Hydraulic Output Tripled, Manufacturing Headaches Eliminated

While everyone wants to stay on the road to continuous improvement, many are too busy fighting fires and can’t make the time to begin their improvement journey. One of the biggest headaches that so many manufacturers face is process improvement. A machine shop located in Clearwater, Fla., found a solution that put them ahead of the competition—less stress, fewer late work nights, fewer defective parts, etc.

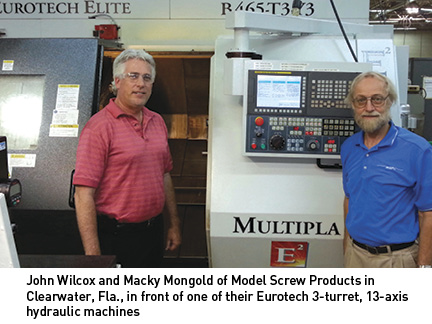

“To stay competitive and keep work here in the United States, we were looking for new ideas and better technology. We needed to improve our output and processes, so we were looking for equipment that would hold extreme tolerances while reducing our load/unload time, cycle time, and scrap rates. The Eurotech machines did this and more. We can complete operations on one machine in one operation,” said Macky Mongold, one of the owners of Model Screw.

Model Screw was founded in 1948 in St. Louis, Mo., by David Feldman. One of Mr. Feldman’s hobbies was building model steam engines. He started the company to build “to-scale” hex head bolts for sale to model builders, hence the name “Model Screw Products.” The company took off and began making precision parts for several defense and commercial companies. In 1972, Marvin Feldman (David’s son) moved the company to Clearwater, Fla, where it has grown to a working team of over 125 people and a 42,000-sq. ft. facility.

Model Screw supplies parts mainly to the hydraulics industry, such as Sun Hydraulics, Parker Hydraulics, and Hydac, as well as to military and automotive companies, such as Chrysler, Caterpillar, John Deere, and Cummins. “For over 60 years, we have built long and strong business relationships with our customers by delivering to their high standards,” explained John Wilcox of Model Screw.

Model Screw supplies parts mainly to the hydraulics industry, such as Sun Hydraulics, Parker Hydraulics, and Hydac, as well as to military and automotive companies, such as Chrysler, Caterpillar, John Deere, and Cummins. “For over 60 years, we have built long and strong business relationships with our customers by delivering to their high standards,” explained John Wilcox of Model Screw.

Model Screw uses the Eurotech machines for many different parts. From spools, sleeves, pistons, and valve bodies, all the parts are completed on one machine and in one operation. “We have reduced our cycle times by over 30%, and in some cases by 50%, plus we’ve reduced our operations and handling. We’ve created a single-step process (one and done!), and this has allowed for less inventory, less labor, less scheduling headaches at multiple machines, and less time/cost of quality checks,” said Wilcox.

Model Screw currently owns both Eurotech 11-axis and 13-axis machines—one dual turret and two triple turret. The B465SY2 is from Eurotech’s dual-turret Trofeo series. This model has a main and a (Clearshift) sub-spindle with Y-axis upper turret, Y-axis lower turret, and live tools on both turrets (2.75″ bar capacity). The B465T3Y3 is from Eurotech’s triple-turret Multipla series. This model boasts a main spindle and three Y-axis turrets, plus sub spindle, C-axis, live tools on all three turrets, and a 2.75″ bar capacity.