Festo Talks Valves, Energy at Hannover

Festo launched a line of new valves as well as energy-saving services and products at this week’s Hannover Messe trade show in Germany.

Media-separated solenoid valves

Festo launched three media-separated solenoid valves at Hannover.

The VYKA, VYKB and VZDB valves allow for dosing, aspirating, and continuous flow operating modes. The compact yet powerful valves dose and aspirate even small quantities with a high level of precision. Thanks to their impressive pressure and nominal width specifications, they are also suitable for controlling the flow in a manifold duct plate, for example.

The valves can easily handle vacuum as well as pressures of up to 3 bar and Kv values up to 969 ml/min. Their small grid dimensions make them suitable for a wide range of applications, such as the VYKA with microwell plates. The high-performance polymers EPDM, FKM, and FFKM used for the separating diaphragms can withstand even aggressive media, protect the interior of the valves, and simultaneously prevent corrosion. This is ideal for sensitive applications because the low internal volume makes the valves easy to clean. The media-separated valves cover a range of nominal widths. You can choose between nozzle widths of 1.2 mm, 1.6 mm and 2.0 mm.

The valves come with different actuation options (3/2, 2/2 NC, 2/2 NO). All three valves are extremely precise when it comes to controlling liquid amounts in the microliter or milliliter range in various dosing and flow applications.

With the VYKA, the 12 … 26 V DC actuation of the plug-in electronic connecting component (E-box) VAVE or the valve control module VAEM reduces the holding current. This valve is 7 mm wide. The holding current reduction prevents sensitive media from heating up. With the VYKB, unlike the VYKA, the electronic connecting component is integrated and can be actuated using 12 V or 24 V. It is 10 or 12 mm wide. In contrast to the VYKA and VYKB, the media-separated valve VZDB is actuated using compressed air. It is 10 mm wide.

The excellent performance of the liquid valves makes them a suitable choice not only for laboratory applications and in-vitro diagnostics but also in the perfume and flavor industries as well as for emissions units.

Other applications include media handling in the semiconductor industry, e.g., manufacturing wafers, 3D printing, or printing packaging. The three solenoid valves are also a solid choice for cleaning processes for cuvettes and needles or for agricultural equipment like milk pumps.

For more information, visit www.festo.com/us/en/.

Energy-saving services and products

To address the efficiency concerns of companies, Festo launched its Festo Energy Saving Services (FESS) to help automation technology users produce more energy efficiently in their factories.

Festo auditors put the entire compressed air system through its paces. Modern compressed air systems are very efficient, but old ones that have grown over many years are not. Festo helps customers to assess their own system, identify potential savings, and propose and implement solutions or improvement measures.

A new addition to the portfolio is a monitoring system that Festo implements permanently at the customer’s premises. The entire compressed air system is constantly monitored via built-in sensors, such as flow and pressure sensors. The measured values are recorded, processed, and visualized for the user in an AI-based software solution developed by Festo. This provides the customer with permanent condition monitoring of their system. The system reports deviations and faults in good time so that they can be rectified by adjustments or repairs.

With Festo Energy Saving Services, customers analyze and optimize their entire compressed air system in accordance with the ISO 11011 standard, to which Festo was the first company in the world to be certified for compressed air audits by TÜV Süd.

For an energy-optimized system design, Festo offers both a complete pneumatic and an electric portfolio with comparative calculations for both drive types.

The C2M module.

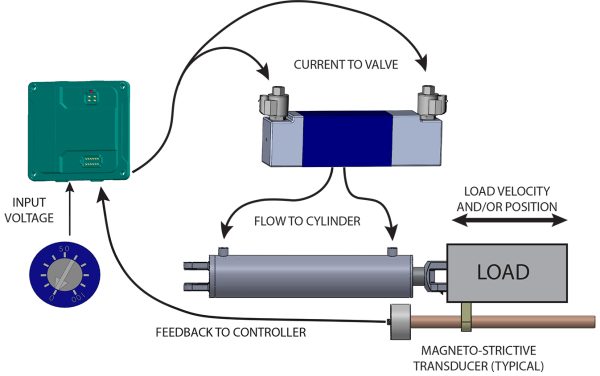

Digitalization is an important enabler for transforming industrial production in a climate-neutral way. For example, the digital valve terminal VTEM controls the energy supply according to demand. In addition, integrated pressure sensors can provide information on leakage conditions. These are interpreted decentrally on the controller and recommend planned maintenance cycles for the system. VTEM works with energy-saving piezo valves. These consume 20 times less energy with a 20 times longer service life. They are quiet yet highly precise for controlling the smallest flow rates.

Another smart product is the C2M energy efficiency module, which combines pressure regulator, on-off valve, sensor technology, and fieldbus communication in one unit. It monitors compressed air consumption, shuts off the compressed air during nonproduction periods after a defined waiting time, and prevents the system pressure from falling below a defined standby pressure level.

The VSVA pulse valve.

The pulse valve VSVA is one of the newly developed, particularly energy-efficient products used for cleaning chips or dust, drying, and transporting parts. Due to the pulsating blowing, the blowing impulse is stronger than with continuous air flow. Suspending the blowing process saves up to 80% energy.

The OVEM vacuum generator.

In the field of modern vacuum generators, Festo has the OVEM vacuum generator in its portfolio. It has an integrated air-saving circuit and can monitor the vacuum pressure. Once this is reached, it switches off vacuum generation – up to the point where the correct vacuum has to be built up again. This is because a constant vacuum pressure is not necessarily required to hold objects securely with vacuum. For smooth surfaces, the air-saving circuit is particularly efficient and reduces air consumption by up to 60%.

For further information, visit www.festo.com/energysaving and www.festo.com/energyefficiency.