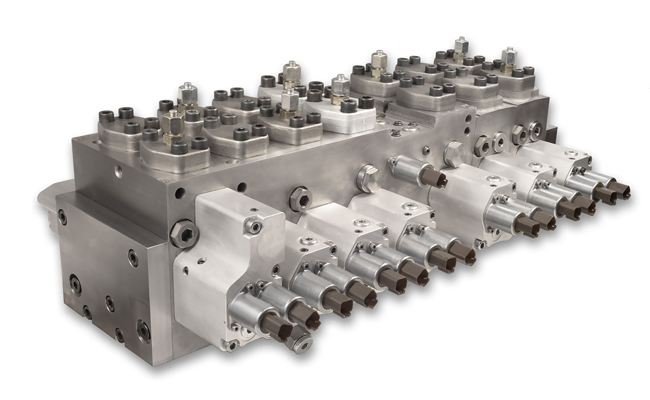

Linde Hydraulics Introduces New Valve Block

Linde Hydraulics recently introduced its next generation of control valves.

Linde Hydraulics recently introduced its next generation of control valves.

The new valve block VW 22/18 M5-03 for the open circuit is characterized by its modular design. The system is made up of a center manifold (monoblock) with five sections which includes a pressure relief function. The center monoblock is machined so that up to three additional sections can be added on each side of the block, making it possible to address specific needs.

Various functions can be selected for the additional sections, which are ideally suited for a wheeled excavator. In addition to standard options such as boom or lift-regeneration, anti-drift, and return-flow bypass, Linde Hydraulics now also offers rod-to-head-regeneration for other cylinders and an innovative float function for the excavator.

Float function

In the context of control valves, the term “float” refers to a valve function that allows a cylinder to move with little resistance while both the rod and cap ends are open to the reservoir.

In conventional control valves where the A and B ports are blocked, the actuator is locked in position by the fluid and cannot move when impacted by external conditions. In certain applications, however, it is desired that a cylinder yields to external forces by retracting or extending using the float function. This is particularly important to avoid either increased wear of the attachment on a hard surface or damage to a sensitive surface by the attachment. A typical example is avoiding damage to the deck while unloading a ship.

In the past, the float function has been used mainly in applications with excavating functions such as in the lift or bucket of a wheel loader. Now it can also be easily added for use in excavators.

Through an innovative solution, Linde Hydraulics implements the float function with only a small additional piston in the valve. Compared to conventional solutions, this float function saves space and can be used at lower speeds.

Rod-to-head-regeneration

Rod-to-head-regeneration is used for cylinder functions where there is high actuator speed at a low-pressure level. In conventional systems, when the operator uses the joystick for fast movements under a light load, all the flow must come from the pump. With the rod-to-head-regeneration, the pump only needs to provide flow to displace the rod. In this way, much more dynamic movements are possible with reduced flow from the pump. As soon as the load on the cylinder increases to a pre-set level, rod-to-head-regeneration switches off automatically.

Return-flow bypass

Symmetrical valves with return bypass are used when functions operate for long periods and require high flow rates, as with travel drives in mobile excavators. A large portion of the return flow is directed through the return bypass, which is controlled by a simple pin, reducing return line pressure and consequent energy loss. This produces noticeable fuel savings when compared to conventional valves. With this function, the make-up valves can draw flow from the tank during downhill travel, thus avoiding cavitation.

Anti-drift

Anti-drift is used in lifting functions when a specific position must be secured and guaranteed to be held, for example, in the crane operation of an excavator. The anti-drift function uses an additional valve to prevent the leakage that occurs in conventional control valves. This valve is located between the control piston and the actuator and provides a positive seal, while the section is not actuated.

Boom or lift-regeneration

Boom or lift-regeneration is used for lifting functions, such as the boom of the excavator. In this function, the weight force is used during lowering, and the oil flow from the cap end of the cylinder is partially diverted to the rod side. In this way, very little flow is required from the pump. In addition, the tendency to cavitate is eliminated. The flow saved in this process is thus directly available for other functions.

This third generation of valve technology is a suitable complement to the existing second generation (three sections) due to the compact five section monoblock and is also perfectly matched to the wheeled excavator.

The control valve is available in two nominal sizes: nominal size 18 with a max. flow rate of 250 l/min (66 gpm) and size 22, which allows a max. flow rate of 350 l/min (92 gpm).

Linde Synchron Control (post-compensated) is used as standard in the monoblock, while a choice can be made between pre- and post-compensated for the option sections. Both hydraulic and electrohydraulic controls are possible.

The valve block is already in use at a pilot customer in a wheeled excavator and is planned for use with material handlers.

For more information, visit www.linde-hydraulics.com.