Electrohydraulics: On the Road to Zero

.By Miguel Onandia, Electro-Mobility & Services Sales Manager, Poclain.

.By Miguel Onandia, Electro-Mobility & Services Sales Manager, Poclain.

The off-highway equipment market is undergoing a strong zero-emission trend in line with increasing regulatory, political, environmental, and societal pressure at local and global levels. This trend will accelerate in the upcoming decades on all continents. The small off-road machinery segment will be particularly impacted in terms of penetration. It is comprised of machines with a total power lower than 19 kW, with two-, three-, or four-wheel drive configurations and with traction and auxiliary functions. These include, for example, mini-wheel loaders, mini-site dumpers, truck-mounted forklifts, or light tandem compactors.

On the end-user side, the needs related to small machines are going to evolve to include:

• zero emissions on-site,

• low noise pollution for both operator and on-site,

• the same performance as machines with internal combustion engines,

• sufficient operational range in hours per day,

• increased safety to use and maintain, and

• improved total cost of ownership compared to machines with internal combustion engines.

To address these evolutions in the small-machinery segment, machine manufacturers are developing and producing more emission-free machines. Versions with internal combustion engines will cohabit with versions without an engine in assembly factories, either sharing the same machine platform (the current one with internal combustion engine) or using dedicated ones. The breakdown of numbers between all versions will vary over time, depending on applications, markets, and internal factors. This evolving market situation requires versatile development strategies for the machine manufacturers.

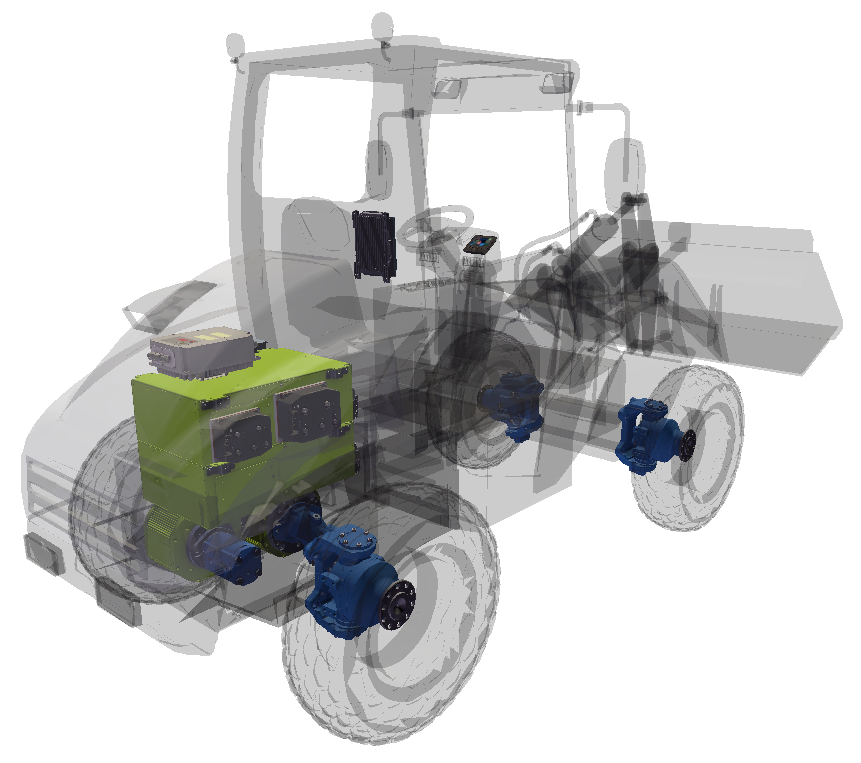

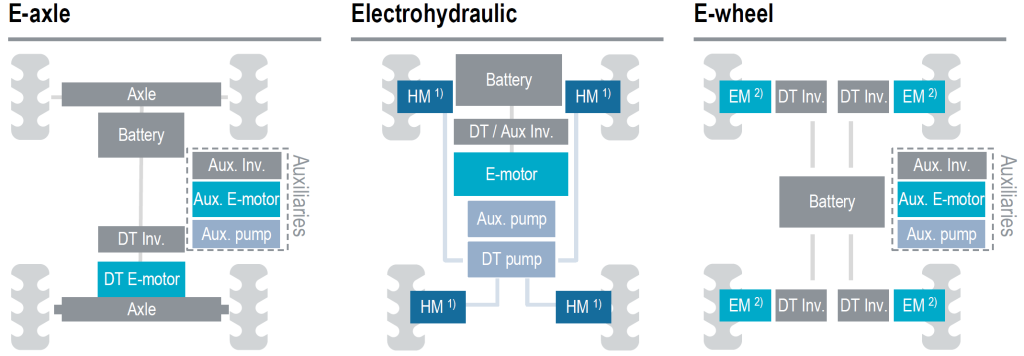

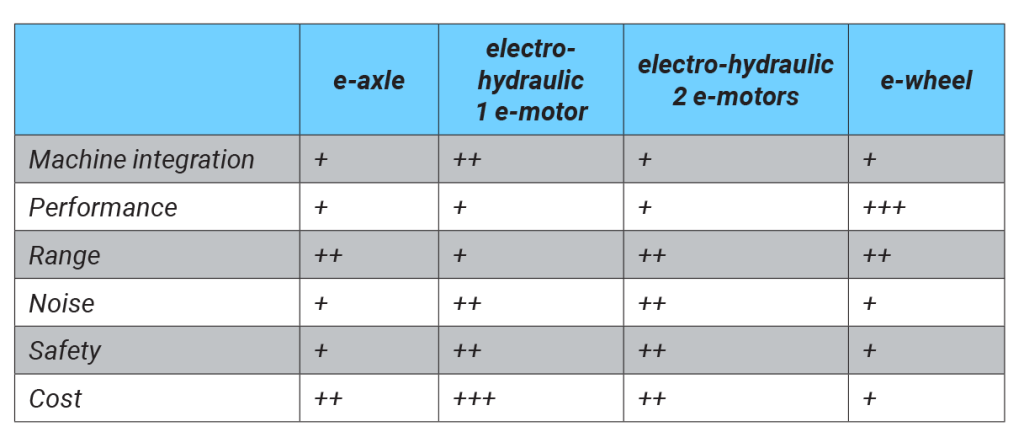

When developing zero-emission off-road equipment, various technologies are possible for consideration. This article considers and evaluates three technologies: electrified axle (e-axle), electrohydraulic with hydraulic wheel motors, and electric wheel motors (e-wheel). The decision for one solution or another can have a global impact on the purchasing, supply chain, R&D, industrialization, sales, aftermarket, and finance at machine manufacturers.

When developing zero-emission off-road equipment, various technologies are possible for consideration. This article considers and evaluates three technologies: electrified axle (e-axle), electrohydraulic with hydraulic wheel motors, and electric wheel motors (e-wheel). The decision for one solution or another can have a global impact on the purchasing, supply chain, R&D, industrialization, sales, aftermarket, and finance at machine manufacturers.

In terms of the components, e-axle and e-wheel technologies require multiple inverters and electric motors, while the electrohydraulic solution can use either single or multiple inverters and electric motors. In both cases, a strong knowledge base in inverter design, manufacturing, and embedded control software are key.

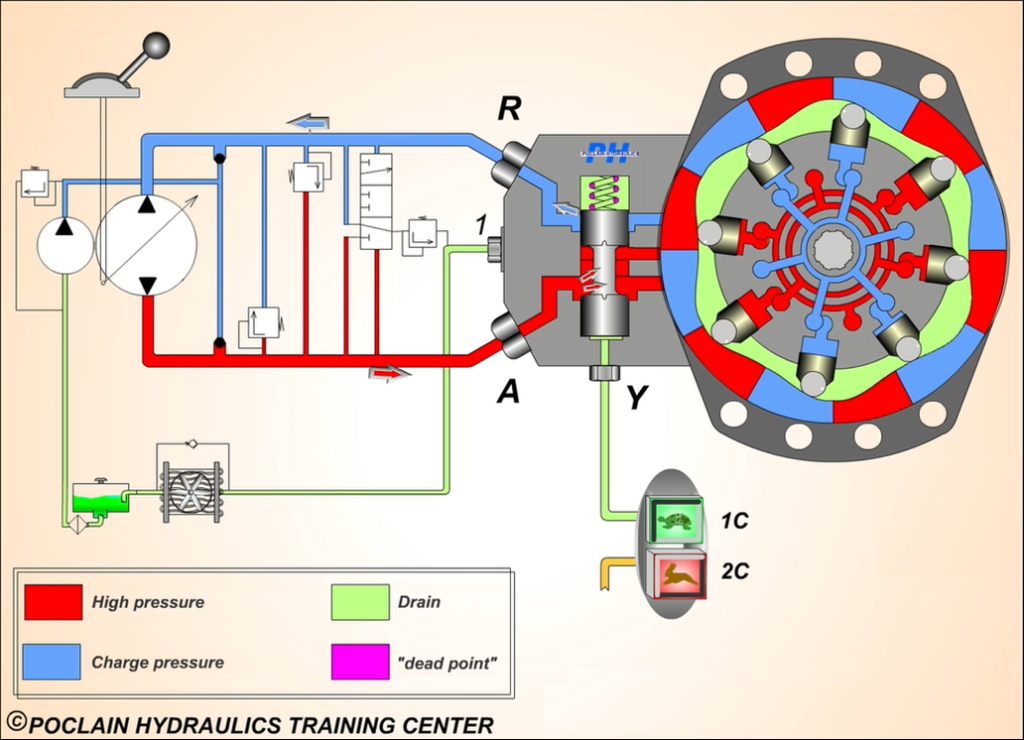

If we consider current machines fitted with an internal combustion engine and a hydrostatic transmission, the electrification technology that logically comes to mind first is the electrohydraulic one as particularly well suited to electrify these machines.

With electrohydraulic technology, different architectures are possible. Among them, we have:

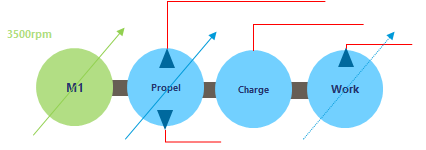

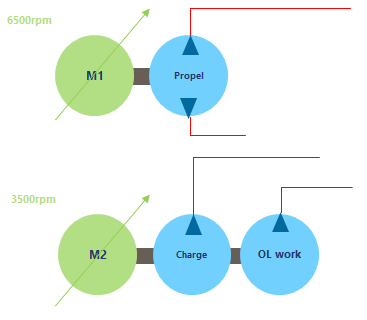

• Architectures with two separate electric motors, one for the propel function with a closed loop fixed displacement pump and the other for auxiliary functions with open loop pump. These architectures are used if the duty cycle and sizing show benefit in performance and efficiency.

• Architectures with one single electric motor, used for both the propel function with a closed loop variable displacement pump and auxiliary function with an open loop pump. These architectures are used if cost and commonality with the diesel version of the machine matter more.

Electrohydraulic transmissions provide a variable ratio, thanks to their multi-displacement hydraulic wheel motors and possibly their variable displacement pump. Moreover, electrohydraulics provides benefits in terms of control: the propel function uses a closed loop hydrostatic circuit allowing four-quadrant operation, regeneration while braking or driving downhill allows for range improvement, smart control and proper sizing allows for transmission optimization. Concerning safety, either in conditions of state of charge close to 100% or in conditions of negative cell temperatures, braking can be secured thanks to hydrostatic braking and emergency friction brakes available with electrohydraulic technology.

On the OEM side, no complete machine redesign is needed because mobile hydraulics remains and is combined with power electronics and a battery. This means that the electric machine development costs are lower because the project perimeters are smaller. In addition, the industrial investments are lower as well because the impact of electrification on the current assembly lines is smaller. Concerning the procurement flows and stocks, they are simplified by the high commonality of components between current diesel and new electrohydraulic machines. Therefore, electrohydraulic technology provides both cost efficiency and a shorter time to market than is usually possible for zero-emission machines.

On the machine users’ and owners’ side, electrohydraulic technology provides a series of benefits as well. Among others, users and owners include machine rental companies, construction, agricultural and industrial companies, and many others. The first benefit of electrohydraulics is the time-proven high ruggedness coming from its hydraulic core. Actually, mobile hydraulics has equipped off-road machines for decades and has acquired a high level of maturity over time. In a quickly evolving environment, high ruggedness and maturity are valuable for OEMs as well as for machine users and owners. Moreover, keeping the current mobile hydraulics allows them to achieve the same performance with the electrified machine as with the current diesel one. This advantage is key because a given machine must achieve a certain amount of work regardless of its energy source to ensure the required productivity and solve the economical equation.

On the machine users’ and owners’ side, electrohydraulic technology provides a series of benefits as well. Among others, users and owners include machine rental companies, construction, agricultural and industrial companies, and many others. The first benefit of electrohydraulics is the time-proven high ruggedness coming from its hydraulic core. Actually, mobile hydraulics has equipped off-road machines for decades and has acquired a high level of maturity over time. In a quickly evolving environment, high ruggedness and maturity are valuable for OEMs as well as for machine users and owners. Moreover, keeping the current mobile hydraulics allows them to achieve the same performance with the electrified machine as with the current diesel one. This advantage is key because a given machine must achieve a certain amount of work regardless of its energy source to ensure the required productivity and solve the economical equation.

If we look at the machine level, the comparative evaluation of the electrification technologies has to take into account various criteria simultaneously, including:

• Machine integration. The physical installation of the system on the machine (for example, the available space, ease of installation) and the contribution of the system to the machine control (for example, ergonomics, controls).

• Performance. What the machine does (for example, speed, load capacity, traction control).

• Range. Factors that impact the machine range in hours (for example, battery size, compromise between efficiency, and duty cycle).

• Noise. The noise level emitted by the machine (for example, hydraulics, gears).

• Safety. The safety of people who will interact with the machine in one way or another (for example, high voltage or current, battery regeneration limits).

• Cost. All costs related to the system lifecycle (for example, production, recycling).

The table below provides a comparative evaluation based on

these criteria.

Electrohydraulics is a versatile technology well suited for the electrification of current diesel machines, and it can be used for complete new electric machines. The technology allows OEMs to address market evolutions with reduced risks and provides solutions for every machine platform, whether pure diesel, diesel and electric, or pure electric.