to improve the energy efficiency of your operation, the first place you should evaluate is the motors. The initial purchase price of a motor represents only 2% of its total lifetime cost, while power usage represents almost all of the remaining 98%. It has been estimated that an energy management program that upgrades electric motors to more energy-efficient models can result in approximately 13% energy savings.

Motors that meet specifications established by the NEMA Premium® program are available from most manufacturers and will optimize efficiency, reduce power consumption, and improve system reliability. A relatively small upfront investment will pay back quickly and also pay dividends in energy savings for years to come. The savings are so significant that it can be worthwhile to replace fully serviceable, standard-efficiency motors.

Additionally, NEMA Premium motors are made to higher manufacturing standards, which typically result in longer life, less maintenance, and reduced downtime.

It’s also important to know if a particular motor is the proper size for its application. A motor that is too large for the job wastes energy and costs extra money to operate. To help in this analysis, suppliers of AC and DC motors publish straightforward sizing procedures to ensure that a motor is properly sized for optimum energy efficiency.

A well-planned energy management program, coupled with proper motor maintenance, can reduce operating expenses and increase profits. Proper motor maintenance will enhance efficiencies and prolong a motor’s life.

Items to check during inspection:

- Old or inadequate lubrication

- Vibration

- Improper ventilation causing overheating

- The presence of dirt or other contaminants

- Motor and load misalignment

- Wide variation in load conditions

- Worn belts, sheaves, and couplings

- Loose hold-down bolts

Gear Reducer Options

Substantial energy and operating cost savings are gained by combining premium efficient motors with highly efficient gearing. Your choice of gearing can have a significant impact on energy usage. Gearing is a common method of speed reduction and torque multiplication; however, during this process the gearing consumes a certain percentage of power. Obviously, as power losses are reduced or minimized, efficiency improves.

Worm gearing, for example, is widely used in industry. Worm gears are generally compact and economical, but not your best choice for energy efficiency. There is a lot of friction caused by the worm gear design and at high ratios this can cause the reducer to be only (approximately) 50% energy efficient.

Helical gear reducers are commonly found, as well. But when concerned with optimizing efficiencies, helical gearing is a better choice than worm gearing, offering a significantly higher efficiency at 98% per reduction. Helical gears are popular because they are durable and quieter, even at higher speeds.

Belt Selection and Maintenance

Properly designed belt transmission systems are highly efficient and quiet. However, they require periodic maintenance to ensure efficient operation. In addition, certain types of belts are more efficient than others.

V-belts are used in the majority of belt drives. These belts have a trapezoidal cross section that wedges into pulleys to increase friction and power transfer capability. In operation, v-belt efficiency can deteriorate by as much as 5% over time if the belt is not periodically re-tensioned, as under-tensioned belts lead to slippage and reduced power transfer efficiency.

Cogged belts have slots that run perpendicular to the belt length. These slots reduce belt-bending resistance and allow the belts to be used with v-belt pulleys. Cogged belts run cooler, last longer, and are about 2% more efficient than standard v-belts. Therefore, cogged belts should be considered as replacements for v-belts wherever possible.

Synchronous belts have teeth and require the installation of mating toothed drive sprockets. These belts are about 98% efficient and maintain that efficiency over a wide load range. Synchronous belts require less maintenance and retensioning, operate in wet and oily environments, and run slip-free.

However, while synchronous belts are extremely efficient, cogged belts may be a better choice when vibration damping is needed or shock loads cause abrupt torque changes that could shear a synchronous belt’s teeth. Synchronous belts also make a whirring noise that might be objectionable in some applications.

Additionally, proper belt alignment and tensioning are critical to ensure efficient operation. Improper tensioning leads to inefficient power transmission, belt failure, and associated costs. If a belt is not running at optimum tension, it is wasting energy and money. Manufacturers offer a variety of tools that help ensure the proper installation of belt drives, including alignment tools and tension guides.

Another maintenance concern and efficiency loss is sheave wear. Misalignment and improper belt tensioning can cause excessive wear on sheaves. When sheaves wear, a formerly flat groove sidewall takes on a concave shape, and the surface that interacts with the belt is compromised. Eroded sheave sidewalls can cause up to 12% loss in v-belt drive efficiency; rough, worn sidewalls can reduce belt life by up to 50%. Belt manufacturers offer sheave gauges to help assess the condition of the sheave wall and make good decisions regarding replacement.

Variable-Frequency Drives

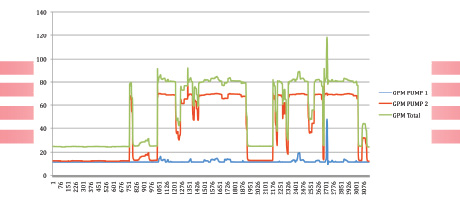

Variable-frequency drives (VFDs) have long been known to save energy, specifically in pump and fan applications. In fact, studies have shown the payback period is often less than one year.

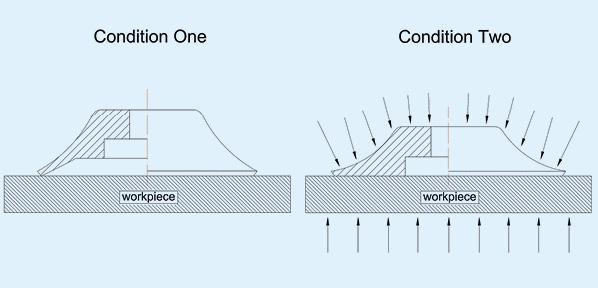

In most facilities, pumps and fans run at constant speeds, and flow rates are adjusted by automatic valves or other mechanical means. This can be highly inefficient because motors running at constant speed always consume the maximum amount of energy, even during periods when lower speed operation would suffice.

VFDs provide more efficient operation by regulating motor speed– and therefore flow rate–electronically in response to changing operating conditions.

In addition, VFDs can be used to improve process control. If a plant uses constant-speed motors to run conveyors on the line, it either must run without material during the time required to change temperature in a heat zone or produce scrap during this period.

When using a VFD, the time needed to change speed is significantly less than the time it takes to change heat-zone temperature. By adjusting the material flow continuously to match heat zone conditions, a plant can operate continuously. The results are decreased energy usage and less scrap.

For more information: Applied Industrial Technologies is a leading industrial distributor that offers more than four million parts to serve the needs of MRO and OEM customers in virtually every industry. Applied® provides engineering, design, and systems integration for industrial and fluid power applications, as well as customized mechanical, fabricated rubber, and fluid power shop services. Applied also offers maintenance training and inventory management solutions that provide added value to its customers. Visit www.Applied.com.