IDEC Upgrades Switches and Relay Sockets with Push-in Wiring

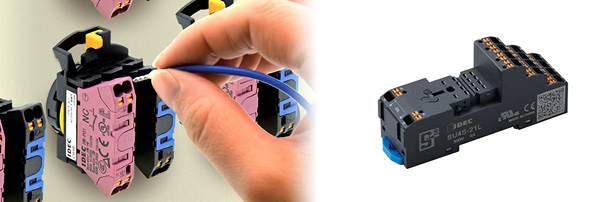

IDEC Corporation has enhanced its HW series of 22-mm switches and pilot lights and its SJ/SU series of relay sockets with new options for push-in wiring technology.

Adding push-in wiring connections gives users extra design options, provides safer and more reliable installation, and minimizes labor costs. Ferrules and stripped solid wires can be connected without tools. There are no screws to torque or tighten. Wires can be removed by pushing down a small orange release pin with a screwdriver. Wiring can be performed by workers of any skill level, and wiring time is reduced by about 55% compared with conventional screw terminal connections.

Constant spring-loaded tension on the wire maintains a reliable connection and improves vibration resistance. The entire push-in structure is finger-safe, so workers never touch the conductors.

Push-in contact blocks are compact, taking less depth than traditional versions. This improves working space inside a panel and potentially enables enclosures to be downsized. Connections are angled to facilitate wire entry, and the contact blocks feature a test point for insertion of a multimeter probe. Both switch contact block and relay socket electrical connections are rated IP20 finger-safe.

For more information, call (800) 262-IDEC, or visit http://www.idec.com/push-in.