Bucket Truck Idle Reduction for PG&E

By Jill Santos, Marketing Director, Duryea Technologies

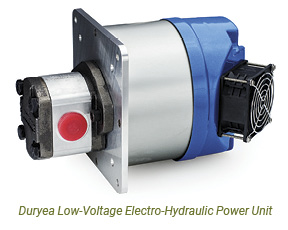

Duryea supplied the right BLDC electro-hydraulic motor solution for Pacific Gas and Electric’s Hybrid Fleet Program.

The Problem

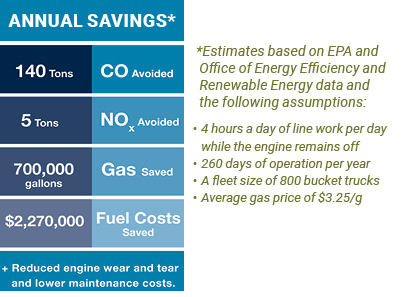

In conventional utility service trucks, the buckets, outriggers, and other accessory loads require power from a parked vehicle’s engine for an average of 4-5 hours per day while workers maintain power lines. The remainder of operational hours are typically spent on the road.

According to the EPA, a work vehicle with a weight classification of 7-8 tons will emit an average of 5.5 grams of NOx and 152 grams of CO per hour,1 as well as consume 0.85 gallons of fuel per hour while idling.2

This issue is especially critical in California, where, in addition to having stringent air quality standards, fuel prices are consistently amongst the nation’s highest.3

PG&E, one of the nation’s largest utilities, has invested in new solutions to help its California fleets reduce emissions4 and operating costs. Its initial efforts included procurement of over 800 hybrid bucket trucks sourced from a major commercial work truck OEM and built to its specifications.

The Challenge

In the hybrid fleet, an electro-hydraulic power unit must efficiently power the truck’s accessory loads while the engine remains off during power line work.

To prevent quick depletion of the low-voltage LiFePO4 battery pack, careful selection of the motor for the electro-hydraulic power unit was critical.

The Solution

The OEM’s hybrid system packager chose a Duryea SolidSlot® Triple Stack 36V motor with integrated Duryea electronics coupled to an industry-standard 7cc SAE A 2 Bolt 5/8-9T spline gear pump. This yielded the most efficient and power-dense electro-hydraulic power unit available for the application.

Same Hydraulic Performance, Less Fuel

36V SolidSlot Triple Stack BLDC Motor with Pump

Duryea designed its line of SolidSlot brushless motors to maximize performance at low voltage. These motors are field-proven for idle-reduction and other battery-powered applications. The winding-free stator architecture is durable and efficient.

- 36V nominal, 270A

- 11.3kW (15HP)

- Flow up to 8pgm

- Pressure up to 3,000psi

- 36V (4,000rpm)

- 24V (2,700rpm)

- 12V (1,300rpm)

- Operated at 42V, 24V, and 12V with LiFePO4 battery

- 8 gpm

Other Standard Options Available or Engineered-to-Order

Visit www.duryeatechnologies.com or call 484-277-7137 for more information.

SOURCES

- United States Environmental Protection, Office of Transportation and Air Quality, EPA420-F-08-025 Agency Idling Vehicle Emissions for Passenger Cars, Light-Duty Trucks, and Heavy-Duty Trucks Emission Facts, October 2008, https://nepis.epa.gov

- Office of Energy Efficiency and Renewable Energy, Fact#861 Idle Fuel Consumption for Selected Gasoline and Diesel Vehicles, February 2015, https://www.energy.gov/eere/vehicles/fact-861-february-23-2015-idle-fuel-consumption-selected-gasoline-and-diesel-vehicles

- Shelbi Austin, U.S. News and World Report, The 10 States With the Highest Average Gas Prices, https://www.usnews.com/news/best-states/articles/2018-06-20/the-10-states-with-the-highest-average-gas-prices

- PG&E Greening Vehicles, https://www.pge.com/mybusiness/environment/pge/fleets/

Excellent and A wonderful read! Your article is the best one I have learnt, and it has helped me. Keep doing that.