Notable Words: Inspiring the Next Generation of Engineers

By Eric Alström, President, Danfoss Power Solutions.

By Eric Alström, President, Danfoss Power Solutions.

As university students near graduation, their thoughts turn from coursework to career. With various occupations and industries to consider, engineering graduates are often excited about solving complex electrical or mechanical challenges and having a positive impact on the planet. Many look to the automotive, aerospace, and other industries that have a technology-forward image and align with their ambitions to contribute to a better world. Often, the company names are well-known consumer product manufacturers.

Rarely, however, do graduates discover the hydraulics industry and the many opportunities it offers. Fluid power companies need to work hard to attract engineers, usually because of the old-fashioned image that oil hydraulic products represent. However, that image couldn’t be further from reality. We need to both familiarize and excite aspiring engineers with the cool things that characterize our products today.

We also need to raise awareness of the substantial technical developments required to serve the next generation of sustainable development in our industry. As president of one of the world’s leading hydraulics suppliers, I call this “opening the Danfoss box.” Virtually no hydraulic applications can run today without software, microcontrollers, sensors, and electrically actuated hydraulic pumps, motors, and valves. This presents a fascinating multidisciplinary mechatronics problem that should excite the most technically interested engineers. In fact, electronics and software are so important that about half of our 1,800 engineers are developing software and connected products.

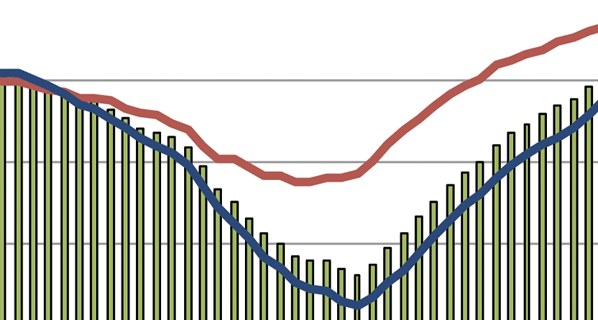

The potential to lower emissions and improve productivity through better technology is significant. Hydraulic systems generate many of the energy losses that occur in a diesel-powered machine. The more efficient we make the hydraulic system, the greater the overall machine efficiency. But for many customers, that isn’t enough. Productivity is just as or perhaps more important than efficiency. This is where control systems, software, and intelligent products come into play. They are tools to solve the challenging design problems of machines. Once engineers understand the contribution of these technologies to optimizing fuel efficiency, productivity, and even the circularity of products – particularly as the ESG (environmental, social, and governance) movement rapidly grows in importance – they tend to raise hydraulics on their list of potential industries in which to work.

Electrification also increases the attractiveness of our industry to young engineers. Many of our solutions today are electrohydraulic, meaning electronic controls and/or electric motive power driving hydraulic systems. Their positive impact on productivity and efficiency is significant. Some cases have shown over 30% improvement in productivity while operating emission free and using less energy. The benefit to society is tangible and exciting. When engineers learn they can develop green solutions that enable us to produce more with less, they quickly become interested in working for us.

Solutions is another keyword that attracts engineers to our business. Many OEMs are outsourcing hydraulic and system design to suppliers like Danfoss. Our impact on overall machine performance grows as we are given more of the system to control. In fact, from a hydraulics standpoint, we sometimes understand the applications better than our customers, as we interact directly with end users to better understand their needs. Gaining this in-depth application know-how and experience in systems engineering appeals to young engineers. For many people in the field, engineering an entire system is a dream; in hydraulics, it is often reality.

However, all of these fascinating facets of hydraulics only become interesting to a young engineer when we “open the box.” It is no small challenge, and we need to be close to the emerging technical talent at universities to make it happen. As an industry, we need to commit to supporting education by investing time and money. We can offer internships and provide equipment for labs and classrooms. Equally important, we can be present in classrooms and cocurricular activities, serving as role models for tomorrow’s engineers. After all, collaboration moves us all forward together.

Hi sir,

This is Anand Pandey

I’m interested in a full-time position, and I was hoping to get some guidance from you and how I could get enrolled into your organisation.

Thank you,

Anand Pandey