Stay on Track: High-Efficiency Traction Control for Compact Vehicles

Especially on wet or contaminated ground, there is a risk of traction loss for mobile working machines. When attempting to increase driving safety under unfavorable surface conditions, High-Efficiency Traction Control (HET) is gaining importance. On compact vehicles, this hydrostatic drive solution provides traction on demand at any time, regardless of the ground surface, ensuring an optimal grip and maximum energy efficiency. HET is designed using standard drive components and requires no electronics to control the slip-activated all-wheel drive. A plug-and-play system for individual wheel drives makes it possible to activate all-wheel drive in certain conditions to reduce risk in hazardous driving situations. In contrast, during normal operation, HET drives a single axle to help reduce fuel consumption.

One of the most common causes of critical driving situations is the loss of traction on one or both wheels caused by surface water, ice, or contaminated ground. A technical solution to this problem is a permanent or electronically controlled all-wheel drive system. However, this entails considerable extra manufacturing costs and, in the case of permanent all-wheel drive, also leads to substantially higher levels of fuel consumption. The result is a higher Total Cost of Ownership (TCO).

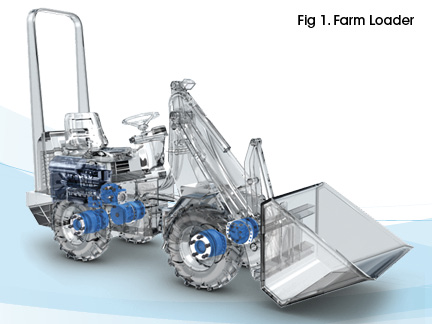

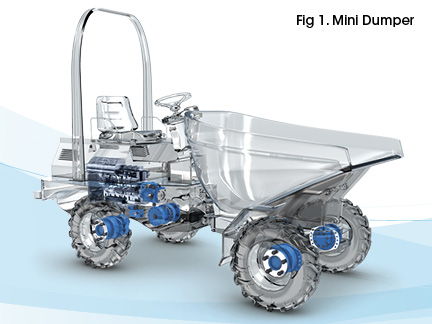

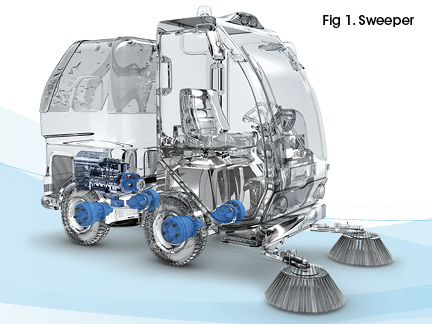

The users of compact vehicles with hydrostatic single-wheel drive systems, such as municipal vehicles, farm loaders, and dumpers (Fig. 1), are in many cases extremely sensitive to the purchasing price and operating costs. Fuel consumption contributes greatly to the running costs of such equipment.

From the manufacturer’s perspective, the HET system makes it possible to design and produce a hydrostatic four-wheel drive system with low effort. It is a purely hydraulic system with a simple, compact design that requires no control electronics and is based on proven standard components from the Rexroth mobile hydraulics range.

Back Pressure on Hydraulic Motors Destroys Energy

A common drive concept for compact vehicles is the installation of two radial piston motors in series on either side of the vehicle. When the wheel motors are connected in this way, the hydraulic oil flows through one after the other. The first motor is under load pressure or the maximum pump pressure defined by pressure cut-off. In normal driving operation, the distribution of the pressure drop across motors connected in series is more or less balanced.

As soon as a wheel transmits torque, there exists slip because the rubber of the tires is always being deformed to some extent under normal driving conditions. Even by itself, this relatively low level of slip causes a higher level of oil flow through the driving radial piston motors. When driving on hilly ground or on difficult terrain, torque increases and results in further increases in oil flow. Larger amounts of oil are trapped in the hydraulics between the driving and following radial piston motors, which leads to a significant loss of efficiency in the overall drive system. The result is higher fuel consumption when compared with normal driving situations.

On-Demand All-Wheel Drive Saves Energy

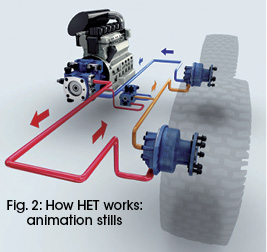

It is precisely this loss of efficiency that HET eliminates. A specially developed valve block for slip-activated all-wheel drive systems prevents the “surplus” of hydraulic oil that results from the natural slip from becoming hydraulically trapped. Instead, the valve block channels the flow of oil to the low-pressure side of the circuit to save energy. Since the HET valve block is not connected to the main oil flow, losses are reduced even further.

For the patented all-wheel drive activation system, the HET control block with integrated flow control valves creates a bypass with a constant flow from the connection between the first and second wheel motor to the low-pressure side of the pump. The amount of flow regulated by the control valve is determined by the level of slip that would occur with maximum possible torque. Since the oil flow is channeled through the bypass, the second wheel motor in the series is no longer able to build up torque. This means that the first wheel motor in the circuit transfers almost the entire torque to the axle and thus the largest possible tractive force. There is only a very small drop in pressure at the next wheel motor in the series. In normal conditions, the drive ratio between the two axles is around 90:10. This boosts efficiency in comparison to the usual 50:50 distribution. In the first approximation, HET reduces loss to one motor. Additionally, the system solution lowers the high pressure of a series circuit at the output of the first connected motor to a level similar to the supply pressure.

If the first wheel comes into contact with a smooth surface and rotates slightly faster, the flow rate through the first motor increases without proportional movement of the vehicle. The flow through the bypass block can no longer prevent the build-up of pressure and, thus, torque on the next wheel motor. At this point, the second wheel, which is still gripping the ground, takes over the drive.

If the first wheel comes into contact with a smooth surface and rotates slightly faster, the flow rate through the first motor increases without proportional movement of the vehicle. The flow through the bypass block can no longer prevent the build-up of pressure and, thus, torque on the next wheel motor. At this point, the second wheel, which is still gripping the ground, takes over the drive.

When the first wheel applies torque to the surface below again, HET resets the pressure for the second wheel back to a level close to supply pressure. The entire control mechanism is hydraulic. The operator does not need to take any action because HET automatically improves driver safety.

A Less Complex and More Compact System Design

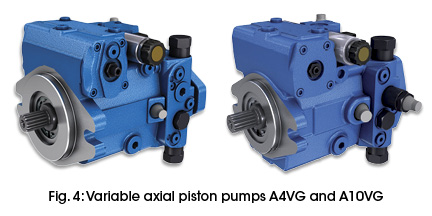

HET operates without sensors and control electronics. It consists of a newly developed valve block that is available in medium- and high-pressure versions, a broad range of A4VG and A10VG variable axial piston pumps, and MCR radial piston motors with fixed or shiftable displacement. As a result, a large number of requirements are met in terms of driving speed and installation space.

The HET Control Block: Integration of all Functions

The newly developed compact HET control block for closed circuits (Fig. 3) integrates all functions, such as a secondary supply and pressure protection.

This design simplifies the pipe work of the HET control block, which is not in the main oil flow, and reduces system costs. The integrated flushing valve creates a high level of flexibility for selection of the travel pumps, and an individually adjustable flushing flow makes it possible to manage the hydraulic oil temperature for a specific type of vehicle. The two versions of the control block cover the pressure range of 350 and 420 bar.

Transmission Pump: Proven Variety

The comprehensive range of reversible A4VG and A10VG axial piston variable pumps covers all vehicle concepts.

All the components for the closed circuit are integrated in both series: a boost pump acts as a feed pump and control pressure supply, combined make-up and high-pressure relief valves, and a boost pressure relief valve. All pumps can be optimized for specific applications thanks to a large number of individual control devices, while through-drive options enable additional pumps to be fitted with up to the same nominal size. The A10VG covers the 300-bar nominal pressure range with a maximum pressure of 350 bar, while the A4VG high-pressure pump works at a nominal pressure of 400 bar and a maximum pressure of 450 bar.

Compact Motors for Individual Wheel Drive

The MCR radial piston motors (Fig. 5) are especially suitable for compact vehicle concepts. Operating with fixed or shiftable displacement, they provide smooth running motion at low speeds, as well as high speeds for fast transfer travel. Whatever mode they are in, a low level of noise is generated. The design also allows high radial forces to the output shaft. An optional speed sensor, parking brake, and dynamic operating brake create a high level of variance for the development of tailored concepts.

Summary

High-Efficiency Traction Control (HET) is a plug-and-play solution for all-wheel drive activation on compact work vehicles with hydrostatic single-wheel drive without the need for electronics or sensors. The benefits for customers using a HET system can be reduced to the following important points:

- HET improves safety on off-road terrain and on icy or contaminated ground surfaces.

- Thanks to on-demand activation of the all-wheel drive, HET enables users to achieve considerable fuel savings.

- The system design is kept simple with a HET control block connected to proven pumps and motors from the standard product range. This ensures reduced system costs, as well as a high degree of flexibility for individual vehicle concepts.