Hydraulic Power Units Help Wind Turbine Manufacturer Produce Electricity All Over The World

Eaton is providing key wind power technologies to Guodian United Power Technology Co. Ltd., a subsidiary of China Guodian Corp. Established in 2007, Guodian develops and manufactures large-scale wind turbines for inland, onshore, and offshore applications.

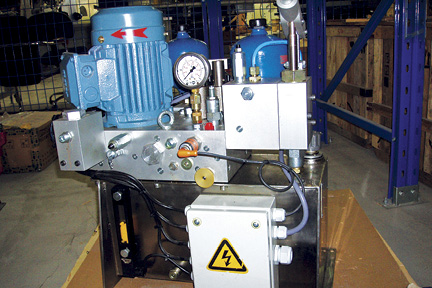

Eaton’s Hydraulics Group in Shanghai, China, is supplying hydraulic power units equipped with Vickers® and Integrated Hydraulics™ screw-in cartridge valves for yaw and shaft-braking functions on Guodian wind turbines produced in Hebei Province, China. Eaton is also supplying Aeroquip® MatchMate Plus® hose and Global TTC crimp fittings for braking system functions. The business is generating approximately $1.5 million in revenues annually for Eaton.

Challenge

Prior to 2007, Eaton provided technical consulting services to China Guodian for Vickers valves on wind turbine systems that it imported for use on its wind farms. China Guodian formed Guodian the following year to manufacture its own wind turbines and decided to open up the power unit business for bids. Eaton was involved in the bidding process.

Meanwhile, Eaton personnel helped modify the hydraulic circuit on the wind turbine technology already in place in order to facilitate easier field installation and maintenance. The modification was made possible with Aeroquip® MatchMate Plus® hose and Global TTC crimp fittings for braking system functions. But in order to stand out from other power unit providers, Eaton China personnel had their work cut out for them.

Solution

Eaton put together a cross-functional team with a solid commitment to being recognized not only as a component supplier, but also a power unit design house backed by a dedicated application engineering team. Eaton’s local production expertise and engineering support, application assistance, senior leadership support, and overall customer care were validated as the team worked through technical requirements, prototype builds, and product testing. With each of its needs satisfied, Guodian made the decision to replace the original specified power units with Eaton hydraulic power units.

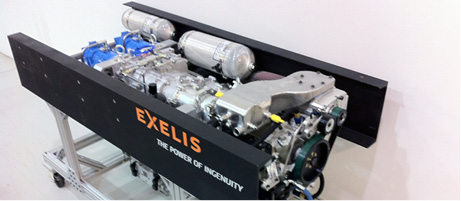

The Guodian Project – A Look at the Technology

Eaton has produced efficient, reliable standard and custom power units since 1960. Each one is built with quality components in facilities that adhere to stringent manufacturing standards. They are available with capacities, control options, manifold and pump options, and configurations to ensure cost-effective operation and optimum productivity while meeting application requirements.

Aeroquip® MatchMate Plus® Hose – The Triple Crown Advantage

The Aeroquip® MatchMate Plus® hose offers advantages in three key areas:

- Pressure – Designed for higher working pressures to provide higher performance levels

- Temperature – Improved working temperature provides higher performance levels

- Abrasion Resistance – Aeroquip DURA-TUFF™ cover is made for longer service life than traditional rubber-covered hose.

The hose features construction technology improvements such as wire-reinforcement designs and processing, new insulation materials, and hose manufacturing processes. Select braided and spiral hose part numbers now meet -40°C to 127°C (-40°F to 260°F).

Global TTC Fittings

TTC fittings are assembled with Aeroquip hose using existing crimp machines. The fittings have a scribe line around the circumference of the socket to easily identify the location where the die cage is positioned for crimping. Typical applications include general-purpose low-, medium-, and high-pressure hydraulics. Pressure is determined by maximum working pressure for hose size and hose end configuration, whichever is less. Through-the-Cover (TTC) Technology Features:

- Advanced design, which provides higher operating and burst pressure

- Elimination of cool-down leakage

- Flat crimp for easier routing

- Compatibility with multiple hose styles to accommodate most application needs

Screw-in Cartridge Valves (SiCVs)

For over 70 years, the Vickers and Integrated Hydraulics product lines have provided customers with quality products and solutions for the industry’s power and motion control needs. While offering the same control functions as traditional hydraulic valves, Eaton’s screw-in cartridge valves are compact, reliable, and economical. The concept of combining multiple cartridge valves into a common manifold offers both the mobile and industrial user substantial cost-saving advantages:

- Response times and efficiency gains, by eliminating many of the hoses, tubes, and fittings necessary in traditional installations

- Few potential leakage points than with conventional valves, ensuring cleaner, safer application environments

- Compact and neat assemblies for economy of space and weight

- Increased ability to withstand vibration, giving optimum machine reliability and performance

- Multiple mounting configurations, which offer maximum design flexibility

- Greater contamination tolerance

- Faster cycle times

- Lower noise levels

- Faster on-sight servicing and troubleshooting

- Resistance to fluid contamination

- Hardened ground steel operating parts

For more information, visit www.eaton.com.