Festo Controls Help Glue Electronic Components

Precisely gluing smartphone displays, applying thermal paste, or gluing micro cameras in place are examples of adhesive processes that represent the dosing and dispensing competencies of ViscoTec, of Töging am Inn, Germany, near Munich. The company has introduced cartridge applicators that feature Festo pneumatic control modules for exact and clean feeding of adhesives, pastes, and silicones of different viscosities.

Precisely gluing smartphone displays, applying thermal paste, or gluing micro cameras in place are examples of adhesive processes that represent the dosing and dispensing competencies of ViscoTec, of Töging am Inn, Germany, near Munich. The company has introduced cartridge applicators that feature Festo pneumatic control modules for exact and clean feeding of adhesives, pastes, and silicones of different viscosities.

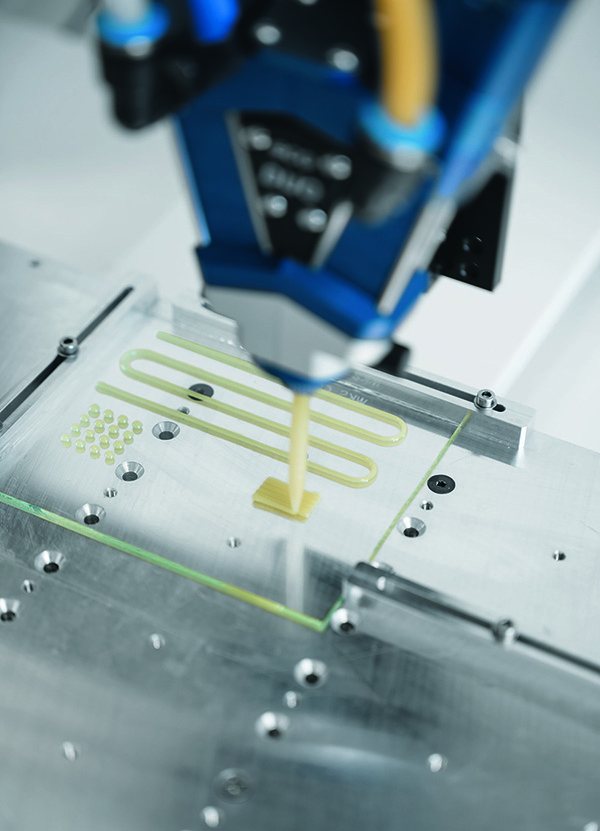

Applying thermal paste.

The eco-FEED and vipro-FEED DC are the latest devices for automated, even application of double-chamber cartridges. Double-chamber cartridges make it possible to work with media like adhesives, pastes, or silicones with two components of different viscosities. Many adhesive processes depend on these adhesive components being mixed in a precise ratio. In this process, the two applicator cylinders move independently of each other and apply the correct adhesive mixture to the components to be glued.

Festo’s eco-FEED.

Especially in the electronics industry, minute quantities need to be applied precisely and reproducibly to circuit boards, for example, or gaps need to be precisely filled on different electronic components, often using highly abrasive pastes. These application conditions make correct control and indication of the delivery pressure crucial.

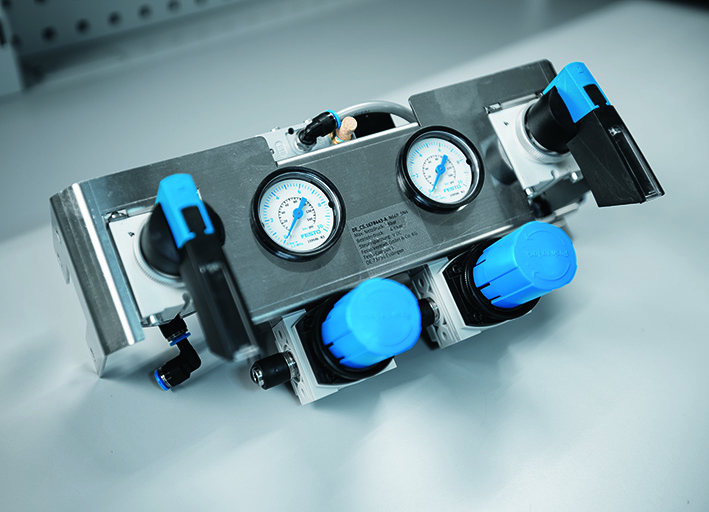

The control module is a ready-to-install device delivered by Festo directly to the ViscoTec assembly line. The control module monitors the pressure and quality of the adhesive application independently of temperature and viscosity. It enables volumetric filling. The module offers optical filling level monitoring as a standard feature. Customers have the option of an electric level monitoring version.

Festo’s control module monitors adhesive application.

The double cylinder control module consists of a Festo VUWS valve, VHER hand lever valves, flanged pressure gauges, LR-D pressure regulators, fittings, silencers, and PUN tubing.

The appeal of this new development is that the precision application of the adhesive leaves no rims of adhesive on displays or micro cameras and no adhesive oozing from the corners and edges on glued components in everyday consumer goods.

For more information, visit www.viscotec-america.com or www.festo.us.