Filtering Compressed Air to Protect Equipment & Processes

By Charles Werdehoff, IMI Norgren

When using compressed air to open valves, move cylinders, or power pneumatic tools, good air preparation is critical to the process. The first step is filtration. Particulates, water, and oil in compressed air can wreak havoc with downstream equipment. Particulate contamination can cause valves to fail prematurely. Moisture and oil can degrade seal materials. Oil contamination will cause regenerative dryer media to fail immediately and completely. Dirty air reduces efficiency and shortens equipment service life.

There are three widely used types of filters for conditioning compressed air: general purpose, coalescing, and activated carbon.

General-Purpose filters

General-Purpose filters

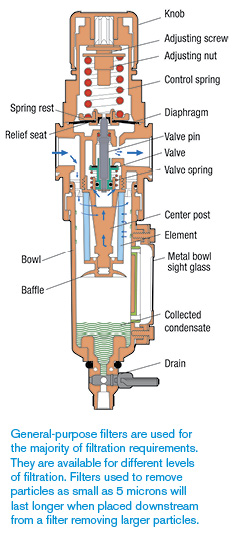

The majority of filtration needs can be met with a general-purpose filter. Some common uses are main headers, branch lines, tools, cylinders, valves, and valve circuits and air agitators. General-purpose filters work by admitting dirty, moist air through the inlet port and into louvers. These centrifugally separate entrained liquids and particulates, which then fall to the bottom of the bowl. Near the bottom of the bowl, a baffle creates a quiet zone, preventing the turbulent air from recapturing the contaminants. With the largest water droplets and particles removed, the air then moves through the filter media to remove smaller particles.

General-purpose filters are available in different levels of filtration, most often removing particles ranging in size from 40 microns down to 5 microns. A 40-micron filter is suitable for most industrial applications. The smaller the micron rating, the higher the pressure drop, so it is not efficient to use a finer filter than the applications requires. The service intervals for cleaning the filter element are also shorter with a finer filter because small holes plug quicker than larger ones. A small-micron filter should only be used when a tool requires very small particles to be removed. The element will last longer when placed downstream from a larger micron filter.

In addition, a general-purpose filter should be used upstream of filters used to remove oil or oil vapor. Removing water and particulates down to 5 microns will prevent the coalescing or carbon filter from being choked or blocked, extending element life.

Coalescing Filters

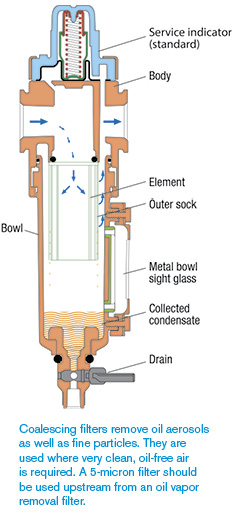

Air compressors often introduce oil aerosols in the air. Oil-removal filters work by coalescing this oil mist as it passes through fine fibrous filtration media. Oil droplets are collected in an outer sock surrounding the element and then dropped to the bottom of the bowl for easy removal. The bottom of the sock will become visibly saturated with oil; this is the normal operating condition for oil removal.

Most coalescing filters will also reduce particle contamination to less than 1 micron.

Coalescing filters are used where very clean, oil-free air is required, such as supply to fluidic devices, instrumentation, air gauging equipment, and air bearings.

Activated Carbon Filters

Activated Carbon Filters

Carbon filters are used to remove oil vapors (odors). This is important for applications that require very clean air, such as instrumentation or paint-spraying systems. Activated carbon is porous, resulting in a large surface area. Oil vapors are attracted and adhere to this surface. The element usually includes a filtration medium in the activated carbon element to prevent carbon particles from migrating downstream.

Drains

The condensed moisture that is removed from the air collects at the bottom of the filter and must be drained. Filters can be supplied with semi-automatic, automatic, or manual drains. A semi-auto drain opens when the airline is depressurized—for example, at the end of a shift. It can also be operated manually as required.

An automatic drain is a two-way valve that closes when the system is pressurized and opens to drain when a float rises to a certain level. It will also open when the airline is depressurized. Automatic drains should be used where the filter location may make servicing difficult, where filters are hidden and may be overlooked, or where equipment is in continuous use. They are also useful for applications where large quantities of liquid might accumulate quickly.

Manual drains are used in drier environments where only occasional bowl drainage is needed. They are also suitable where regular preventive maintenance is sufficient to ensure condensate is removed from the filter

Drip Leg Drain

When systems are shut down, they cool, and water condenses in the low points of the piping system. Then, when the process starts up, the water can be pushed to the nearest device and cause malfunction or damage. The problem can be prevented by running a vertical pipe from these low points so water runs into a drip leg drain where it can be expelled by an automatic drain.

Conclusion

Proper filtration of compressed air will keep equipment and processes running longer and more efficiently. Users should follow equipment suppliers’ recommendations for the level of filtration. They will specify the level of air quality required to keep their equipment operating most efficiently and for the longest life. Standards are commonly based on ISO 8573-1:2010. Conditions where the filter will be operating should also be considered in order to get the right design and material.

For more information: Charles Werdehoff is product marketing manager (FRLs) at Norgren, Inc.—an IMI Precision Engineering Branded Company. Visit www.imi-precision.com.

the website is very supportive, thank you