Endress+Hauser Launches Clamp-on Flow Meters

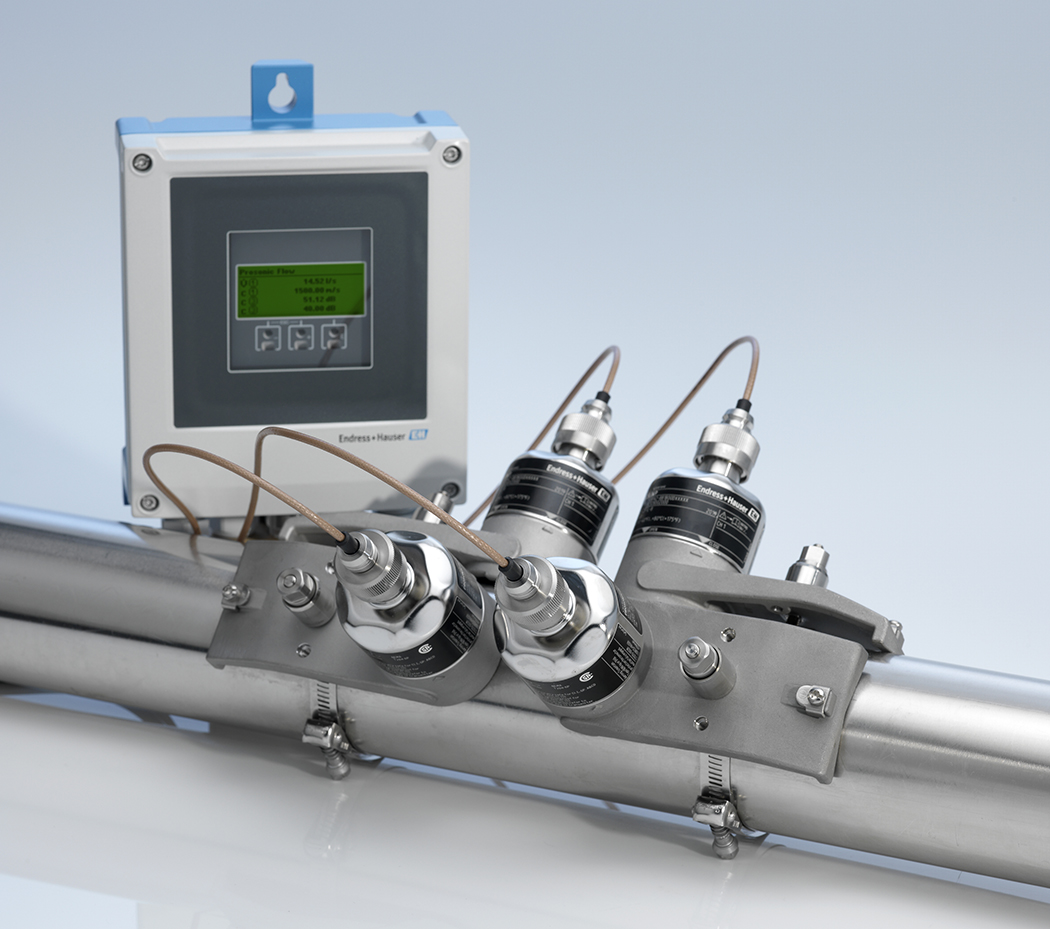

Endress+Hauser recently added the Flow W 400 to its Proline device series of clamp-on ultrasonic flow meters. The W 400 clamp-on and I 400 insertion units provide comprehensive process monitoring with long-term cost efficiency and extensive diagnostics. These sensors pair with Endress+Hauser’s Proline 400 transmitter to provide a complete flow metering solution.

The flow meter uses a nonintrusive, clamp-on measurement method, with its ultrasonic sensors mounted directly on a pipe’s exterior. This provides safe measurement of many fluids, independent of their conductivity or other properties. This includes corrosive, abrasive, and toxic fluids, making this flow meter ideal for monitoring countless processes.

Because neither piping nor process flow are interrupted, clamp-on flow meters can be easily retrofitted anytime. They are suitable for low- or high-pressure applications, on pipes smaller than an inch in diameter and up to 160 inches, such as those encountered in water distribution.

This size range illustrates the Prosonic Flow W 400 measurement solution’s versatility. It can be used to measure flow, monitor processes, verify previously installed flow meters, detect leaks in a pipeline, and for other applications.

The flow meter’s IP68 Type 6P submergence-rated ultrasonic sensors provide long-term and reliable operation, requiring little maintenance. This makes them suitable for use in harsh process and ambient conditions, able to withstand temperatures from -40°F to 266°F (-40°C to 130°C).

The Proline 400 transmitter includes a built-in web server, so users can access process, diagnostic, configuration, and other instrument data via any device capable of hosting a web browser, such as a laptop, smartphone, or tablet.

The transmitter provides targeted parameterization of measuring points, and it saves time during commissioning, maintenance, and service. Its LCD display and web-based operating tool each show real-time measurement quality—good, acceptable, or bad—to provide key status information at a glance.

Prosonic Flow W 400 can be mounted on a wide variety of pipe types and materials with or without lining, including metal, plastic, glass-fiber-reinforced plastic, and composite materials. A maintenance-free contact medium, called a coupling pad, provides optimum sound transmission between sensor surface and the pipe, and the resulting high signal strength ensures stable measurement results and long-term reliability. These clamp-on flow sensors are available in multiple ultrasonic frequencies ranging from 0.3 to 5 MHz, optimized for application pipe size, pipe material, and fluid.

For more information, visit https://eh.digital/3Kljyuf and https://eh.digital/3furcnJ.