Emerson Executive: The Journey to Sustainability

Improving pneumatic efficiency is a key step.

By Hakan Erdamar, Group President of Discrete & Industrial, Emerson.

People all over the globe are taking meaningful steps to reduce their environmental impact. I see it in my own life, in the importance of sustainability to my twin daughters, who are now 23. They grew up caring about the future of the earth, and I saw how much it mattered to them: their sad looks when we received a package with unnecessary packaging material and their scolding when someone threw something away in the wrong bin. For them, sustainability is a vital issue that should take priority in everyone’s life.

And my daughters are not alone. As we moved around the world, it was amazing to see firsthand how people prioritized sustainability. When we lived in Singapore, trash was a main concern, since there was limited landfill space. As a result, people developed innovative solutions to minimize garbage and convert it to fertilized water for plants. When we moved to Europe, it was clear that sustainability is rooted within the culture, and people work to preserve the natural environment. After we moved back to Asia, I witnessed attitudes shift from an urgency to modernize at all costs, including environmentally, to an urgency to create eco-friendly solutions.

This collective importance and focus on sustainability, of course, extends to the industrial sector. As the need to conserve resources and find environmentally responsible solutions grows ever more persistent, sustainability is one of the highest priorities for many companies. However, it will take solid execution plans and perseverance to cut global carbon emissions in half by 2030 and completely decarbonize by 2050 to limit global warming according to the Paris Agreement.

To achieve this, some companies, like Emerson, are shaping their purpose to create road maps to industrial sustainability. Using our expertise, technologies and solutions, we’re addressing environmental stewardship and responsibility in three primary ways: greening of, greening with, and greening by.

What exactly do we mean by greening of, greening with, and greening by? Greening of is how we improve our own internal environmental sustainability performance; greening with is how we foster collaboration among stakeholders through participation and partnership; and greening by is how we support and enable our customers’ decarbonization and environmental sustainability efforts through implementation of Emerson products, solutions, and expertise.

Using this proven, threefold framework, we’ve seen that we can reliably reach our environmental, social, and governance goals and create a healthier world when we work together.

Greening of

At Emerson, we’re working to improve our own internal sustainability performance through our policies, our approach to manufacturing, and our buildings. We’ve committed to reducing our greenhouse gas emission intensity by 20% by 2028, and we’re enlisting our energy providers, supply chain partners, and logistics services to support similar objectives.

To help ensure our commitment to sustainability touches everything we do, we’ve infused our management processes with this focus, including how we manage our facilities. For instance, we recently installed our advanced AVENTICS AF2 flow sensors on production equipment in some of our facilities, including our Slovakia plant that manufactures Branson products and our Sissach, Switzerland, plant to continuously monitor compressed air. As a result, we’ll see significant energy savings; at Sissach alone, the 19 AF2 sensors will reduce energy use by 20%, or $58,000 in compressed air savings and 68,000 kg of reduced carbon emissions over 10 years.

Some of our facilities are implementing renewable energy resources. Our new Mahindra World City facility in Chennai, India, will be generating approximately half of the plant energy from solar power. The New Jersey Department of Environmental Protection recognized our Florham Park ASCO facility for its sustainability measures and leadership in environmental stewardship.

Greening with

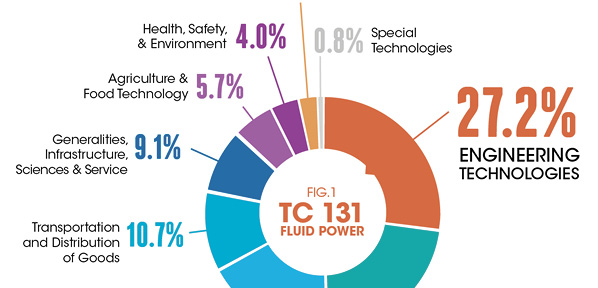

Fostering collaboration among stakeholders can happen in several meaningful ways locally and globally. It means participating in leading sustainability industry forums, partnering with institutions to drive sustainable innovation, and engaging with governments to support sustainability-related policies and regulations.

Through our partnerships, we help shape sustainability initiatives, boost sustainable projects, and help develop critical policies. One partnership that we’re particularly excited about is the European Clean Hydrogen Alliance. The ECHA was established in 2020 to accelerate industrial decarbonization in line with European Union climate change objectives. It brings together manufacturers, automation technology suppliers, public authorities, and other stakeholders to support Europe’s clean energy transition. As an alliance member, we’re bringing our innovative technologies and industry expertise to support hydrogen-sector projects, helping to achieve Europe’s goal of net-zero carbon emissions by 2050.

We’ve been involved in the hydrogen industry since its beginnings and have developed full capabilities across the global hydrogen value chain. Our experts have extensive knowledge regarding the unique needs of this extremely light and potentially explosive element. We understand what’s required to successfully build the infrastructure and the processes needed to make the transition to clean hydrogen, and we are supporting our customers in each stage as they scale up their production of clean hydrogen technologies. In our membership of the European Clean Hydrogen Alliance, we can share this knowledge as well as solutions specifically developed for clean hydrogen technology.

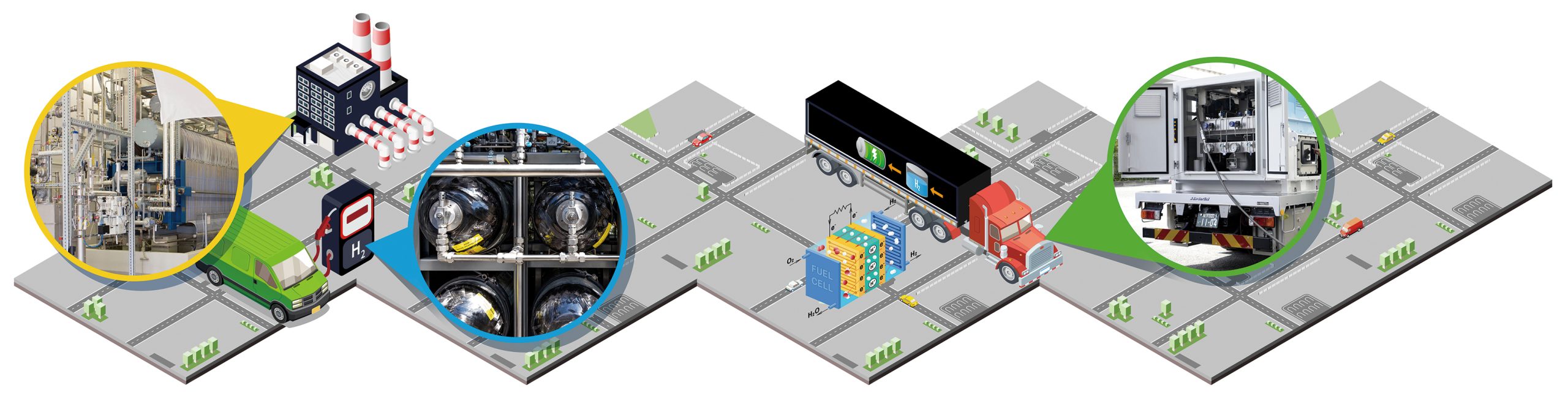

Some of these solutions are TESCOM and ASCO components used for fluid control processes throughout the hydrogen fuel value chain. To keep electrolyzer areas and hydrogen fueling stations safe, quick safety system shut-off valves are essential. The reliability of our TESCOM VA and VG Series safety shut-off valves has long been proven in the field, and our ASCO 290 Series pressure operated valves provide shut-off control of hydrogen, oxygen, and water in electrolyzer applications. Specifically designed to maximize fuel efficiency in industrial and commercial hydrogen fuel cell vehicles, our TESCOM HV-3500 Series hydrogen onboard regulator provides consistent pressure and continuous flow of hydrogen to the fuel cell in the full range of operating conditions while our ASCO 202 Series proportional valves can provide final control of hydrogen fuel before it’s delivered to the fuel cell.

As we make the transition to clean energy, it’s paramount that the pressure and flow control solutions used in electrolyzers, fuel cells found in hydrogen-powered vehicles, and hydrogen fuel dispensing stations are safe, reliable and efficient.

Greening by

Many companies may feel pressured to move quickly when working toward sustainability goals. While speed is critical, integrating proven solutions that can scale can ensure continued success.

Through greening by, we are delivering sustainable solutions and sharing valuable knowledge that can reliably improve our customers’ efficiency, reducing emissions and conserving resources, and supporting the development of sustainable technologies. The TESCOM valves and regulators used to reliably control pressure and flow in hydrogen fuel cells and electrolyzers are just some of the many sustainable technologies we’ve specifically developed to help decarbonize industries. Another is Emerson’s Branson ultrasonic metal welding. The technology can reliably bond thinner, more delicate metals such as advanced hybrid film materials, making it possible to produce smaller, lighter, and more energy-dense electric vehicle and energy storage system batteries.

Optimizing pneumatics

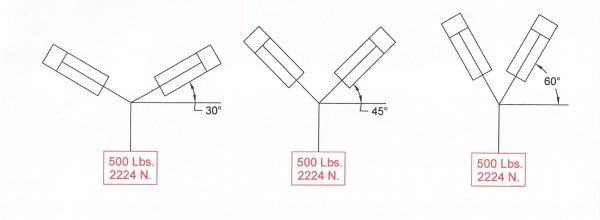

One key pneumatic device that our customers are using to improve energy efficiency and optimization is our AVENTICS Series AF2 flow sensor. Much more than a flowmeter, the AF2 has made a significant contribution to help facilities across a wide range of industries better control their air consumption and meet sustainability goals. The AF2 is a critical part of the compressed air monitoring solution we provided when we recently helped a consumer products leader pursue its 2040 net-zero carbon target.

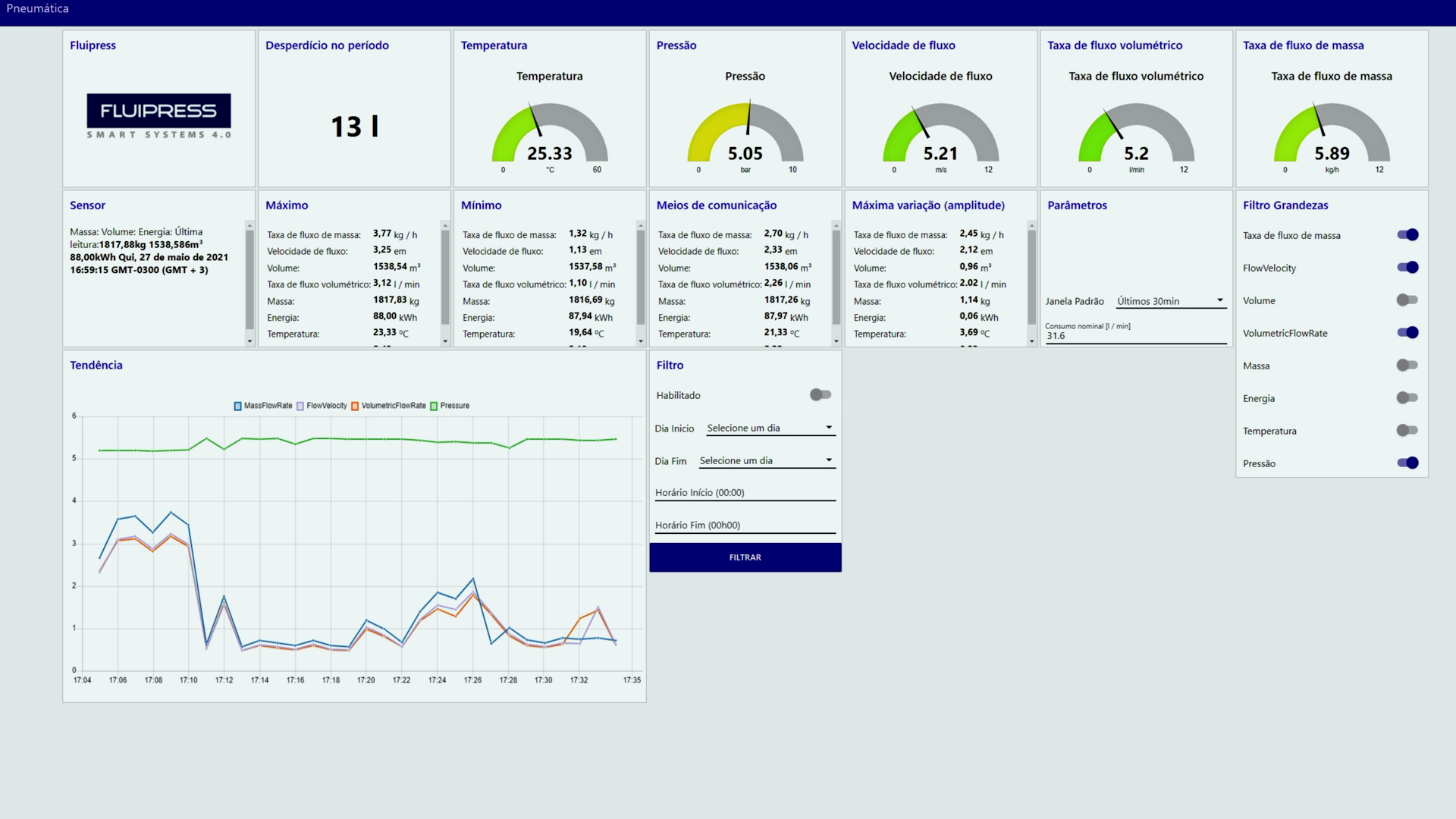

Large-scale consumer goods production relies heavily on pneumatics, so helping our customer reduce the amount of energy used to produce compressed air contributed directly to their sustainability efforts. In addition to AF2 sensors, the project used IIoT-enabled software architecture to precisely monitor compressed air flow in real time to identify leaks, optimize pneumatic processes, and improve air flow efficiency.

The implementation calculates air usage data with integrated software that displays trends and anomalies on analytics dashboards, allowing operators to easily regulate supply pressures and detect leaks. The system’s built-in connectivity makes it easy to deploy and provides immediate insights at the machine level, with network capability paving the way for monitoring compressed air usage throughout the enterprise.

Using Emerson’s advanced sensor technologies and analytics, the company has already seen a 15% reduction in energy usage on several packaging lines and expects even greater energy savings as the technology rolls out more widely.

Another way Emerson has helped manufacturers meet their sustainability targets is with Branson’s ultrasonic welding technologies. By working with OEMs to determine innovative ways of cutting, sealing, and joining new biodegradable packaging materials, Branson’s technologies reduce waste otherwise bound for combustion or landfill.

While reducing energy consumption can reduce emissions, there are other ways we’re helping our customers manage and reduce emissions too. For instance, nearly half of all emissions in major oil basins are from storage tanks, and open thief hatches are the primary way these emissions escape. To limit emissions, governments have taken regulatory action, with some requiring daily documentation of thief hatch status.

Using our TopWorx proximity-sensing technology, we’re helping our customers in the oil and gas industry remotely monitor thief hatches on their storage tanks around the clock to ensure they’re securely latched. The TopWorx GO Switch Model 73 precisely and continuously monitors hatch position in real time, allowing operators to properly account for thief hatch status that regulations require.

Through this framework, we’ve amplified our efforts to decrease our environmental impact by working together, by improving our own sustainability, by supporting our customers’ sustainability efforts, and by partnering with local and global organizations in service to our planet. What we’re doing is a priority that’s vitally important – important to my daughters, their generation, and the many generations to come. We see it as more than our duty; it’s our purpose to drive innovation that makes the world healthier, safer, smarter – and more sustainable.

For more information, visit www.emerson.com/en-us/esg.