Efficiently Comparing Filtration Media

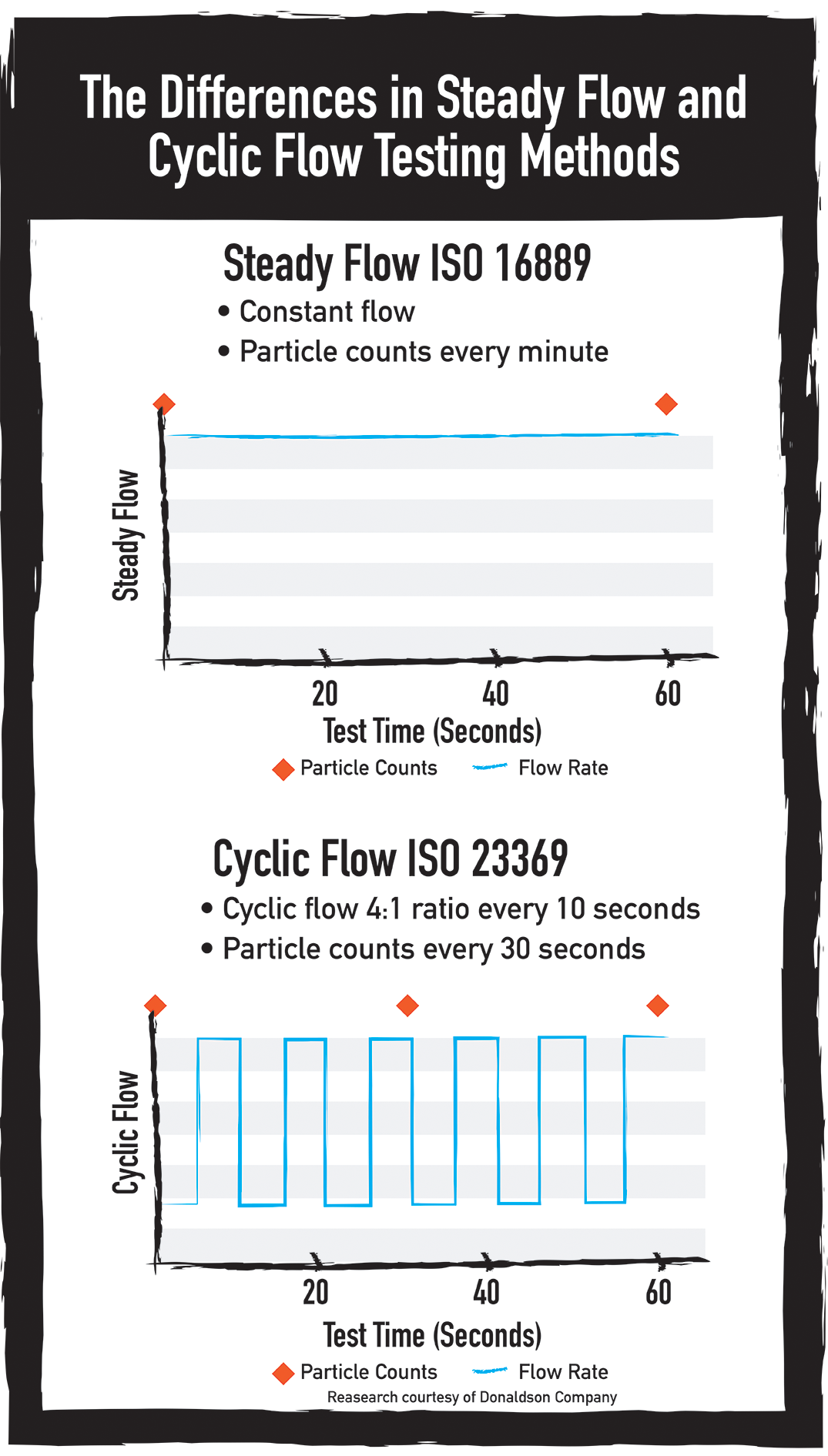

Not all hydraulic filters are created equal, and neither are the testing practices that helped create them. The international standard ISO 16889 used to be the final word in hydraulic filtration testing. This multipass method was an accepted way to evaluate a filter’s performance. The method required filters to only be tested under steady flow conditions.

Not all hydraulic filters are created equal, and neither are the testing practices that helped create them. The international standard ISO 16889 used to be the final word in hydraulic filtration testing. This multipass method was an accepted way to evaluate a filter’s performance. The method required filters to only be tested under steady flow conditions.

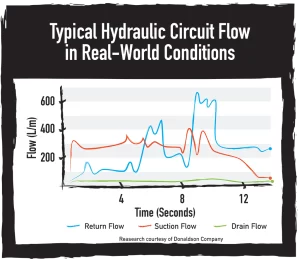

As anyone who has operated hydraulic equipment knows, steady flow conditions are a rarity. Hydraulics regularly operate under conditions of cyclic flow, meaning that pressures and flows fluctuate, causing contaminants to dislodge from filter media and re-enter the system, where they cause wear, drops in performance, component failure, and eventually unscheduled downtime of equipment and vehicles.

Because real-world conditions do not reflect the conditions dictated under ISO 16889, in 2021 a new standard, ISO 23369, was introduced as a multipass method of evaluating filtration performance in cyclic flow conditions. Both standards were then used to test hydraulic filter efficiency; whereas ISO 16889 provides a “beta” efficiency value, ISO 23369 provides an alpha efficiency.

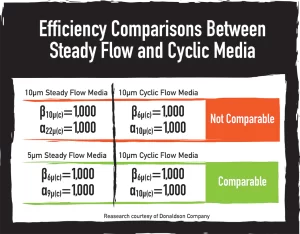

Both methods of testing and media have merit. However, there are now two methods for testing hydraulic filter efficiency and media built to meet the older beta efficiency, which cannot be adequately compared to media built to meet the new standard, which uses alpha efficiency.

Both methods of testing and media have merit. However, there are now two methods for testing hydraulic filter efficiency and media built to meet the older beta efficiency, which cannot be adequately compared to media built to meet the new standard, which uses alpha efficiency.

New media for new standards

Cyclic flow conditions are nearly always present in mobile hydraulic applications. This makes the cyclic flow test lend itself to being a better representation of the environment to which hydraulic filters are exposed. The media developed to meet these standards offer better protection of hydraulic components.

Cyclic flow testing and alpha efficiency ratings are new to the industry, so it can be confusing when cyclic media and legacy synthetic media are compared.

Cyclic flow testing and alpha efficiency ratings are new to the industry, so it can be confusing when cyclic media and legacy synthetic media are compared.

Legacy synthetic media are prone to releasing contaminants under cyclic conditions, driving the need to develop new media that perform under these conditions. New technology like the fine-fiber Alpha-Web media designed by the Donaldson Company to perform to ISO 23369 are essentially in a different category than previous synthetic media.

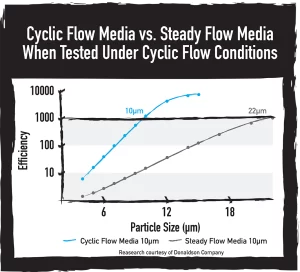

It seems logical to compare efficiencies and initial pressure drop performance data for cyclic and steady flow media. For example, cyclic flow 10µ media and a traditional 10µ synthetic media have the same 10µ efficiency rating. However, the traditional 10µ synthetic media has an efficiency rating based on steady flow testing of ISO 16889. When testing traditional synthetic 10µ media under the cyclic flow test conditions of ISO 23369, this type of media only delivers 22µ efficiency.

This leads to the conclusion that before a comparison with a legacy media’s performance with a cyclic flow media’s performance, it must be assured that the comparison is between equal alpha efficiencies. In the example above, the efficiencies of the legacy and cyclic flow media are too far apart to be comparable.

This leads to the conclusion that before a comparison with a legacy media’s performance with a cyclic flow media’s performance, it must be assured that the comparison is between equal alpha efficiencies. In the example above, the efficiencies of the legacy and cyclic flow media are too far apart to be comparable.

Instead, comparison is needed between two media that have equivalent alpha efficiencies. When testing a 10µ cyclic media under the steady flow method of ISO 16889, it delivers an efficiency of 6µ, compared with a legacy media that also has a cyclic efficiency at similar micron rating. For example, legacy media with 5µ beta efficiency and 9µ alpha efficiency can be compared to the cyclic flow media because the efficiencies are very similar. This is a key factor in comparing pressure drop ratings.

Media restrictions

Media restrictions

In a hydraulic system, as oil flows across a filter, flow is restricted, causing a reduction in pressure or pressure drop. In general practice, the more efficient a filter is, the higher its pressure drop. However, it must be noted that it is not always simple or direct.

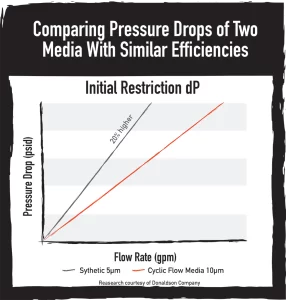

Simply comparing pressure drop ratings between a 10µ legacy media and fine-fiber cyclic media shows that the legacy media’s pressure drop is 20% lower than the cyclic flow media. On the surface, it seems that the legacy media has a more desirable pressure drop performance.

When media are similarly efficient under cyclic flows, you can accurately compare pressure drop performance. Returning to the previous example, 10µ cyclic flow media and 5µ legacy synthetic media have been proven comparable in efficiency performance.

It is revealed, then, that 10µ cyclic flow media actually shows a pressure drop 20% lower than 5µ legacy media. In situations requiring high efficiency but where restriction is a concern, the cyclic flow media is the clear winner.

Before comparing the performance of different hydraulic filtration media, you must determine if they can be compared. Failure to ascertain the true efficiency of legacy media versus cyclic flow media can lead to filtration decisions that are anything but efficient for your bottom line.