Gas-Charged Hydraulic Accumulators

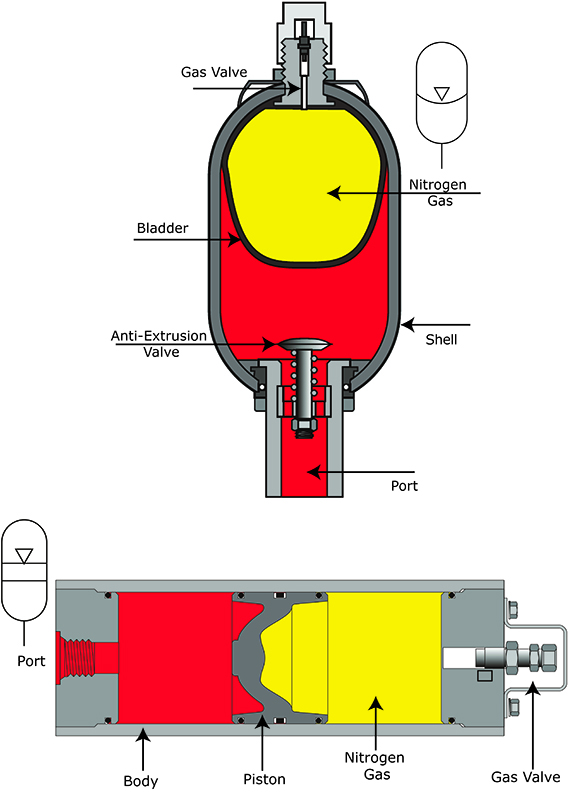

Bladder andpiston-type accumulators.

Accumulators are pressure vessels and are subject to the American Society of Testing Materials standards in addition to the International Standards Organization and the Occupational Safety and Health Administration guidelines. The use of accumulators may be subject to additional regulations, depending on location and application. Local and industry-specific standards should be investigated to confirm compliance. The accumulator manufacturer’s literature should be reviewed for additional recommendations and limitations. Because accumulators are pressure vessels, they cannot be modified in any way except by the manufacturer. Information concerning mounting and securing accumulators is also provided in the standards and guidelines. Note: Accumulators should be mounted vertically.

The precharge pressure of an accumulator is the pressure reading in the bladder when the accumulator is empty of fluid. The precharge requirement of the accumulator will vary based on the application, independent of the accumulator size. Common applications are to supplement pump flow, provide short-term back up power, absorb hydraulic shocks, or maintain system pressure. If the precharge pressure is low, the system operation will be sluggish. Low precharge in accumulators used for surge protection will allow a system with high system shocks to knock and make noise. If the precharge pressure in a bladder-type accumulator is high because the accumulator was precharged to a higher pressure than manufacturer specifications, the bladder may fail. Under normal operation, the bladder is compressed in the shell by hydraulic oil and only expands to rest against the poppet valve in the bottom of the accumulator when the system is off. Higher-than-specified precharge pressures can cause the bladder to pound against the poppet valve in the bottom of the accumulator when system pressure drops but is still within the operating range of the machine. This will make the bladder fail where it is pushed against the anti-extrusion valve.

Accumulator precharge should be checked on a regular basis. Occasionally, the precharge of an accumulator becomes low and must be reset. This requires checking the accumulator for internal and external leaks, and then recharging the accumulator with dry nitrogen. If the accumulator shows dents or obvious damage, it must be replaced. The precharge pressure of the accumulator is temperature sensitive. To accurately test the precharge pressure, it should be done immediately after the machine has been shutdown while it is still at operating temperature.

There are a number of safety precautions that must be observed when charging accumulators. Safety goggles, gloves, and other required protective equipment should be worn, and any external leaks must be stopped before charging the accumulator. In addition, ensure that the potential hazards of working with a gas in a confined space are understood and steps taken as required to keep personnel safe. If there is fluid in the precharge gas in a bladder-type accumulator, the bladder is either passing fluid through the bladder membrane or has a leak. If the bladder is leaking, it must be replaced before recharging. If there is fluid in the precharge gas in a piston-type accumulator, the piston seal between the charge gas and system fluid is leaking.

Gas valves will vary with accumulator manufacturers and for pressures over 3,000 psi. Most manufacturers use an ISO 4570-8VI-style valve that may look like an automotive-type Schrader valve. However, it is rated for much higher pressure. The valve is used to charge the accumulator and release gas when necessary.

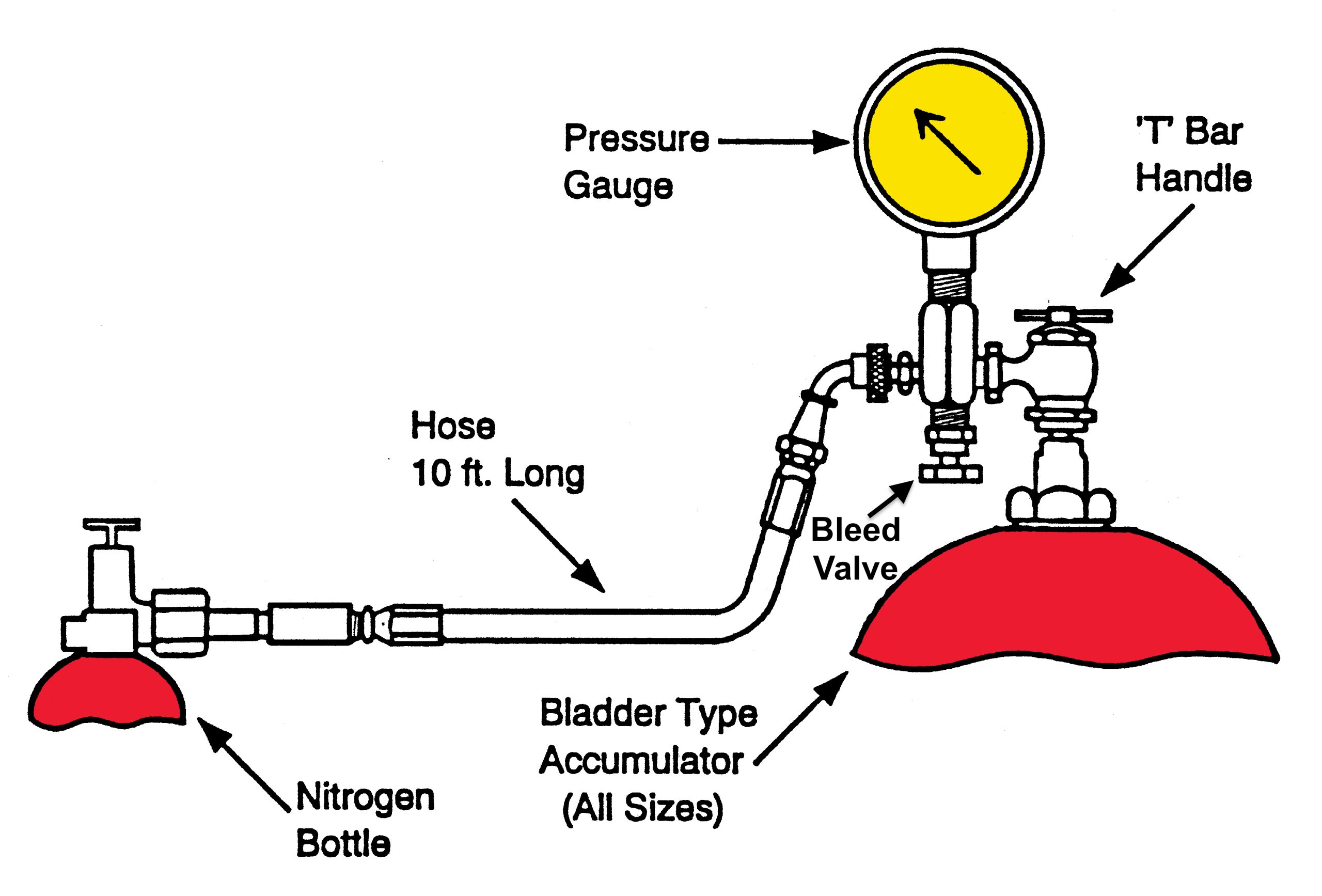

Accumulator charging valve setup.

Steps to check and add to or reduce the precharge on an accumulator are as follows:

- Ideally, the system will be at operating temperature. Lower all movable machine members, and block those that could move and injure personnel. Follow lock-out/tag-out procedures.

- The system must be shut down or the accumulator isolated, and the hydraulic pressure side drained to the reservoir.

- Before connecting the appropriate filling/testing valve and hose assembly to the nitrogen tank, ensure that all the valves are closed. Use adequate safety precautions to ensure that accidental venting of the accumulator doesn’t render the room uninhabitable due to displaced oxygen.

- Verify that the precharge pressure matches the specifications for the application.

- Remove the safety caps on both the accumulator and fill tank.

- Gently screw in the T bar handle (CW) to open the charging fill valve to allow nitrogen gas to enter the accumulator. At this time, the actual precharge pressure will be seen on the gauge when gas from the accumulator fills the line.

- Slowly open the fill valve from the top of the nitrogen tank to start charging the accumulator. Charge slowly and watch the pressure gauge for proper charge pressure. When the gas supply is turned off, the pressure will drop slightly. Add nitrogen as needed to reach the desired charge pressure. If overcharged, the fill valve can be closed and the bleed valve slowly opened to discharge excess gas. It will be extremely cold while venting.

- After filling, close the fill valve on the nitrogen tank and close the fill valve on the accumulator by turning the T handle (CCW).

- Open the bleed valve and release the trapped gas in the hose between the accumulator and the nitrogen tank before disconnecting either end of the charge/fill kit.

- Disconnect both ends of the charge/fill kit, and screw the safety caps back on the accumulator and the nitrogen tank. Be sure to secure the nitrogen tank in a proper storage place.

It is a good practice to wait a few minutes and recheck the precharge pressure. If the accumulator was charged too quickly, the expanding gas can be cooled to provide an initial inaccurate reading. Remove the hose and charge valve assembly from the accumulator, and install a tag on the accumulator noting the date and precharge pressure. Install the charge valve protection cap.

Dry nitrogen is the preferred gas used to charge an accumulator. If the application requires a different gas to be used, ensure it is inert.

TEST YOUR SKILLS

1. Oxygen must not be used to charge a hydraulic accumulator because it:

A. Is too expensive.

B. Contaminates the fluid.

C. Could cause an explosion.

D. Will leak through the bladder.

E. Has the wrong expansion characteristics.

2. What would cause hydraulic fluid to come out of the gas valve when the precharge gas is released from a bladder-type accumulator?

A. Bladder leaks.

B. Operation is normal.

C. Accumulator is overcharged.

D. Hydraulic pressure was not released.

E. Foot valve in the accumulator is stuck open.