Filler Breathers Improve Long-Term Hydraulic System Performance

By Todd Klitzke, Engineering Manager, Zinga Industries, Filtration Group

Illustrations by Craig Churchill, Engineering Tech, Zinga Industries, Filtration Group

Maintaining the cleanliness of a hydraulic system is of the utmost importance for minimizing problems such as component wear and subsequent failure. To avoid these and other system problems significant focus is placed on removing particulate from hydraulic fluid via various hydraulic filters, both on the high-pressure side, as well as on the return to the reservoir. Much attention is given to these critical filter choices, but placing focus on the prevention of contaminant ingression into the hydraulic system is also important. Filler breathers provide multiple means of reducing contaminant ingression, which is a key to maintaining the ISO cleanliness codes required for the long-term health of a hydraulic system.

Filler breathers are present on nearly every hydraulically operated system. As their name states, filler breathers serve the critical dual functions of providing a fill location for filling and topping off the fluid and acting as a tank breather device, allowing air to flow in and out of the reservoir. However, a wide array of options exists to tailor filler breathers to meet the unique requirements of a given hydraulic system. Often system designers may select a filler breather based upon cost or what is “on the shelf,” unaware of the customization options available and the subsequent benefits to the hydraulic system or the problems that can occur in the hydraulic system from improper selection of a filler breather.

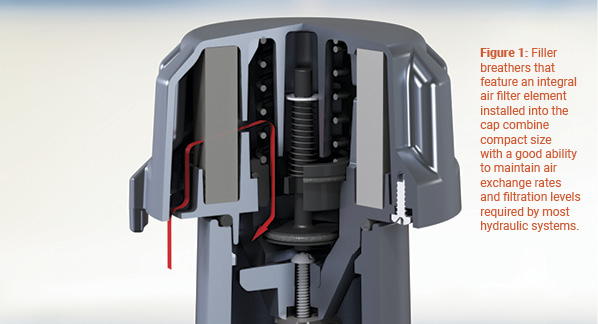

The most important method of preventing contaminant from entering the system is by filtering the air passing through the filler breather into the reservoir. Many filler breathers feature an integral air filter element installed into the cap (Figure 1).

Filter Media Types

Open cell foam is the most common choice of air filter media. Filtration levels of open cell foam range from 40 micron in lower cost versions down to 10 micron nominal for many applications. This foam filter material is often chosen for its long operational life and air filtration properties while still maintaining low airflow restriction. It is worth noting that other media types are also available, including phenolic cellulose, for improved particulate removal that can provide air free of particulate down to 1 micron at up to 99% removal efficiency.

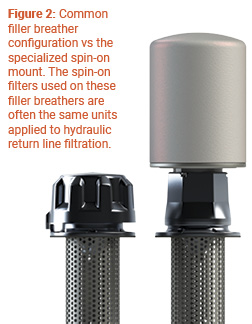

Another type of even more specialized filler breather foregoes the internal filter material and instead incorporates a mounting location for either direct or remote mounting of a spin-on filter.

Spin-on filter filler breathers allow for greater media area, increased contaminant capacity, and the ability to replace the filter media without replacement of the cap assembly. These specialized filler breathers are well suited for heavily contaminated environments with high levels of particulate in the surrounding air. The trade-offs being increased cost and greater space requirements. It is important to consider the operational environment, space constraints, system cleanliness level requirements, and other filtration within the system when selecting a filler breather.

Filler Breathers as a Fluid Fill Location

Serving as a fluid fill location is another important function of filler breathers. When adding fluid to a hydraulic reservoir, many opportunities exist to introduce contaminant into the system. The fluid being added to the reservoir may contain contaminant that was introduced during transport or storage. In addition, some hydraulic systems operate in dirty environments where any number of contaminants can collect on the reservoir surface and around the filler breather.

Serving as a fluid fill location is another important function of filler breathers. When adding fluid to a hydraulic reservoir, many opportunities exist to introduce contaminant into the system. The fluid being added to the reservoir may contain contaminant that was introduced during transport or storage. In addition, some hydraulic systems operate in dirty environments where any number of contaminants can collect on the reservoir surface and around the filler breather.

Most mobile applications suffer from variable operating conditions and are particularly susceptible to intrusion during filling. If care is not taken, these contaminants can fall into the reservoir when the cap is removed, or if an operator neglects to replace the cap. Many filler breathers have baskets that provide a basic level of protection by both filtering the oil being added and catching contaminant that may fall into the filler opening when the cap is removed.

When selecting a basket for a given application it is important to consider the strainer material, filtration level, fluid viscosity and anticipated fill rate. Low cost versions of these baskets are made of plastic while more robust versions use expanded metal or perforated steel baskets with various length options generally ranging from 4 to 12 inches long. These materials provide a very coarse filtration level removing only large, macroscopic contaminant. Stainless steel wire mesh liners may be added into the perforated steel baskets to improve filtration levels down to 75 micron. Baskets that provide better filtration levels also are more restrictive to flow, often requiring a longer basket to accommodate the same fluid fill rates as a shorter basket with a lower degree of filtration.

Valves Control Air Flow and Contaminant Ingression

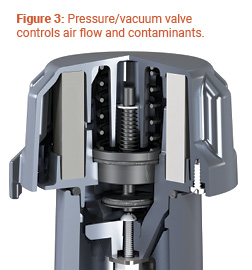

The third method to reduce contaminant ingression does not involve filtration, but rather valves. Filler breathers without airflow valves allow uncontrolled venting 24 hours a day, even if the system is not in operation. This allows for an even greater opportunity for both particulate and moisture ingression into the system. A pressure/vacuum valve (Figure 3) located in some filler breather caps serves multiple functions including controlling the airflow and the contaminants it carries into the reservoir.

The third method to reduce contaminant ingression does not involve filtration, but rather valves. Filler breathers without airflow valves allow uncontrolled venting 24 hours a day, even if the system is not in operation. This allows for an even greater opportunity for both particulate and moisture ingression into the system. A pressure/vacuum valve (Figure 3) located in some filler breather caps serves multiple functions including controlling the airflow and the contaminants it carries into the reservoir.

A pressure/vacuum valve only allows air to pass into the reservoir as the reservoir oil level is dropping, for example, when cylinders are extended. When the oil level is constant, the valve remains closed, thereby blocking virtually all contaminant during that time. As oil levels in the reservoir rise during transient operations, the pressure/vacuum valve holds pressure in the reservoir, which also helps to limit unnecessary venting and contaminant ingression. This valve also serves the important role of maintaining positive pressure at the pump inlet and reducing the likelihood of pump cavitation.

The three modes of preventing contaminant ingression (oil filtration, air filtration, and air flow control) are important and often overlooked benefits of selecting a high-feature and high-quality filler breather. Selecting a filler breather that includes these features matched specifically to the system, as well as its operating environment ensures long-term improved system performance with less downtime.