IMTS 2018

September 10 – 15, 2018 • McCormick Place • Chicago, Il

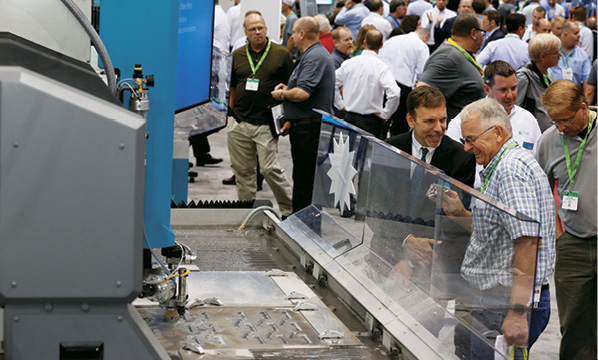

The largest manufacturing exposition and technology conference is taking over McCormick Place in Chicago, Illinois, starting Monday, September 10 through Saturday, September 15. One of the most highly anticipated trade shows in the industry, the International Manufacturing Technology Show (IMTS) will feature more than 2,400 companies exhibiting from 117 countries.

The trade show’s sponsor, the Association For Manufacturing Technology (AMT), played host to the third largest number of registrations at the McCormick Place complex in 2016, and they hope to top that number this year. If successful, this will be made possible by the conference organizers, who are dividing the exhibitors into pavilions curated based on industry, technologies and solutions. The configuration will help facilitate better networking and increase the dissemination of ideas across a variety of perspectives in each area of focus. Attendees will not only get to listen and learn, but also share, explore and collaborate.

IMTS attractions are another reason why thousands of manufacturing industry professionals attend this biannual event. From AMT’s Emerging Technology Center to the Miles for Manufacturing 5K, the conference endorses exercising the body as well as the mind while sharing ideas and insights with a cavalcade of exhibitors over the six-day event. The largest conference dedicated to global manufacturing technology in the Western Hemisphere, IMTS is determined to have every participant leave with more insight in what is working, what isn’t working and what’s to come.

One of the most anticipated attractions of the 2018 IMTS expo is the Smartforce Student Summit, a program designed to engage students and teachers from elementary to post-secondary school with potential career ideas and a look inside the manufacturing technology industry. New advanced technology showcases, learning labs, and hands-on challenges are designed to spark the next generation of makers in robotics, generative design, Industrial Internet of Things, and much more. For students unsure of their specific path in the manufacturing industry, hosts will provide an overview of the entire manufacturing process to help soon-to-be young professionals decide if they’re better suited for 3D printing or automation or data acquisition or machine and tool monitoring, just to name a few. There’s also an Air Rocket Challenge!

Integrated across numerous presentations throughout the pavilion, thought leaders in multiple disciplines are ready to share their fresh concepts and constructive analysis in events dedicated to specific industries within manufacturing technology. For example, GAMS (Global Automation Manufacturing Summit), the Industrial Laser Conference, and the Top Shops Workshop all give IMTS a conference-within-a-conference dynamic that will insure that the week’s programming will never have a dull moment.

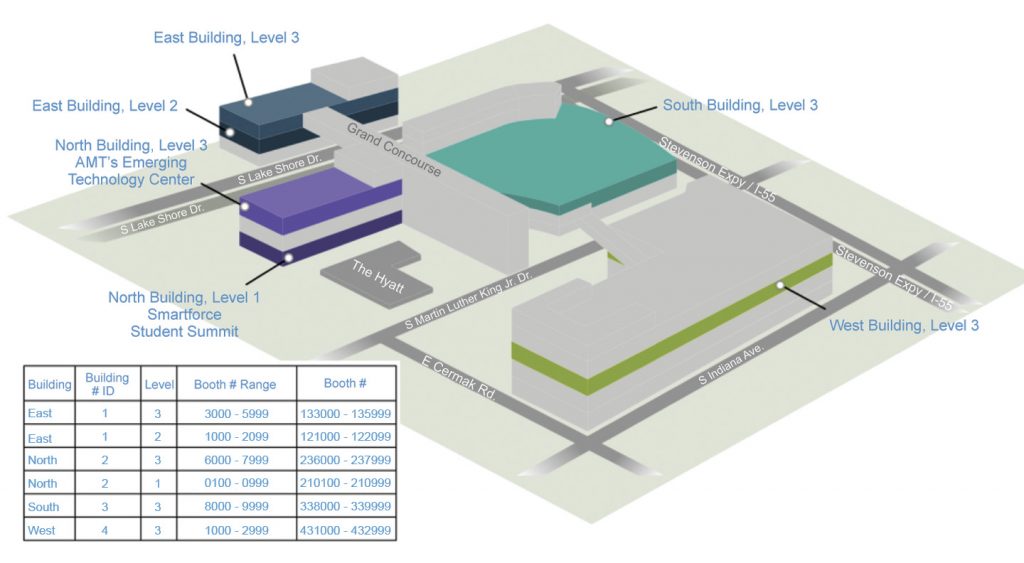

Click on map to enlarge.

FLUID POWER EXHIBITORS

Advertisers are in bold

Company • Booth

Advanced Machine & Engineering • 121117, 432423

Airtec Pneumatics, Inc. • 121670

AMETEK • 135642

Anson Hydraulics International Co., Ltd.• 135257

API Heat Transfer • 135089

API Srl • 134446

ARGO-HYTOS, Inc. • 134975

Ashun Fluid Power Co., Ltd. • 135178

Balluff, Inc. • 134062

Bansbach • 135066

Bimba Manufacturing Co. • 134825

Busch Vacuum Pumps & Systems • 121571

Buyfittingsonline.com/QMC Technologies, Inc. • 121588

Canfield Industries • 121558

CAPLUGS • 121282

CO-AX Valves, Inc. • 236990

Deublin Company • 121003

DURA-BAR • 431272

Elesa USA Corp. • 121265

ENERPAC/Milwaukee Cylinder • 431426

Epicor Software Corp. • 133324

EPLAN Software & Services • 134424

Eurotech Elite • 134533

Extrude Hone LLC • 237108

FAI Filtri U.S., LLC • 121901

Faster, Inc. • 121595

Festo Corp. • 215128, 134357

FG Filtration Company • 135072

FOR S.p.a. • 134444

Fuchs Lubricants Co. • 431646

Company • Booth

Gehring • 236723

H B Hydraulics Co., Ltd. • 135255

HYDAC Technology Corp. • 135062

ifm efector, inc. • 121828

Igus Inc. • 134521

Jiangsu Everest Technology Co., Ltd. • 134363

Jumo Process Control, Inc. • 134878

J. W. Winco, Inc. • 121441

Kaesar Compressors, Inc. • 236643

KTR Corp. • 121041

Kurt Manufacturing Co. • 432433

Lexair, Inc. • 431322

Mobil Industrial Lubricants • 339292

Nachi America • 432024

National Filters, Inc. • 135177

Prevost Corp. • 121021

Quaker Chemical Corp. • 431949

Rosedale Products, Inc. • 121436

SCHUNK, Inc. • 432010

Servometer • 121550

Seven Oceans Hydraulics Industrial Co., Ltd. • 135170

SIKO Products, Inc. • 134245

SMC Corporation of America • 121238

SUCO Technologies • 134979

SunSource • 121657

Tolomatic • 134436

Volz Gruppe GmbH • 431972

Winner Hydraulics Corp. • 135182

Yutien Hydraulic Industry Co., Ltd. • 135176

Zimmer Group US, Inc. • 134352

IMTS 2018 Sessions

Adopting On-Demand Manufacturing Models to Drive Supply Chain Efficiencies, Minimize Risks and Reduce Costs #IMTS02

10:00 AM – 10:55 AM | W192-B

With product life cycles getting shorter and industry trends driving mass customization of products, on-demand manufacturing represents an evolution in procurement and supply chain management thought.

Advanced Grinding Takes Aerospace Parts to New Heights #IMTS01

10:00 AM – 10:55 AM | W192-A

Efficient Manufacturing Down to a Lot Size of 1 #IMTS03

10:00 AM – 10:55 AM | W192-C

The customization of products in fields such as medical and automotive engineering result in ever greater demands on the economic production of small lots.

How to use Active Laser Guarding Systems in High Power Laser Processes #IMTS04

11:00 AM – 11:55 AM | W193-A

This paper discusses how active laser guarding developments have become ever more necessary in the role of laser safety and the prevention of injury due to high power laser radiation.

Metal Additive Manufacturing Myths: The truth about powder reuse and its effect on mechanical properties #IMTS06

11:00 AM – 11:55 AM | W194-A

Automated NC Programming and Combating the Skilled Labor Gap #IMTS05

11:00 AM – 11:55 AM | W193-B

Reducing Calibration Risks in Your Measuring Systems: Leveraging Standards and Training #IMTS07

1:15 PM – 2:10 PM | W192-A

Mastering the Monkey’s Paw: Using Generative Design and 3D Printing to Make Wishes, Not Curses #IMTS08

1:15 PM – 2:10 PM | W192-B

This talk will explore generative design tips for how to know what questions to ask, how to identify and avoid the wrong questions.

Achieve Full Process Optimization #IMTS09

1:15 PM – 2:10 PM | W192-C

Goulding and Funke explain how shops that make continuous improvement a core part of their strategy should seek out a process optimization partner.

Opening Up Design Freedom and Mass Customization Through 3D Printed Lattices #IMTS10

2:15 PM – 3:10 PM | W193-A

Latest Changes in Government Regulations Affecting Solvent used in Parts Cleaning #IMTS11

2:15 PM – 3:10 PM | W192-B

The Beginners Guide to IIOT/Industry 4.0 #IMTS12

2:15 PM – 3:10 PM | W194-A

This presentation will show why IOT is important to you and your manufacturing business, and it will provide some basic implementation strategies.

Waterjet Integration into a Machine Shop #IMTS13

3:15 PM – 4:10 PM | W192-A

Attendees will learn how to design and optimize manufacturing processes to incorporate abrasive waterjet cutting.

Reducing Waste with Non-Destructive Environmentally Sustainable Dry Ice Cleaning #IMTS14

3:15 PM – 4:10 PM | W192-B

Participants will be able to determine how their production and quality can be improved and how the process affects the environment.

The Path to Smarter Manufacturing Through Connectivity on the Shop-Floor #IMTS15

3:15 PM – 4:10 PM | W192-C

Tool Lifecycle Management 4.0 – In line with Industry 4.0 Using Integrated Tool Data Management Solutions #IMTS16

9:00 AM – 9:55 AM | W192-A

5-Axis Machining – Some Best Practices #IMTS17

9:00 AM – 9:55 AM | W192-B

Achieving Lean Manufacturing through Reuse and Recovery of High-Value Metallic Wastes and Academic Partnerships #IMTS18

9:00 AM – 9:55 AM | W192-C

AM is Not Just for Rapid Prototyping Anymore #IMTS19

10:00 AM – 10:55 AM | W193-A

As AM solutions mature they are enabling the transition from rapid prototyping to production. The most compelling examples are those which allow product designers to pursue ideas which were previously impossible to manufacture.

Automation: The Missing Link to Productivity in Part Programming #IMTS20

10:00 AM – 10:55 AM | W193-B

Technological Advancements within Ultra Sonic Milling, Friction Stir-Welding and 3D Printing Markets #IMTS21

10:00 AM – 10:55 AM | W194-A

Digital Productivity Solutions #IMTS22

11:00 AM – 11:55 AM | W192-A

With the field of digital productivity solutions, KOMET® is setting the course for the digital future of machining. In a changing market situation the demand for custom solutions is growing while the requirement for standard tooling is decreasing.

How “Walk-Up Metrology” Offers QC Versatility from Manual One-Feature Measurements to Semi-Automated Multi-Dimensional Testing #IMTS23

11:00 AM – 11:55 AM | W192-B

Improving Your Spindle Up-Time with the Right Workholding #IMTS24

11:00 AM – 11:55 AM | W192-C

Smart Manufacturing: Empowering Small-to-Medium Manufacturers with the Tools to Compete #IMTS25

1:15 PM – 2:10 PM | W193-A

The Blue Arc® Metal Removal Process Update: A Case Study in the Benefits of Vendor Collaboration #IMTS26

1:15 PM – 2:10 PM | W193-B

In today’s current manufacturing environment, we are facing more complicated, multi-discipline processes. We are addressing these complicated challenges with a dwindling resource base. The ever-growing skills gap will force us to work differently in the future and the future is NOW.

Tying It All Together: The Crucial Impact of Traceability in the IIOT #IMTS27

1:15 PM – 2:10 PM | W194-A

Innovations in Precision Bore Finishing: How advancements in honing and lapping take today’s bore tolerances to new levels #IMTS28

2:15 PM – 3:10 PM | W192-A

This presentation will discuss the rapid advances in honing and lapping, including bore geometry, surface tribology (plateau finishes, bearing ratios), burr conditions (torn and folded metal) and edge condition, among others.

Revolutionizing Production of High Performance, Hybrid Composite Structures with Stratasys Additive Manufacturing #IMTS29

2:15 PM – 3:10 PM | W193-B

Manufacturing as Code (MaC): An Innovative Approach to Agile Manufacturing #IMTS30

2:15 PM – 3:10 PM | W192-C

Technology Integration and its Profound Impact for Manufacturers #IMTS31

3:15 PM – 4:10 PM | W193-A

Process Monitoring and Control in Metal 3D Printing: How to Tame the Tiger #IMTS32

3:15 PM – 4:10 PM | W193-B

Selective Laser Sintering: Additive Manufacturing with Polymers is Closer Than You Think #IMTS33

3:15 PM – 4:10 PM | W194-A

Agile Manufacturing – How to produce a lot size of one economically? #IMTS34

9:00 AM – 9:55 AM | W192-A

- How to answer to constantly changing customer demands quickly?

- How to introduce a new part into your manufacturing stream easily?

- How to produce small lots economically, starting from a single lot of one?

Augmented Reality, Machine Learning, Fringe Pattern…oh my…an introduction to the terminology and technology that will drive quality manufacturing into the next decade #IMTS35

9:00 AM – 9:55 AM | W192-B

Digitalization in Machine Tool Manufacturing – You’re Closer Than You May Think #IMTS36

9:00 AM – 9:55 AM | W192-C

Grow Your Company While Conserving Cash #IMTS37

10:00 AM – 10:55 AM | W193-A

High Performance Grinding (HPG) of Nickel-based Superalloys #IMTS38

10:00 AM – 10:55 AM | W193-B

Ongoing Improvement with Indexable Drill Head Technology & Productivity Impact #IMTS39

10:00 AM – 10:55 AM | W194-A

Pat Cline, product manager for ISCAR, a world leader in cutting tool innovation, shares the evolution of the self-clamped indexable head drilling and the benefits of applying the most recent technology.

Enabling Yield Improvement in 3D Printing Process Chain #IMTS40

11:00 AM – 11:55 AM | W192-A

Cost Justification #IMTS41

11:00 AM – 11:55 AM | W192-B

This presentation will demonstrate how you can accurately justify making an investment in new equipment that will yield the lowest piece-cost.

7DoF Machine Control Drive Automation in Groundbreaking Projects #IMTS42

11:00 AM – 11:55 AM | W192-C

Industry 4.0 and Model Based Enterprise for Quality Assurance – Inspection Efficiencies, Design Inputs, and Manufacturing Outputs #IMTS43

1:15 PM – 2:10 PM | W193-A

Latest Innovations in Laser Marking #IMTS44

1:15 PM – 2:10 PM | W193-B

Machine Performance and Value Hang in the Balance #IMTS45

1:15 PM – 2:10 PM | W194-A

The machines must be simplistic in design – which is easy enough – yet innovative and with as much capability as possible while still maintaining affordability.

Minimum Quantity Lubrication (MQL)—Benefits and Lessons Learned for Production Implementation #IMTS46

2:15 PM – 3:10 PM | W192-A

Achieving Maximum Productivity by Addressing the Weakest Link – Your Connection #IMTS47

2:15 PM – 3:10 PM | W192-B

Transform Traditional Manufacturing to Manufacturing-as-a-Service #IMTS48

2:15 PM – 3:10 PM | W194-A

This talk will discuss the technology required to build an agile customer centric manufacturing operation, enabled by a digital ecosystem of continuous feedback, that will automate from design to delivery and make MaaS a reality for manufacturing today.

The Connected Machine Shop: Building the Digital Thread #IMTS49

3:15 PM – 4:10 PM | W192-A

Learn how a machine shop’s value stream will increase significantly through advanced data acquisition and analysis, machining strategy development and machining process security.

Standards Framework – What is the right approach to be effective? #IMTS50

3:15 PM – 4:10 PM | W193-B

The Value of Reliability/Predictive Maintenance #IMTS51

3:15 PM – 4:10 PM | W194-A

Delivering Efficiencies in Certified 3D Printed Aerospace Parts #IMTS52

9:00 AM – 9:55 AM | W192-A

Turning to New Heights #IMTS53

9:00 AM – 9:55 AM | W192-B

How Automation & Optimization Software Can Maximize Shop Floor Capabilities #IMTS54

9:00 AM – 9:55 AM | W192-C

Using 3D Optical Scan Data to Enhance 3D Printing Capabilities #IMTS55

10:00 AM – 10:55 AM | W192-A

Industry 5.0 – the “human touch” revolution #IMTS56

10:00 AM – 10:55 AM | W193-B

Craft beers, individually designed furniture, hi-tech products with a personal touch – almost anything that bears the imprint of human craftsmanship, and that helps the individual consumer express his or her own unique identity. A new consumer macro-trend is emerging.

Maximizing Manufacturing Productivity in the Information Age #IMTS57

10:00 AM – 10:55 AM | W192-C

3-Dimensional Shop Floor Measurements To Improve Yield #IMTS58

11:00 AM – 11:55 AM | W192-A

A Paradigm Shift in Shop Floor Scheduling: Can LEAN / TOC Principles Make Finite Capacity Scheduling Simpler and More Effective? #IMTS59

11:00 AM – 11:55 AM | W192-B

- How to apply Little’s Law to lower WIP and improve FLOW through the shop floor

- Uncover the best priority mechanism to focus on the right job at all times

- How consciously managing ‘buffer time’ on your jobs improves on-time delivery

Choosing Part Optimization Strategies #IMTS60

11:00 AM – 11:55 AM | W192-C

Light Weight Engineering in Workholding #IMTS61

1:15 PM – 2:10 PM | W193-A

Modern Workholding Strategies for Swiss-type Machining #IMTS62

1:15 PM – 2:10 PM | W193-B

How Virtual Machining CAM Technology Solution Improves Manufacturing Workflow #IMTS63

1:15 PM – 2:10 PM | W194-A

Redefining the Future of Manufacturing with Metal 3D Printing #IMTS64

2:15 PM – 3:10 PM | W193-A

Seven Ways to Boost Your Grinders’ Production #IMTS65

2:15 PM – 3:10 PM | W192-B

Smart Manufacturing & Changing Global Supply Chains #IMTS66

2:15 PM – 3:10 PM | W192-C

HP Materials and Open Platform for Additive Manufacturing #IMTS67

3:15 PM – 4:10 PM | W193-A

The Next Step: Taking 3D Printing from Prototyping to the Production Floor #IMTS68

3:15 PM – 4:10 PM | W193-B

Manufacturers will have to overcome significant obstacles to incorporate supporting strategies, such as workflow automation, workforce education and big data.

Trueing of Diamond Grinding Wheels #IMTS69

3:15 PM – 4:10 PM | W194-A