Fluid Power is Dead

By Rance Herren, Founder, Fluid Power SME.

By Rance Herren, Founder, Fluid Power SME.

If a headline like this in a fluid power magazine does not grab your attention, I’m not sure what will. But if you are with me this far, stick around because it only gets more irreverent.

“Heresy,” you say and if you attended the International Fluid Power Exposition (IFPE) show this past March in Las Vegas and observed what I did, I would no doubt agree. In partnership with the CONEXPO-CON-AGG show, IFPE featured over 375 exhibitors from around the globe, all converging in one location, many after a six-year absence. In addition to the massive number of component and equipment manufacturers, the education track provided over 170 unique sessions with 27 geared specifically to the fluid power minded. IFPE and CONEXPO-CON-AGG attendance was spectacular and has been reported as the largest in show history, even eclipsing the annual Consumer Electronics Show.

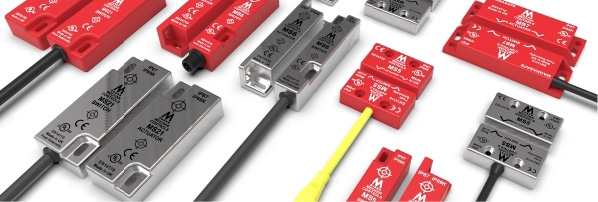

Among the many conversations happening – including those about the most comfortable shoes to wear on the show floor (with seemingly equal intensity, curiosity, and enthusiasm), were those about the various suppliers and what is new. Along with the regulars we expected to see, there were many newcomers from eastern and southern Asia and strong showings from Italian and other European manufacturers. There were many clever innovations such as LEAP award winner DGD Fluid Power and their Cartridge Flow Sensor; new spins on old technology like gear pumps with significantly reduced noise levels and directional valves optimized for energy efficiency and more component manufacturer options for machine builders (and those who would supply them) than ever before. Danfoss is no doubt bullish about the future of fluid power as they proudly promoted their acquisition of Eaton’s Hydraulics Division and launched their very novel Digital Displacement Pump. Hardly the actions of a company that believes fluid power is a dinosaur destined for extinction.

Another interesting observation was how many large as well as small manufacturers are seemingly trying to “out-green” each other. But when pressed on how exactly they plan to make it happen, the answer often pivots to the goal rather than the current state or future reality. That is not to say there are not great ideas such as variable speed pump drives, energy recovery, and other efficient hybrid technologies (there are), but many, especially in the areas of electrification do not address the need for massive physical infrastructure to support it. And as industries battle it out over the moving targets of energy efficiency, electrification, and ecology, the one constant that not only remains but is increasingly becoming the elephant in the room is just who on the factory floor is going to manufacture and repair all of this clever technology?

The younger talent needed in the skilled trades is not keeping pace with the demand as older employees leave the workplace and as increasingly difficult as it will be to find this new talent, it will even be more difficult to transfer the knowledge base unless they have the necessary skills to understand and apply it. According to The Manufacturing Institute citing a Deloitte study, as of January 2023, there were over 803,000 manufacturing job openings. And of the over 4 million U.S. manufacturing jobs that will likely be needed in this decade, over half are expected to go unfilled. Moreover, if we do not inspire more people to pursue modern manufacturing careers, these missing jobs could potentially impact the economy by $1 trillion in 2030 alone.

There is a lot at stake but at the same time, great opportunity for those willing to learn new skills and work hard in applying them. Data from the U.S. Bureau of Economic Analysis and Bureau of Labor Statistics, in 2021 shows that manufacturing workers in the United States on average earned $95,990 in salary and benefits. These are good jobs with good pay for those who have the skills. But to get there, industry, in partnership with government, academia, and the private sector must be at the forefront of the effort to prepare the workforce. And this effort must include fluid power as a viable and necessary technology.

So, as I reflect back on the success of another IFPE show, I am reminded of the saying that the more things change, the more they stay the same, and sometimes that is truer than we like to admit but this is serious stuff – the development of the next generation of talent is as deserving of the industry’s love and attention as any new technology. But despite the seeming impertinence of this article and with all apologies to Mark Twain, I can say with absolute certainty the reports of fluid power’s death by its technological rivals have been greatly exaggerated. The reality is that fluid power is very much alive and kicking. And wearing sensible shoes.