A New Generation of High-Performance Heavy-Duty Piston Pumps

From Hengli America

Hengli Hydraulic’s V30G series heavy-duty axial piston variable displacement pump was specially designed for continuous heavy-duty applications. The product was developed by Germany’s InLine Hydralic Co. based on its 70-year history in research and manufacturing of heavy-duty piston pumps combined with the application experiences and technologies of Hengli’s V30D and V30E series pumps.

To meet the working requirements of different applications, the V30G series offers a variety of displacement and control options, such as the control modes for power, pressure, load sensitivity, electric proportional displacement, and so forth. The flange design can be tailored to customer requirements for more flexible mounting. In high speed and high torque working conditions, the pumps can be used on the mobile machinery such as concrete pumping units, cranes, drilling rigs, and the hydraulic systems of shield machines, forging presses, and extrusion presses.

Compared with the previous series and similar products on the market, the V30G series has made the numerous improvements in general performance:

- Digitized closed loop control, improving precision. By combining the control unit with the sensors, the digitized closed loop control of the hydraulic pump opens up new possibilities for precise flow regulation, energy saving, and efficiency improvement and remote fault diagnosis. Closed loop control integrated with angular sensors effectively reduces hysteresis and improves control precision. Integrating the vibration, pressure, temperature, and other sensors with intelligent control and working condition data analysis and processing achieves whole-life-cycle monitoring.

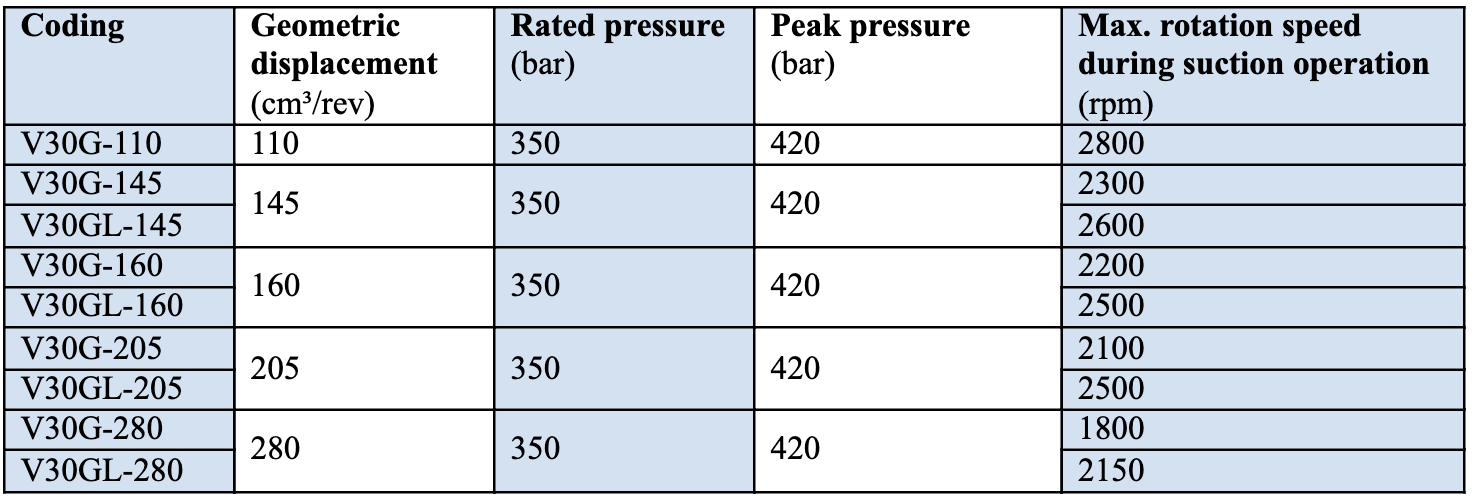

- Greater pressure and rotating speed range. The nominal pressure of the V30G series is 350 bar (5,076 psi), and the peak pressure is as high as 420 bar (6,091 psi). The higher pressure results in a lower flow rate for transmitting the same power and reduced flow loss in the hydraulic system, which effectively achieves energy saving and emission reduction. The pump is equipped with spherical flow distribution and an optional built-in booster impeller, which increases the nominal rotating speed of the pump by about 10%, suitable for use in high-rotating-speed working conditions.

- Optimized design. With variable structure design, double pistons drive the swash plate variables. Compared with the single-piston variable mechanism, it has the advantages of balanced stress and faster response. Use on machinery with fully electrical and intelligent closed loop control systems achieves higher precision control. The pressure block structure fixes the reinforced slipper guide retainer for higher rigidity. The slipper, with a steel matrix, greatly improves pulling-out force, improving the pump’s antifouling ability and reducing the possibility of failure, such as slipper guide retainer breakage and widened piston clearance caused by contamination. Through analysis on the shell stress, stiffeners are structurally arranged to effectively reduce the wall thickness of the pump while maintaining the rigidity of the structure. This design not only reduces the weight of the pump but also ensures the stability of the pump body, reducing vibration and noise.

- Improved heavy-duty pump. Improved heavy-duty bearings ensures longer service life. Together with the improved slewing assembly, the pump can work reliably for longer under high-pressure and heavy-load conditions.

The V30G series has been used in concrete pumping units, cranes, and extrusion presses in China and shows stable operation and excellent performance. In the future, mobile machinery and other equipment may operate more accurately and efficiently.