The Long Road to Safety Certification

By Charles Butcher, Justin Shelton (Hoerbiger), and Eike Stratmann (Hoerbiger)

Hydraulic locking units for passenger restraint gain TÜV approval

Ever had a bad dream involving a roller coaster? It’s reassuring to know that real-life amusement park rides are extremely safe, thanks in no small part to hydraulic passenger restraint systems.

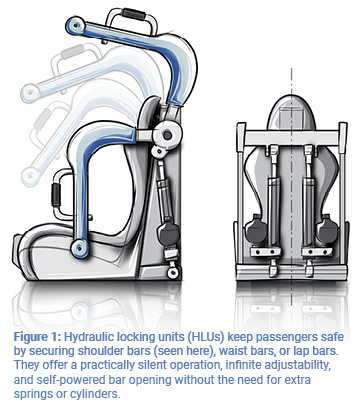

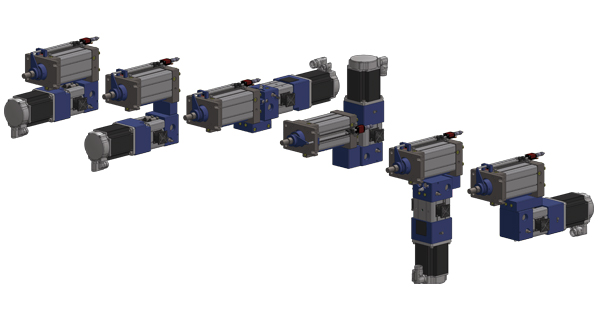

For many years, Hoerbiger has supplied ride manufacturers with hydraulic locking units (HLUs). The units are used to position the restraining device – a shoulder bar, waist bar or lap bar – and secure it in place. They have several advantages over purely mechanical systems, notably infinitely variable adjustment and a practically silent operation.

More recently, the company has obtained safety certification for its HLUs from the respected German authority, TÜV SÜD. From idea to completion, the process has taken three years. With such an arduous journey to obtain certification, why decide to undergo this process, and why did it take so long?

More recently, the company has obtained safety certification for its HLUs from the respected German authority, TÜV SÜD. From idea to completion, the process has taken three years. With such an arduous journey to obtain certification, why decide to undergo this process, and why did it take so long?

HOERBIGER sought TÜV certification to reassure its customers and ease their workload. The company has always designed and manufactured HLUs to the highest safety standards, and the new certification requirements have not changed that. For ride manufacturers, however, TÜV approval now means quicker and simpler specification, ordering, and commissioning. The products are certified to meet all the relevant standards – ISO 17842–01:2015, DIN EN 13814, prEN 13814:2016, and ASTM 2291–15 – and all the documentation is easily available. TÜV SÜD is also well respected in the amusement park industry.

Not a walk in the (amusement) park

Scary rides test the physical limits of both passengers and machinery, so it should be no surprise that the requirements for TÜV certification in this field are extremely tough. In short, TÜV SÜD had to review the design basis of Hoerbiger’s HLUs, approve the company’s procedures for designing and testing the units, and conduct annual audits to make sure standards are maintained.

The first step was to submit detailed design calculations, including finite element modeling (FEM), to show that the units can withstand any foreseen loads in both normal operation and emergencies.

Next, TÜV SÜD looked at the actual materials of construction used. The company was requested to prove that it can document the source and quality of every batch of material, in terms of both the supplier’s records and its own incoming goods inspections. Material batches must also be related to production batches, and ultimately, to the unique serial number of each finished unit.

Demonstrating the strength and other engineering properties of the materials to TÜV SÜD’s satisfaction required our company to develop new statistical test procedures. As a result, we are confident in the strength of the materials exceeds that required by the functional safety analysis.

In production, the company had to show that the manufacturing process is carried out consistently, and that there is no possibility of contamination during assembly. The fact that Hoerbiger Micro Fluid GmbH already had ISO 9001 certification was an advantage here, so their precautions included:

- strict packaging regulations for suppliers

- comprehensive incoming goods inspections for oil-carrying parts using microscopy

- additional cleaning of individual parts

- maximum purity of compressed air, water, hydraulic oil and solvents

- additional rinse cycles during manufacture

Once assembly is complete, it is time to test the finished units. The company reinforced its originally stringent test procedures by investing in new test benches and equipment. Every finished unit is inspected for dimensional tolerances, stroke length and force, leakage, and manual emergency actuation function.

Finally, a burn-in test subjects each HLU to more than 1,050 cycles under a predefined load, with tight tolerances for the allowable stroke length.

Ensuring maximum reliability

DIN EN 13814 specifies an operating life of 35,000 hours, or in Hoerbiger terms, 5 million load cycles (the company additionally designs for a service life of 7 years). The combination of design calculations, material specifications, material testing, and finished-goods testing achieves a failure rate of less than one per billion operating hours (<10–9 /h).

DIN EN 13814 specifies an operating life of 35,000 hours, or in Hoerbiger terms, 5 million load cycles (the company additionally designs for a service life of 7 years). The combination of design calculations, material specifications, material testing, and finished-goods testing achieves a failure rate of less than one per billion operating hours (<10–9 /h).

Each delivered unit meets the special requirements of prEN 13814:2016 for the safety integrity of passenger restraint systems, and is rated to Performance Level e ready (PLe) under the prEN 13814:2016 standard.

In summary, obtaining TÜV certification for these HLUs has required a great deal of work with very few changes to the physical product. For such safety-critical equipment, however, the company believes that the resulting peace of mind – and simplified business procedures for customers – has been well worth the effort.

Keeping you safe upside down

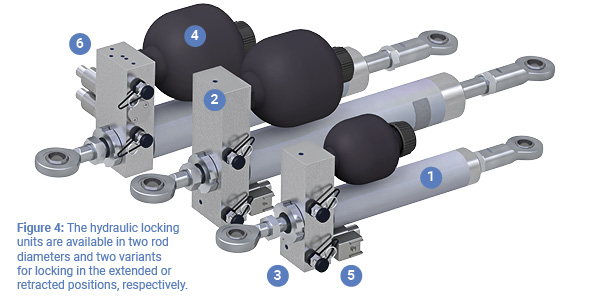

At the heart of a hydraulic locking unit (HLU) is a bolted twin-pipe cylinder (1) that secures the restraining bar. The inner pipe guides the piston rod with the piston; the outer pipe carries oil from the rod side to the flange-mounted connection block on the cylinder base.

The connection block (2) accommodates a diaphragm accumulator, a check valve, and two ports (3) used to fill and pressurize the unit at the factory.

The accumulator (4) precharges the unit to a predefined pressure and accepts the oil displaced by the piston rod as it retracts. The energy stored in the accumulator during closing is also used to open the restraining bar at the end of the ride, making the HLU a self-contained system requiring no extra springs or cylinders.

The poppet check valve (5) locks the piston rod in place during the ride by preventing backflow of oil. Two different configurations are available – locking in the extended and retracted rod positions, respectively – to suit different ride designs. The valve has a hardened seat for minimum leakage and maximum reliability.

At the end of the ride, the check valve is actuated electromechanically to open the restraint bar. In an emergency, the check valve can also be opened manually.

An optional second valve (6) increases passenger comfort by preventing the restraint bar from closing too tightly during the ride.

Nice buy no redundancies? What happens if the accumulator, check valve or block fails during the ride? Why some manufacturers (KMG to say) uses JUST this system for harnesses and not a secondary back up locking system in case the first one fails? (Like Mondial using a back up belt like to secure the restrain)

Hi Paul

I inspect amusement rides – and all the recent KMG rides use a single trapped fluid system – with status monitoring interlocked to prevent starts unless the restraints are locked.

They ALL use a secondary lock system – also monitored and interlocked – as a backup should the primary fail.